Tel/WhatsApp

Tel/WhatsApp

Oil sludge, a hazardous and complex mixture of oil, water, and solid particles, is a significant byproduct of the petroleum industry. Traditional disposal methods like landfills and incineration are increasingly restricted due to environmental concerns. Pyrolysis technology—a thermochemical decomposition process in the absence of oxygen—emerges as a superior solution. It doesn't just manage and treat the waste oil sludges; it transforms it, simultaneously achieving profound environmental protection and generating tangible economic profits.

DOING oil sludge treatment pyrolysis plant

1. Significantly Reduced Environmental Pollution

Elimination of Hazardous Substances: Oil sludge contains large amounts of heavy metals, aromatic hydrocarbons, and other toxic and harmful substances. Leakage or improper handling can cause long-term, irreversible pollution to soil, groundwater, and the atmosphere. Pyrolysis, under high temperature and anaerobic conditions, can decompose oil sludge, converting it into carbon residue, pyrolysis oil, and combustible gases. Oil sludge treatment pyrolysis technology can effectively prevent the migration of harmful substances into soil and groundwater, improving soil and groundwater pollution caused by oil sludge accumulation and leakage.

2. Achieving Resource Optimization and a Circular Economy

Efficient Recovery of Valuable Resources: Through pyrolysis, we can efficiently recover various high-value byproducts from waste oil sludge. This not only helps reduce the overexploitation of primary resources (such as oil and natural gas) but also helps reduce the environmental footprint of primary resource extraction and processing, and provides a sustainable fuel source for downstream industries.

Reduced Carbon Footprint: Oil sludge slowly decomposes in the natural environment, releasing potent greenhouse gases such as methane (CH₄). Recovering oil sludge through pyrolysis technology avoids direct methane emissions, making a positive contribution to mitigating climate change. The pyrolysis oil and syngas produced during the pyrolysis process can serve as valuable energy sources, providing the necessary heat for the pyrolysis unit itself. This significantly reduces dependence on external fuels, thereby lowering energy consumption and carbon emissions throughout the production process.

1. High-Value Products

DOING's pyrolysis process typically yields three main commercially viable products from oil sludge:

Pyrolysis Oil

Yield: 40-50% (depending on sludge composition)

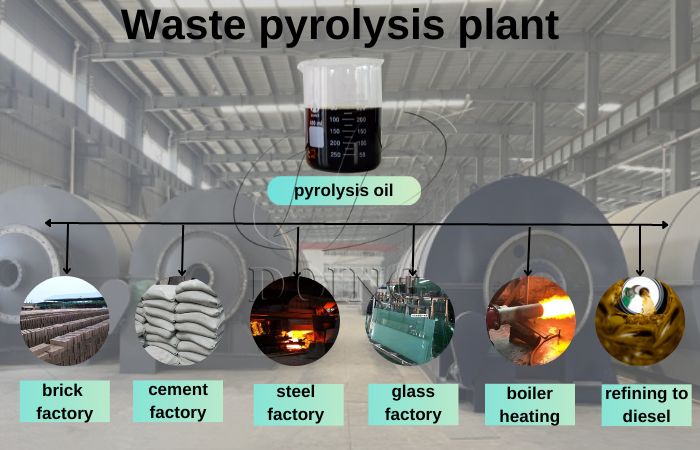

Value: This is the primary source of revenue. Pyrolysis oil can be used directly as heavy fuel oil, widely applied in industrial boilers, furnaces, and kilns. Through further refining and purification, it can be upgraded into feedstock for higher-value diesel or other petrochemical products, bringing higher added value to the company.

Applications of oil sludge pyrolysis oil

Syngas

Yield: Approximately 10% (depending on sludge composition)

Value: This combustible gas mixture, containing methane (CH₄) and carbon monoxide (CO), is primarily used for self-sufficiency within the plant, providing the necessary heat for the pyrolysis reactor. This significantly reduces the external energy costs of the pyrolysis plant.

DOING oil sludge treatment pyrolysis plant syngas recycling system

Soild Residue

Yield: 20-40% (depending on sludge composition)

Value: The solid byproduct is not entirely waste. After recovering hydrocarbons, this residue, primarily composed of inert minerals, can be reused as a building material additive, brick-making raw material, or asphalt filler. When it meets specific environmental standards, it can be safely landfilled as non-hazardous waste, thus avoiding high hazardous waste disposal costs.

2. Reduced Operating Costs

Avoid High Disposal Costs: By processing sludge themselves, companies can avoid the increasingly high and strictly regulated costs of third-party sludge disposal.

Energy self-sufficiency and reduced energy costs: As mentioned earlier, syngas and some pyrolysis oil can be used for the plant's energy supply, significantly reducing dependence on expensive external energy sources.

Reduce compliance risks and penalties: Adopting compliant and advanced pyrolysis technology effectively avoids environmental regulatory risks, hefty fines, and reputational damage that may result from improper treatment of oil sludge.

1. High oil recovery rate:

Uniform heating and thorough pyrolysis: Our pyrolysis reactor ensures uniform heating of the material, avoiding localized overheating that could lead to secondary pyrolysis of oil and gas into non-condensable gases, thus "squeezing out" every drop of recoverable oil.

Maximize oil yield: This means you can obtain more high-value pyrolysis oil from the same amount of oil sludge, improving your return on investment.

