Tel/WhatsApp

Tel/WhatsApp

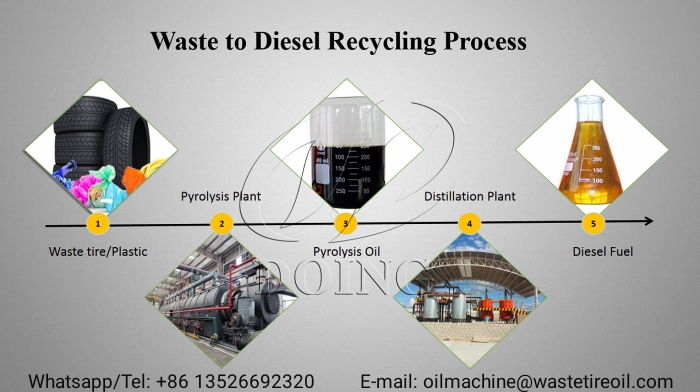

Congratulations! Another waste tire plastic to diesel recycling project was installed with the help of Henan Doing Company. The installation location for this project is in Fiji. On the one hand, it can achieve environmentally friendly treatment of waste tire and plastic scrap, and the operation of the equipment meets Fiji's strict environmental protection indicators. On the other hand, it realizes the transformation of waste into resources and can create better revenue.

Waste tire plastic to diesel recycling project picture

Waste tire plastic to diesel recycling project picture

In 2023, a waste recycling company in Fiji approached Doing, seeking an efficient solution to handle a large volume of waste tires and plastic scraps. The client aimed not only to address environmental concerns through eco-friendly disposal methods but also to generate additional revenue streams from the waste treatment.

Consultation and Planning (2023): Doing engaged in detailed discussions with the client to understand their specific needs, waste composition, and desired output. Our technical team analyzed the characteristics of the waste materials and began designing a customized solution that would maximize efficiency and meet environmental standards.

Site Visit and Finalization (2024): The client visited DOING's fully continuous pyrolysis plant (the newest pyrolysis technology) in China to check the equipment capabilities and discuss the proposed solution. Based on feedback and further requirements gathered during the visit, the project plan was finalized, focusing on waste pyrolysis and oil refining processes tailored to the client's detailed situation.

Equipment Configuration

-2 x 10-ton Pyrolysis Plants: These plants are specifically designed to process waste tires and different types of plastic scraps. The pyrolysis process converts these materials into valuable products such as fuel oil, carbon black, and combustible gases (namely syn-gas). Recognizing the complexity of the waste materials, particularly plastic scrap that may cause wax buildup during processing, DOING incorporated special anti-waxing devices in the pyrolysis plant.

Waste tire plastic to diesel oil pyrolysis refining process

Waste tire plastic to diesel oil pyrolysis refining process

- 1 x 10-ton Waste Oil Refining Machine: This machine further processes the pyrolysis oil to refine it into higher-quality diesel fuel products, enhancing its market value and applicability. The diesel fuel is a non-standard diesel, which can be used in trucks, diesel generators, ships, boats, heavy machinery, etc.

Both the tire plastic pyrolysis plants and the waste oil refining machine are equipped with advanced environmental protection devices. These systems effectively manage emissions and waste by-products, ensuring the entire process meets Fiji's stringent environmental regulations.

Installation and Commissioning (2025): DOING's professional installation team traveled to Fiji to oversee the setup of the equipment. They ensured every component was correctly installed and conducted rigorous testing to guarantee smooth operations. Training sessions were also held for the client's staff to familiarize them with the equipment's operation and maintenance.

Tire plastic pyrolysis refining to diesel plant in Fiji

Tire plastic pyrolysis refining to diesel plant in Fiji

This successful waste tire plastic to diesel recycling project installed in Fiji is another recognition of DOING's capabilities in providing customized waste recycling solutions. We will continue to leverage the technical expertise and industry experience to deliver more efficient and sustainable waste pyrolysis and waste oil refining solutions to clients worldwide.