Tel/WhatsApp

Tel/WhatsApp

Oil sludge treatment pyrolysis plant can convert oil sludge into fuel oil, combustible gas and soil through high temperature. Using a pyrolysis plant to treat oil sludge has advantages such as easy operation, high environmental protection, maximum economic benefits and so on. And it's a widely used method of waste oil sludge treatment worldwide. Next, I will introduce our company's two different types of oil sludge treatment plants.

The pyrolysis products of oil sludge treatment plant

The pyrolysis products of oil sludge treatment plant

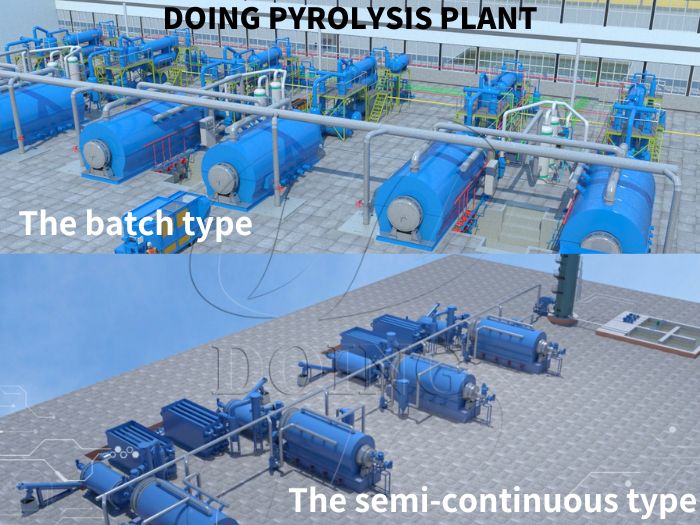

DOING has batch and semi-countinuous type oil sludge treatment plants for sale. These two types of plants don't have high requirements for raw material, multiple forms of oil sludge can be processed by it. Therefore, whether your raw material is solid, semi-fluid or liquid, you can choose our oil sludge pyrolysis plants. Also, for different forms of oil sludge, our pyrolysis machine is equipped with different feeders such as pump, feeding auger, feeding hopper and feeding conveyor, etc..

DOING batch and semi-countinuous type oil sludge treatment plants

DOING batch and semi-countinuous type oil sludge treatment plants

1. The batch type treatment plant

▪ The reactor is made of boiler plate material, which can withstand high temperatures and is also very durable by direct heating. In addition, the material of the reactor can also be customized, such as 304/316/310S stainless steel.

▪ Oil sludge with an oil content of over 30% is easy to bond. To avoid this, we have added a decoking device in the reactor to prevent wall sticking and difficult cleaning.

▪ After the pyrolysis is complete and the reactor is cooling down, then can discharge. Two types of discharge methods, side and rear, which can be customized according to customer needs.

▪ Processing capacity: 1/2/5/10/12/15/18/20T/D

▪ Efficiency: 1 furnace per day

Batch type oil sludge treatment pyrolysis plant

Batch type oil sludge treatment pyrolysis plant

2. The semi-continuous type treatment plant

▪ The reactor is heated by indirect heating method, which extends the service life of the reactor. And the material of reactor is the same as the reactor of batch type.

▪ The semi-continuous oil sludge treatment plant for sale is the same as the batch type, it's also equipped with a decoking device.

▪ There is no need to cool the reactor, the slag discharge and pyrolysis can be performed simultaneously. By cooling the slag conveyor for discharging, the operating efficiency is higher.

▪ Processing capacity: 12/15/18/20T/D

▪ Efficiency: 3 furnaces in 2 days. If you have high efficiency requirements, you can choose a semi-continuous oil sludge treatment plant.

Semi-countinuous type oil sludge treatment plant

Semi-countinuous type oil sludge treatment plant

Regardless of batch type or semi-continuous type, they all have their own characteristics and can achieve oil sludge pyrolysis. If you are interested in our oil sludge treatment pyrolysis plants for sale, please feel free to contact us at any time. Our sales manager will introduce you to more detailed information and design a unique oil sludge treatment solution for you according to your actual situation.