Tel/WhatsApp

Tel/WhatsApp

On 24 October 2025, a 50-tonne industrial continuous oily sludge pyrolysis production line supplied by DOING was successfully installed in Inner Mongolia, China.

DOING continuous oily sludge pyrolysis production line

The Chinese client involved in this collaboration is a comprehensive group specialising in environmental engineering, pollution control, and solid waste disposal. The client proactively contacted DOING as early as 25 February 2025, expressing interest in sludge treatment. They confirmed site readiness, feedstock sourcing, and relevant environmental permits, demonstrating mature project preparation capabilities.

Prior to engaging DOING, the client had researched multiple pyrolysis equipment manufacturers and conducted on-site inspections of three operational projects to gain a thorough understanding of the industry landscape. What impressed the client was DOING's meticulous attention to professional detail – as the manufacturer, DOING proactively requested access to the client's environmental assessment report. This meticulousness made the client realise that the environmental assessment report explicitly mandated the use of ‘continuous intelligent processes,’ which intermittent pyrolysis lines fundamentally could not fulfil for compliant production. This critical point became a pivotal turning point for subsequent cooperation between the two parties.

DOING continuous oily sludge pyrolysis production line installation site

This project utilizes DOING's mature continuous pyrolysis technology, enabling efficient reduction, harmless disposal, and resource recovery of sludge.

Equipment Type: 50-tonne industrial continuous waste oil sludge pyrolysis production line

Core Equipment: Continuous feeder, continuous pyrolysis reactor, continuous condenser, continuous slag discharger, exhaust gas purification unit, and fully automated PLC control system

Coke Removal Structure: Pyrolysis furnace liner constructed from 304 stainless steel with integrated coke removal device

Delivery Schedule: Shipments in batches within 45 days of contract signing (main furnace prioritised), with full completion within 60 days

Service Model: Client-led installation with DOING engineers providing full on-site guidance

Output products include pyrolysis oil, carbon residue, and synthesis gas, with an overall resource recovery rate exceeding 90%. The process complies with hazardous waste pollution control standards and local environmental requirements.

DOING continuous oily sludge pyrolysis production line installation site

Throughout the four-month decision-making process, despite project suspensions and negotiations over contractual details, the client ultimately chose DOING for three key reasons:

Tailored solutions

Initially, the client indicated budget constraints. DOING first proposed four batch-type oil sludge pyrolysis production lines for consideration. Subsequently, in response to the client's environmental assessment report requirements, DOING swiftly adjusted its strategy towards a ‘continuous intelligent pyrolysis process’ solution. Equipment configurations were optimised specifically for the characteristics of oil sludge feedstock, ensuring the precision and feasibility of the proposal. This effectively mitigated the risk of project stagnation due to process incompatibility.

Prompt Response and Comprehensive Service

When the client requested last-minute adjustments to the workshop layout, DOING's engineers rapidly revised the drawings, submitting the second and third versions that very evening. Upon the client's request to visit operational projects, the project lead promptly coordinated an on-site tour of a facility running reliably for over three years, enabling the client to witness firsthand the equipment's dependability.

Real-world Case Support

The client observed DOING three 30 ton continuous pyrolysis production lines operating in other regions, noting stable oil output, high automation levels, and superior product quality. This direct experience proved far more persuasive than any written description.

DOING other continuous pyrolysis production line project

DOING continuous oily sludge pyrolysis production line installation site

As a National High-Tech Enterprise in the solid waste pyrolysis sector, DOING consistently upholds the following principles:

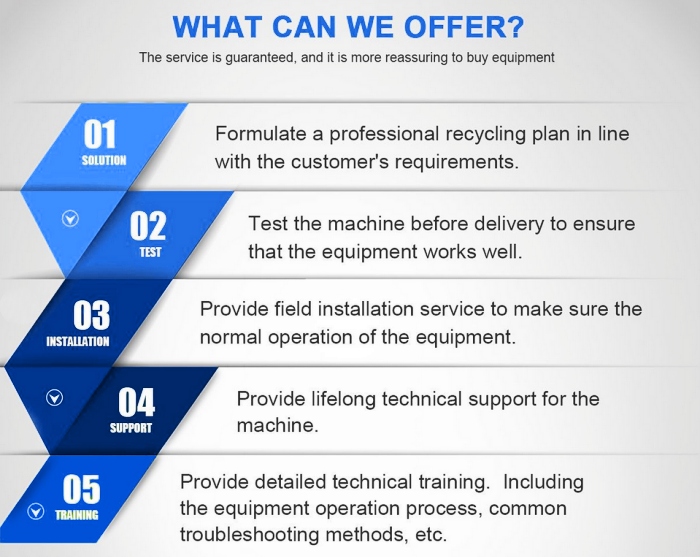

Customer-Centric Approach: Providing bespoke solutions from environmental assessment adaptation and process route selection to site planning.

Technology-Driven Philosophy: The design of continuous oily sludge pyrolysis production lines fully accounts for practical operating conditions including anti-coking, corrosion resistance, and extended operational cycles. Process details are optimised, featuring an internal energy ball decoking structure within the main furnace: these balls enhance material dispersion and improve heat transfer efficiency. As the reactor rotates, the energy balls contact the inner walls, scraping and frictioning away existing coke deposits while effectively preventing new formation. Typically crafted from corrosion-resistant steel, these balls are reusable.

Aiming for long-term collaboration: Even when clients undertake self-installation, DOING deploys resident engineers to provide on-site guidance, ensuring smooth commissioning.

DOING continuous oily sludge pyrolysis production line manufacturer

The successful implementation of this project in Inner Mongolia, China, reaffirms DOING's service philosophy: ‘Earning respect through expertise, delivering on promises with capability.’ We extend our gratitude to our Chinese clients for their support. DOING remains committed to assisting more enterprises in resolving hazardous waste disposal challenges through robust technology, reliable equipment, and sincere service.