Tel/WhatsApp

Tel/WhatsApp

Plastic bottles are common plastic waste. Many customers are curious whether pyrolysis technology can be used to "turn waste into treasure---fuel oil" by pyrolysis machine? In fact, this is closely related to the material of the plastic bottles.

Waste plastic bottles for recycling uses

Waste plastic bottles for recycling uses

Most of the common plastic bottles and mineral water bottles are made of polyvinyl chloride (PVC) or polyethylene terephthalate (PET). These plastic bottles and mineral water bottles cannot be turned into fuel by pyrolysis machine.

PVC material made plastic bottles are not suitable for pyrolysis into oil because PVC releases a large amount of hydrogen chloride (HCl) gas during high-temperature pyrolysis. This gas is not only highly corrosive, but also can seriously damage oil refining equipment, shorten the service life of equipment, and increase maintenance costs; at the same time, untreated hydrogen chloride gas is discharged into the atmosphere, which will form acid rain and cause great damage to the environment. In addition, the oil products produced by PVC pyrolysis will also contain chlorine, resulting in poor oil quality and difficulty in meeting industrial use standards.

PET material made plastic bottles are also not suitable for oil refining. PET has a stable structure. It is difficult to completely crack and convert it into oil products at the conventional plastic pyrolysis process temperature. Even if it can be cracked, the yield of the obtained oil products is low, the quality is unstable, and a large amount of difficult-to-handle residues will be produced. From the economic and technical point of view, it is not feasible.

Different materials of plastic bottles for pyrolysis

Different materials of plastic bottles for pyrolysis

However, the plastic bottles made of polypropylene (PP) and polyethylene (PE) are ideal processing materials for pyrolysis machines. PP materials are commonly found in plastic barrels, plastic basins, and some food packaging bags. It has a high carbon-to-hydrogen ratio and can be efficiently converted into fuel oil during the pyrolysis process. The oil products produced are of good quality and have few impurities. They can be widely used in industrial heating, power generation and other fields. PE materials are more widely used, such as plastic wrap, plastic bags, plastic films, etc. The PE molecular chain structure is relatively simple and easy to crack under high temperature conditions. The pyrolysis products are mainly fuel oils, carbon black and syn-gas. At the same time, there are few by-products, and the pyrolysis process is stable, which is convenient for industrial production.

Therefore, not all plastic bottles and mineral water bottles can be turned into oil by pyrolysis machine. Choosing the right plastic raw materials is the key to achieving a win-win situation in the economic and environmental benefits of plastic pyrolysis.

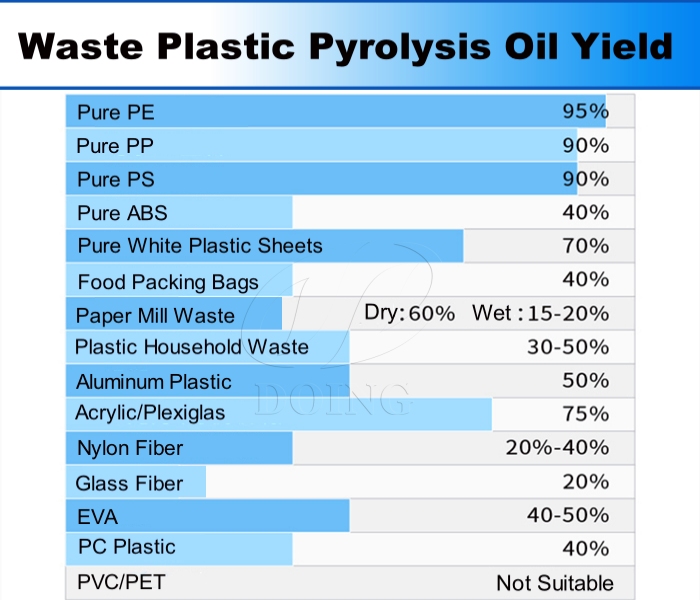

Here Henan Doing Company listed suitable scrap plastic materials for pyrolysis machine: thermoplastics such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP) and polystyrene (PS), etc. These plastics can produce higher-quality fuel oil products during the plastic to fuel pyrolysis process due to their stable chemical structure. Generally speaking, basically, the conventional plastic products we see in daily life, such as plastic bags, plastic films, woven bags, agricultural mulch films, paper mill scraps, domestic garbage, etc., can be used for pyrolysis. In addition, there are some unconventional plastics, such as polyurethane (PU), polycarbonate (PC), ethylene-vinyl acetate copolymer (EVA), melamine (MF), acrylic, nylon fiber, glass fiber and other unconventional waste plastic products can also be turned into fuel oil by pyrolysis machines.

Waste plastic recycling pyrolysis oil yields

Waste plastic recycling pyrolysis oil yields

If you have any questions about the selection of plastic pyrolysis raw materials and equipment selection, please feel free to contact us. We will provide you with professional and comprehensive services.

Waste plastic pyrolysis machine manufactured by DOING

Waste plastic pyrolysis machine manufactured by DOING

The pyrolysis machines produced by Henan Doing Company have been deeply optimized for plastic raw materials and includes wax removal device. The equipment adopts advanced pyrolysis technology and intelligent temperature control system, which can accurately control the pyrolysis temperature and reaction time to maximize the raw material conversion rate and oil yield. At the same time, it is equipped with an efficient environmental protection treatment device, which can harmlessly treat the waste gas and waste residue generated during the plastic pyrolysis process to ensure the green and environmentally friendly production process. Whether it is a small enterprise dealing with daily plastic waste or a large recycling enterprise carrying out large-scale production, our waste plastic pyrolysis machines can provide stable, efficient and environmentally friendly solutions.