2. Advanced safety and emission control:

Fully sealed system: From feed to sludge discharge, the entire process is carried out under negative pressure and in a closed environment, eliminating the leakage of harmful gases and materials, ensuring the safety of production personnel and the plant environment.

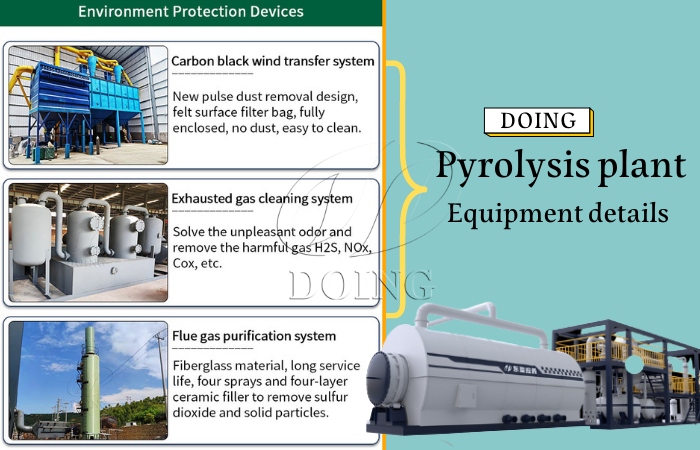

Exhaust Gas Purification System: Our integrated exhaust gas treatment system (including spray towers, ceramic filters, desulfurization towers, activated carbon adsorption, etc.) efficiently removes pollutants such as acidic gases, dust, and dioxins, ensuring emissions meet environmental standards.

DOING oil sludge treatment pyrolysis plant environment protection devices

3. Energy-Saving Design:

Energy Self-Sufficiency: During normal operation, the combustible syngas generated during the process is recovered and purified, then directly reused as fuel for heating the pyrolysis reactor, significantly reducing the consumption of external fuels (such as natural gas or coal).

4. Durability and Automation:

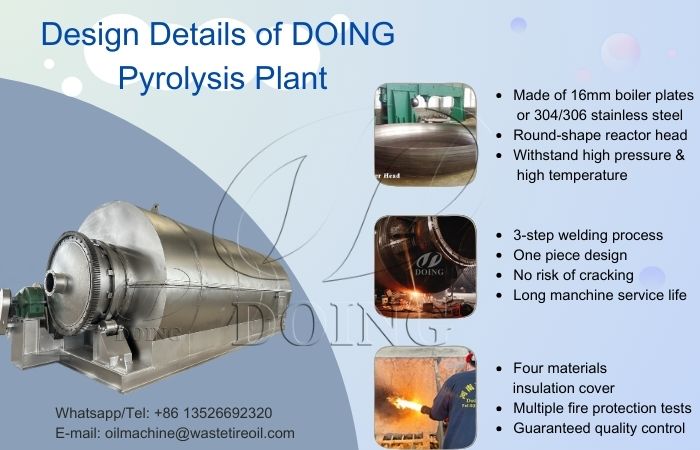

High Standards for Core Components: Core components such as the reactor are made of high-temperature resistant and corrosion-resistant steel, ensuring long-term stable operation in harsh chemical environments and minimizing maintenance needs and downtime.

Design details of DOING oil sludge treatment pyrolysis plant

High Automation: We provide fully automated feeding, sludge discharge, and PLC systems. This significantly reduces labor intensity and labor costs (typically only 1-2 people are needed to monitor the entire process).

DOING oil sludge treatment pyrolysis plant PLC system

In short, sludge pyrolysis represents a shift from simple "waste treatment" to intelligent "resource recovery." It successfully decouples economic activity from environmental degradation and aligns with the principles of a circular economy, delivering undeniable dual benefits: it creates environmental benefits by disposing of hazardous waste and protecting natural resources, while simultaneously generating profits by producing marketable products and reducing costs.

DOING oil sludge treatment pyrolysis plant manufacturer

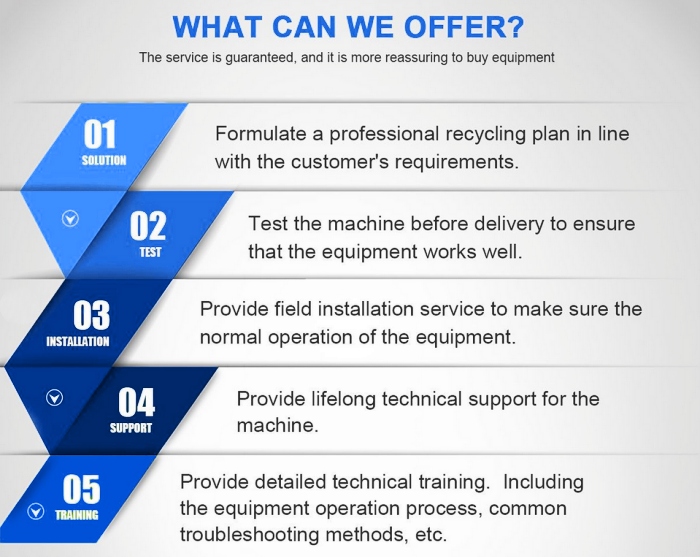

As a pyrolysis plant manufacturer with over 14 years of experience, DOING is committed to providing its customers with advanced waste oil sludge treatment pyrolysis plants and comprehensive customized services. If you are interested in the pyrolysis of sludge, please contact us.