Tel/WhatsApp

Tel/WhatsApp

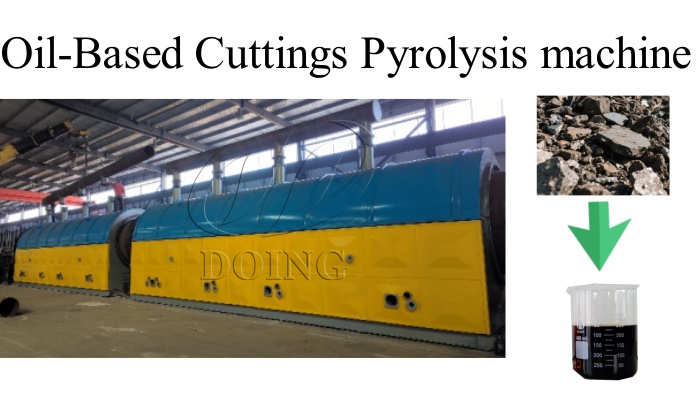

This video shoes the successful installation and commissioning of an industrial continuous oil-based drill cuttings(OBDC) pyrolysis treatment plant, independently developed and manufactured by DOING Group. This OBDC oil sludge pyrolysis project, now officially operational in Shandong Province of China, marks a pivotal expansion of our intelligent continuous pyrolysis technology's application spectrum, building upon our expertise in processing waste tires, plastics, and oily sludge.

Oil based drilling sludge treatment pyrolysis machine

Oil based drilling sludge treatment pyrolysis machine

The Challenge: Eco-friendly Oil-Based Drill Cuttings Treatment

Oil-based drill cuttings (OBDC) are a persistent byproduct of oil and gas exploration and production. Traditionally, their disposal presents significant environmental and operational challenges due to their high organic content and potential for hazardous contamination. Improper handling can lead to soil and water pollution, while conventional treatment methods often fall short in terms of efficiency and environmental compliance.

Our Solution: Advanced Continuous Pyrolysis Technology

Our industrial continuous pyrolysis plant provides a superior solution for OBDC. The process involves high-temperature pyrolysis, where the organic macromolecules within the oil-based drill cuttings are broken down into smaller molecules and monomers. This sophisticated thermochemical transformation yields valuable by-products:

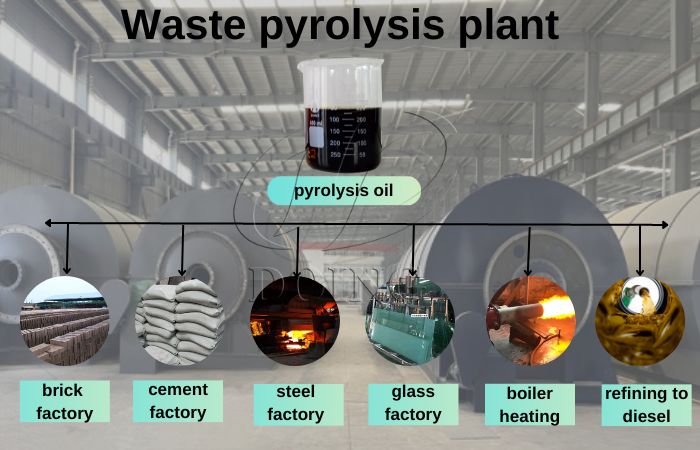

Pyrolysis Oil: A high-quality fuel oil, which can be effectively recovered and reused, creating a valuable energy resource. It can be used as a substitute alternative fuel for various industrial heating uses. For wider applications, you can use pyrolysis oil distillation plant to refine reclaimed fuel oil from oil-based drill cutting pyrolysis process for diesel extraction.

OBDC pyrolysis reclaimed fuel applications

OBDC pyrolysis reclaimed fuel applications

Regenerated Sludge/Soil: The treated residue, or sludge, boasts a remarkably low residual oil content, often below 0.3%. This makes it suitable for safe, harmless landfilling or, more importantly, for reuse in construction materials, road building, and as concrete fillers. This closed-loop approach ensures a complete chemical cycle for oil-based drill cuttings, maximizing resource utilization and minimizing waste.

