Tel/WhatsApp

Tel/WhatsApp

On May 30, 2025, a fully continuous tire rubber powder pyrolysis plant developed and manufactured by DOING, including a continuous feeding system, a continuous pyrolysis system, and a continuous condensation system, was being installed at a tire rubber powder pyrolysis project site in Shandong Province. All installation processes are expected to be completed soon, and the project will enter the trial production phase. This is the installation site:

DOING continuous tire rubber powder pyrolysis plant in China

DOING continuous tire rubber powder pyrolysis plant in China

DOING continuous tire rubber powder pyrolysis plant in China

DOING continuous tire rubber powder pyrolysis plant in China

The client is engaged in foreign trade and has two tire shredding plants located overseas. Given the current high domestic scrap tire recycling prices and weak profit margins, he considered importing shredded tire rubber powder into China and investing in a tire rubber powder pyrolysis plant to generate high returns. They searched online for a reliable tire rubber powder pyrolysis plant supplier and sent us an inquiry.

Taking into account the client's raw material conditions, local environmental standards, and industrial policies, DOING sales manager recommended a 50-ton/day fully continuous pyrolysis plant. This process met their requirements in terms of equipment efficiency, continuous production capacity, pollution control, and environmental performance. The client was very satisfied and entered into a partnership with us. On April 12, 2025, a 50-ton fully continuous tire rubber powder pyrolysis plant produced by DOING was ready for loading and shipment to a customer project site. Below are photos of the shipment, taken at the DOING factory:

DOING continuous tire rubber powder pyrolysis plant shipped to China

DOING continuous tire rubber powder pyrolysis plant shipped to China

To meet national environmental standards for waste tire processing and market demand for high-efficiency, environmentally friendly, and energy-saving pyrolysis plants, DOING upgraded its tire pyrolysis production line to feature continuous feeding, continuous pyrolysis, and continuous slag discharge, all within a fully enclosed environment.The continuous tire rubber powder pyrolysis plant utilizes a continuous feeding, pyrolysis, and oil discharge design. Once started, it can operate for 45-60 days, offering high continuous production capacity. This solves the problems of batch type pyrolysis plant, which often requires frequent heating to heat a cold furnace, resulting in low production efficiency, heat waste, and low exhaust gas recycling efficiency.

DOING continuous tire rubber powder pyrolysis plant advantages

DOING continuous tire rubber powder pyrolysis plant advantages

The continuous tire rubber powder pyrolysis plant inlet and outlet, material pyrolysis and gasification, oil and gas collection, and solid product transportation are all completed within enclosed equipment and pipelines, preventing oil and gas leaks. Its closed operation further enhances environmental performance, eliminating carbon black dust pollution. A supporting environmental treatment system ensures that waste generated during the tire rubber powder pyrolysis process undergoes specialized desulfurization, denitrification, and dust removal treatments, ensuring environmentally friendly discharge and minimizing pollution.

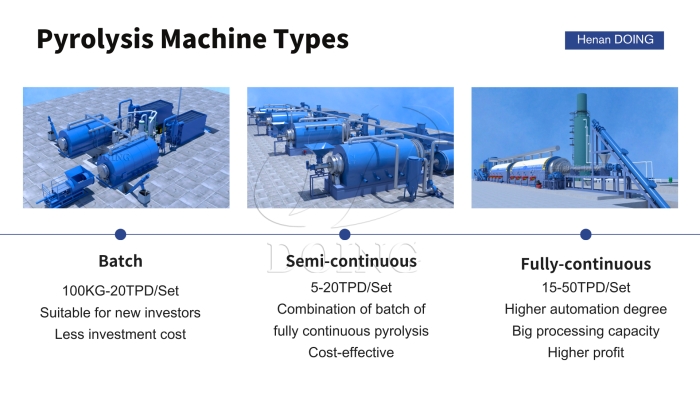

DOING waste to fuel pyrolysis plant types

DOING waste to fuel pyrolysis plant types

As a professional pyrolysis plant manufacturer in the field of waste pyrolysis treatment, DOING has long been committed to the research and development of intelligent recycling and processing equipment for waste tires, waste plastics, oily sludge, domestic waste, construction waste, and other materials. Our independently developed skid-mounted, batch, semi-continuous, and fully continuous product lines demonstrate outstanding performance in waste recycling treatment, particularly in the development and manufacture of fully continuous tire rubber powder pyrolysis plant. DOING also offers professional pre-sales services, including plant layout planning and on-site inspections. Please contact us for inquiries.