Tel/WhatsApp

Tel/WhatsApp

China DOING Group offers a full range of high-quality waste pyrolysis machines for sale to meet various customer requirements. Our pyrolysis machine is widely suitable for processing various solid waste materials, including old tires, scrap plastic, waste rubber, oil sludge, coal tar, waste aluminum plastic, e-waste, and more. This makes it an ideal solution for solid waste management and treatment.

Waste pyrolysis machine for sale

Waste pyrolysis machine for sale

As an emerging waste recycling solution, pyrolysis waste management presents profitable business opportunities. This is evidenced by our export of pyrolysis machines to over 100 countries and regions worldwide. We are committed to delivering high-quality pyrolysis machines and services, and we look forward to the opportunity to serve you. Please feel free to contact us and send us your inquiry!

As one of the leading pyrolysis machine manufacturers in China, DOING Group has developed several popular models of waste pyrolysis machines for sale, including batch pyrolysis machines, semi-continuous pyrolysis machines, and fully continuous pyrolysis machines. These machines offer daily capacities ranging from 100kg to 50 tons per set.

| Pyrolysis Machine Type | Processing Capacity | Features |

| Batch pyrolysis machine for sale | 100KG-20Ton per day/set | Hot sale pyrolysis products, suitable for most of the investors for its high efficiency and favorable prices |

| Semi-continuous pyrolysis machine for sale | 10-20Ton per day/set | Cost-effective choice for investors who want higher automation degree middle scale pyrolysis machine |

| Fully continuous pyrolysis machine for sale | 15-50Ton per day/set | High automation degree, PLC intelligent control, 24/7 hours running, suitable for big industrial waste recycling business investors |

The cost of the pyrolysis machine is a primary concern for investors. We would like to provide a brief cost analysis of setting up a waste pyrolysis machine based on successful cases and market research. Several aspects should be considered, including the pyrolysis machine cost, pyrolysis plant land cost and construction cost, operating cost, installation and maintenance cost, and more.

(1) Pyrolysis Machine Price

The price of the pyrolysis machine itself constitutes a significant portion of the overall pyrolysis plant cost. The price varies depending on the working methods and capacity. Generally, higher automation levels or capacities result in higher prices. Among DOING products, the 100/500kg small skid-mounted/modular design pyrolysis plant is the most cost-effective model, making it suitable for small-scale investors with limited budgets and raw materials. For medium or large-scale pyrolysis machines for sale, our sales managers can customize a purchasing scheme tailored to your specific requirements.

Batch/Continuous China Doing pyrolysis machine for sale

Batch/Continuous China Doing pyrolysis machine for sale

In addition to the pyrolysis machine, the price will also depend on other auxiliary equipment, such as tire crushers, dryers, dedusting systems, etc. We will customize the pyrolysis system according to your needs.

(2) Pyrolysis Plant Land & Construction Cost

When planning to establish a pyrolysis plant, it is essential to find a suitable site. To minimize costs, it is advisable to choose a remote area with convenient access. Additionally, construction works, such as building the stove, wastewater pool, etc., will be necessary. Our engineers will design the plant layout based on your specific conditions to optimize space utilization.

China DOING pyrolysis machine installation site

China DOING pyrolysis machine installation site

(3) Pyrolysis Machine Operating Cost

Operating a pyrolysis machine requires fuel and labor. Our pyrolysis machine plant can utilize various fuels for heating the pyrolysis reactor, including oil, LPG, natural gas, charcoal, or coal. Furthermore, DOING waste pyrolysis machines are almost self-sufficient, utilizing combustible gas or pyrolysis oil produced during the process, thereby reducing fuel costs.

Labor input constitutes another part of the operating cost. In general, the waste tire plastic pyrolysis oil plant is easy and safe to operate, with several workers able to run the entire plant smoothly, especially when using fully continuous pyrolysis machines.

(4) Installation & Maintenance Cost

When considering a waste pyrolysis machine for sale, it is essential to consider after-sales service. Typically, our engineers will be on-site to assist with installation and commissioning once basic construction work is completed. Our plants have a normal operational lifespan of 5 to 8 years. During this period, we provide after-sales tracking service, regular visits, product updating service, and more. Additionally, our pyrolysis machines come with a one-year free warranty. Should you have any questions, please do not hesitate to contact us at any time.

Manufacturer services of pyrolysis machine for sale

Manufacturer services of pyrolysis machine for sale

While the initial cost of the pyrolysis machine may be significant, waste pyrolysis plants are gaining popularity among investors. In recent years, China DOING Group has assisted over hundreds of customers with their pyrolysis oil plants across the globe, including in Indonesia, Canada, Romania, India, Mexico, the United States, Panama, Vietnam, Thailand, the UK, South Africa, Nigeria, Colombia, Brazil, and more. This is due to the profitability and promising nature of establishing a pyrolysis plant.

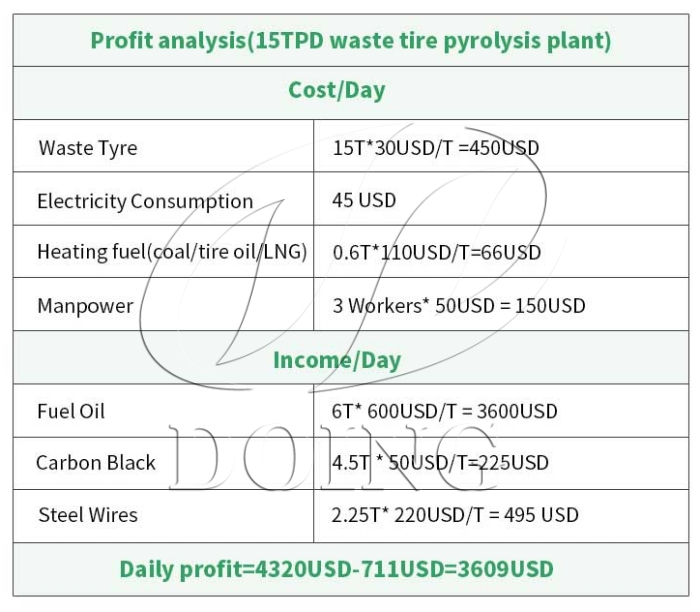

As an emerging technology, pyrolysis is supported by governments for its eco-friendly design and significant impact. Statistics show that only a small portion of waste is currently recycled, with the majority being disposed of in landfills or discarded. However, the pyrolysis process enables virtually all waste, including non-degradable waste, to be fully recycled into fuel oil and carbon black. Clearly, pyrolysis technology offers substantial environmental benefits while turning waste into wealth. Here we listed a profit analysis of 15TPD waste tyre pyrolysis machine for sale for your reference:

Waste tire pyrolysis machine profit analysis

Waste tire pyrolysis machine profit analysis

In conclusion, our waste pyrolysis machine is multifunctional and widely suitable for processing scrap tires, plastic waste, waste rubber, oil sludge, and more. With abundant and affordable raw materials, it boasts a wide range of applications, making investing in a waste pyrolysis machine a lucrative opportunity. It has been proven that the waste pyrolysis machine presents a very promising business opportunity, yielding various end products such as fuel oil and carbon black that generate substantial profits.

Pyrolysis machine final products applications

Pyrolysis machine final products applications

Choosing China DOING means gaining access to top-quality waste pyrolysis machines for sale, along with a customized business plan tailored to your specific conditions. Furthermore, you will benefit from our comprehensive service, from initial consultation to after-sales tracking. Contact us now to arrange a visit to our pyrolysis plant manufacturing factory!