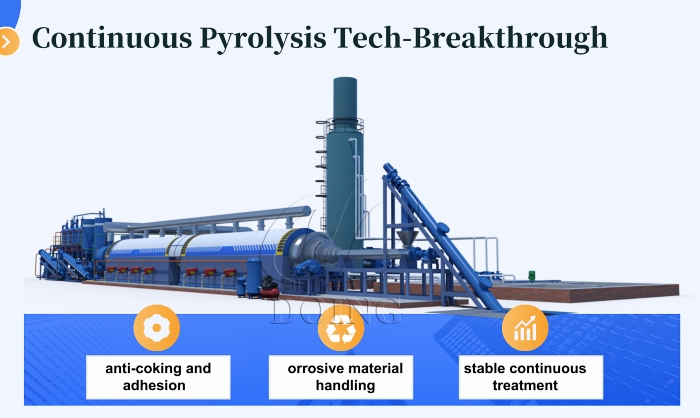

Overcoming Industry Challenges: A New Benchmark in Oily Waste Treatment

This continuous OBDC pyrolysis plant running project represents a significant technological breakthrough, addressing and overcoming critical challenges inherent in oil-based drill cuttings pyrolysis. Key pain points such as coking and adhesion within the reactor, severe corrosion due to aggressive substances, and the inherent difficulties in achieving stable continuous production have been meticulously conquered. Our newly developed solutions offers a practical solution for the harmless, efficient and industrial treatment of oil-based drill cuttings.

Continuous oil sludge pyrolysis plant technology advancement

Continuous oil sludge pyrolysis plant technology advancement

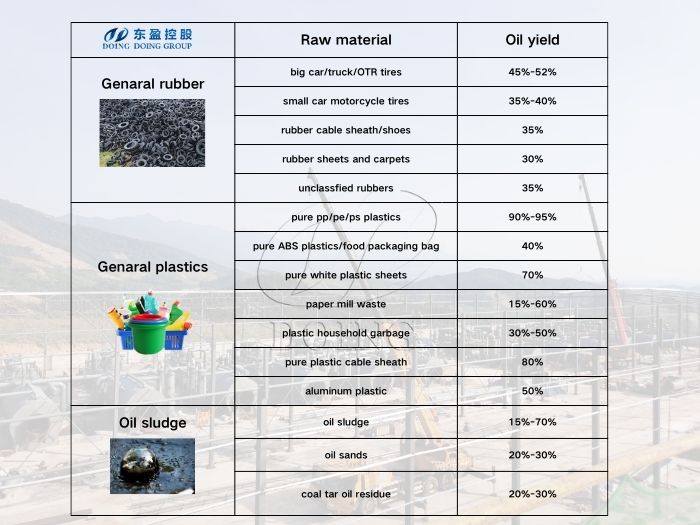

Versatile Applications Beyond Drill Cuttings

The advanced continuous pyrolysis plant developed by DOING Group is not limited to oil-based drill cuttings. Its robust design and adaptable technology make it highly effective for a wide range of oily waste streams, including: Landing Oil Sludge, Refinery Oil Sludge, Tank Bottom Sludge, Ground Oil Spills, Mazut, Rubber Powder, Waste Tires, Waste Plastics, etc.

Continuous pyrolysis plant feedstocks and oil yields

Continuous pyrolysis plant feedstocks and oil yields

DOING Group is a leading manufacturer and supplier of pyrolysis plant in the innovative waste to fuel energy recovery sector. Our fully continuous pyrolysis technology is deployed across multiple project sites as an efficient, compliant, environmentally friendly, and automated industrial-scale waste treatment solution. Contact us for more information about our equipment and to view videos showcasing our pyrolysis projects in operation.