Tel/WhatsApp

Tel/WhatsApp

Tire recycling encompasses various technologies and processes designed to transform waste tires into valuable materials or energy. Below are some of the primary technology:Waste ti...

Plastic bottles are common plastic waste. Many customers are curious whether pyrolysis technology can be used to "turn waste into treasure---fuel oil" by pyrolysis machine? In fact...

Oil-based rock cuttings(OBDC) thermal desorption unit, also called oil sludge TDU thermal pyrolysis machine, is a kind of oil sludge recovery and treatment device that separates oi...

The waste tire pyrolysis machine is not just a simple machine, it has many configuration parts. There are many customized options for waste tire pyrolysis machines, depending on th...

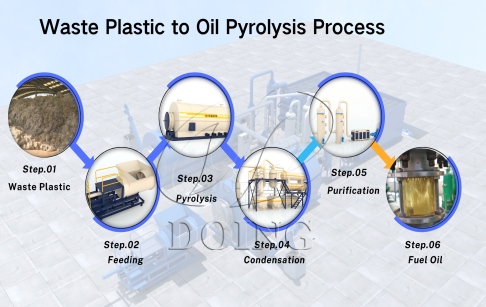

The process flow of DOING plastic pyrolysis oil production line mainly includes feeding, heating, dewaxing, cooling, recycling of tail gas, carbon black slag discharge and other st...

A waste oil treatment plant, particularly one using distillation technology, can yield several valuable products through the treatment process of waste oil. Here are three main pro...

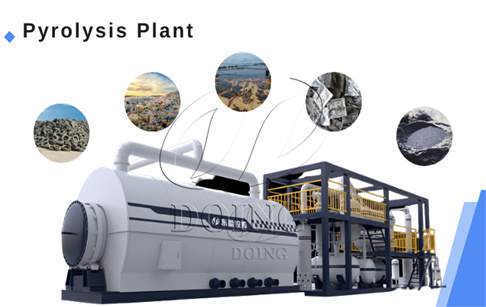

A solid waste pyrolysis plant can convert various types of solid waste like waste rubber tires, plastic, oil sludge, coal tar, aluminum plastic, wood wastes, metal plastic wastes, ...

Tire pyrolysis is a process that involves the decomposition of used tires like car tyres, rubber tyres, rubber materials, OTR, bicycle tyres, etc. into valuable products such as py...

As a polymer organic compound, waste tyres are broken down into small molecules when heated in an anaerobic environment. After cooling, these small molecules recombine to form liqu...