Tel/WhatsApp

Tel/WhatsApp

Tire recycling encompasses various technologies and processes designed to transform waste tires into valuable materials or energy. Below are some of the primary technology:

Waste tire recycling technology

This is the most common technology involving the shredding of tires into smaller pieces, known as tire-derived aggregate (TDA) or crumb rubber. These materials find applications in road construction, playground surfaces, athletic tracks, and more. Mechanical recycling technology is relatively mature and straightforward to implement. But relatively speaking, the investment in the entire equipment production line will be relatively large. In addition, its limitations include: The application scope of the products is relatively limited, often requiring further processing to enhance their value.

Waste tires are incinerated to generate heat and electricity. This method offers high energy utilization efficiency but has several drawbacks: The incineration process generates harmful gases such as sulfur dioxide and nitrogen oxides, posing significant environmental pollution risks. After incineration, a large amount of ash residue remains, requiring further treatment.

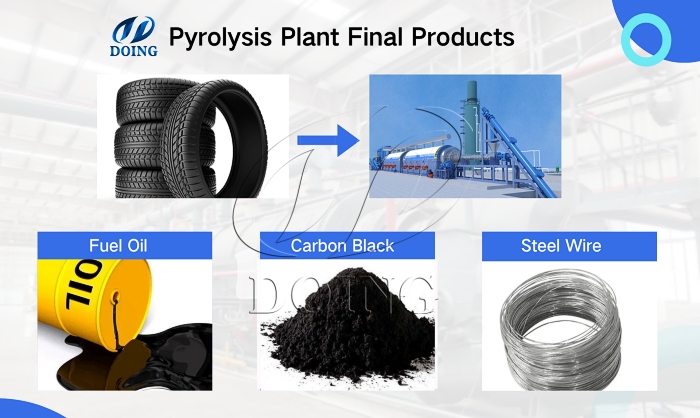

Pyrolysis is a thermal decomposition process that breaks down tires in an oxygen-free environment at high temperatures. The result is a mixture of gases, fuel oil, carbon black, and steel wire, all of which can be reused. Below is a detailed comparison of pyrolysis with other technologies:

Comparison with Mechanical Recycling

Tire recycling pyrolysis equipment offers higher added value for recycling. It can convert waste tires into fuel oil, carbon black, and other marketable products, whereas mechanical recycling products often have limited economic value.

Pyrolysis achieves more thorough material recovery, effectively separating and recycling various components of tires. In contrast, mechanical recycling may leave residual materials.

Waste tire recycling pyrolysis products

Comparison with Incineration

Pyrolysis produces fewer pollutants. Unlike incineration, it avoids the direct emission of harmful gases like sulfur dioxide. Through proper treatment, pyrolysis can minimize environmental impact.

Pyrolysis provides more flexible product applications. The fuel oil and carbon black generated can be used in multiple industries, while energy recovery primarily focuses on heat and electricity generation.

Usages of waste tire pyrolysis products

Pyrolysis technology itself is also constantly developing. For example, DOING's pyrolysis euipment can efficiently recycle tires, convert them into valuable resources and minimize pollution. The environmentally friendly design of DOING's pyrolysis equipment is reflected in the following four aspects:

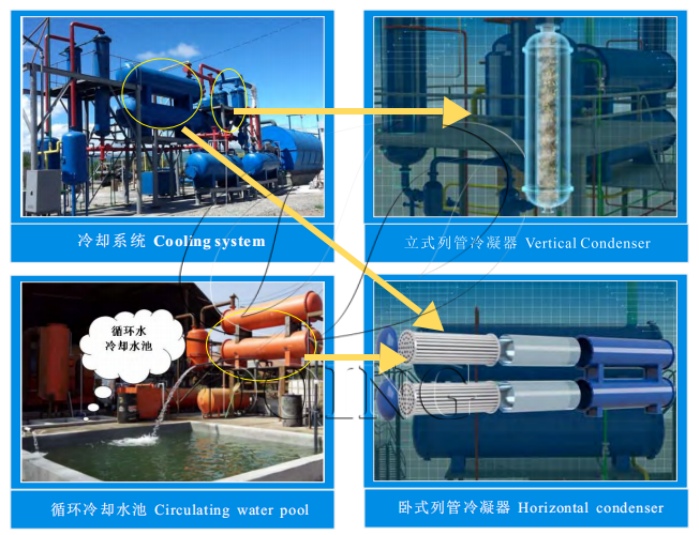

Circulating Cooling Water System

All cooling water used in the system is recycled, eliminating wastewater discharge and preventing pollution. Regular water replenishment is needed to compensate for evaporation losses, without the need for replacement or wastewater discharge.

DOING waste tire pyrolysis equipment circulating cooling water system

Carbon Black Discharge System

The system employs a side-discharge mechanism, allowing carbon black to be directly discharged underground, preventing it from escaping into the factory environment. A sealed screw conveyor then lifts the carbon black to the ground. Additionally, a steel wire extraction machine is used to remove steel wire from the reactor, with the entire process being fully sealed to avoid carbon black dispersion.

DOING waste tire recycling pyrolysis equipment carbon black discharge system

Odor Removal and Flue Gas Purification Systems

When processing waste tires, pyrolysis produces hydrogen sulfide (H₂S), which has a rotten egg smell and is a polluting gas. Mixed with tail gases, it can create an unpleasant odor. DOING’s odor removal system effectively eliminates H₂S. After purification, most of the tail gas is recycled to heat the reactor, minimizing emissions. The flue gas purification system removes harmful gases, primarily sulfides, using catalysts, water spray devices, exhaust gas deodorization systems, and flue gas purification systems. All spray devices utilize circulating water.

DOING waste tire pyrolysis equipment gas purification system

In summary, tire recycling technologies include mechanical recycling, energy recovery, and pyrolysis. Each method has its advantages and disadvantages. Waste tire recycling pyrolysis technology, particularly continuous tire pyrolysis equipment, stands out due to its high recycling value, thorough material recovery, and environmental protection. It represents a promising direction for tire recycling. If you are planning to engage in tire pyrolysis recycling business, welcome to contact us.