Tel/WhatsApp

Tel/WhatsApp

Oil-based rock cuttings(OBDC) thermal desorption unit, also called oil sludge TDU thermal pyrolysis machine, is a kind of oil sludge recovery and treatment device that separates oil and other organic matter in oil-based rock cuttings from solid matrix by heating. It uses high temperature environment to promote the volatilization or decomposition of oil and organic matter in oil-based rock cuttings, so as to achieve oil recovery and harmless treatment of solid waste.

Oil based rock cutting thermal desorption unit

Oil based rock cutting thermal desorption unit

The following is a detailed introduction of the relevant principles and technical characteristics of thermal desorption unit for oil-based rock cuttings.

The thermal desorption technology of oil-based rock cuttings(OBDC) is based on the principle of combining thermal decomposition and physical separation. Through precise temperature control and process optimization, it can achieve efficient separation of oil and slag. A whole OBDC thermal desorption unit usually includes key components such as pretreatment system, feeding system, thermal desorption reactor, oil and gas separation system, tail gas treatment system, flue gas treatment system, discharge system and control system. Its workflow is divided into four core stages:

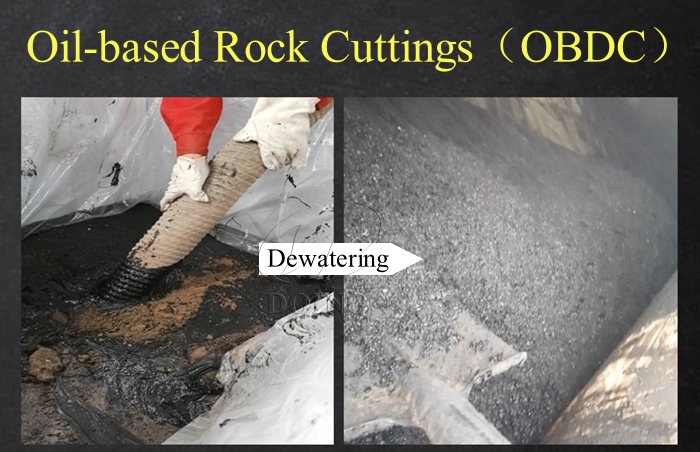

1. Pretreatment stage: The oil-based cuttings are first pretreated by crushing, screening, centrifuge dehydration, etc. to make their particle size uniform and the water content reduced to about 4%, ensuring the stability and efficiency of the subsequent thermal desorption process. The pretreated oil-based cuttings are fed by a spiral auger. The specially designed feeding system can adapt to complex working conditions with high viscosity and high impurities, improving the applicability of the equipment.

Oil-based rock cuttings OBDC pre-treatment dewatering process

Oil-based rock cuttings OBDC pre-treatment dewatering process

2. Thermal desorption stage: The oil-based cuttings(OBDC) enter the thermal desorption reactor and are heated to a certain temperature (usually 350-550℃) in an oxygen-free or micro-oxygen environment. The oil substances are volatilized by heat and separated from the solid particles. At the same time, the use of temperature-stage control technology (such as 100℃ low-temperature dehydration, 180-370℃ medium-temperature dehydration of light oil, and 520℃ high-temperature dehydration of heavy oil) can accurately match the characteristics of different oil products and maximize the recovery efficiency.

3. Oil and gas separation stage: The volatile oil and gas are quickly liquefied through a multi-stage condensation system, and the purity of the recovered oil has reached more than 95%, which can be directly reused in industrial processes. The non-condensable gas is purified and returned to the thermal desorption reaction furnace as fuel for heating and combustion.

Oil gas cooling system of thermal desorption unit

Oil gas cooling system of thermal desorption unit

4. Solid residue treatment: The oil content of the Solid residue after thermal desorption is ≤0.3%, which can be used as a resource for building materials, road construction materials, concrete fillers, etc., such as: the production of lightweight aggregates; or safe landfill.

1. High efficiency: The oil-based rock cuttings thermal desorption unit can efficiently separate the oil in the rock cuttings in a short time, and the oil content is reduced to less than 0.3%. The treatment efficiency is high, which greatly shortens the treatment cycle. Our equipment operation process is based on more than 20 years of equipment manufacturing and operation experience, and the oil-based rock cuttings thermal desorption technology is relatively mature. In addition, the material selection of the equipment is carefully selected in combination with waste oily sludge raw materials to ensure high-quality equipment manufacturing, more stable operation and durability.

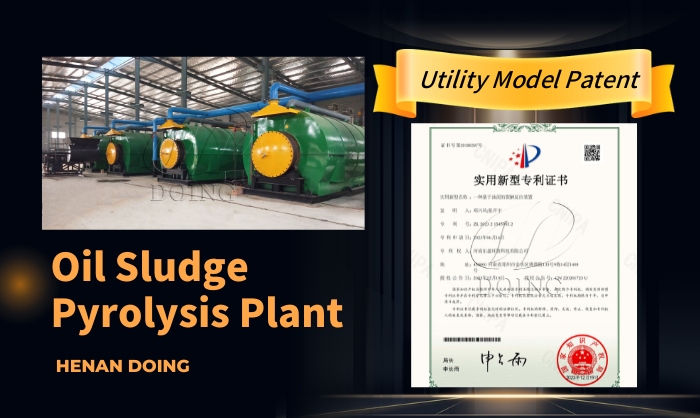

DOING oil sludge thermal desorption unit certificate

DOING oil sludge thermal desorption unit certificate

2. Environmental protection: The feeding system, discharge system and thermal desorption treatment system are all designed in a closed type to reduce the unorganized emission of VOCs and dust, and effectively prevent secondary pollution. By accurately controlling the heating temperature and time, the emission of harmful gases can be reduced. At the same time, the recovered oil can be used as a renewable resource after treatment, realizing the recycling of resources.

3. High degree of automation: The PLC automatic control system is adopted to monitor key parameters such as temperature, pressure, oxygen content in real time, and automatically warn of abnormal conditions and start the protection program. It can realize remote monitoring and intelligent adjustment of equipment, reducing the risk and cost of manual operation.

4. Strong adaptability: It can handle various types of oil-containing sludge such as oil-based cuttings, oil-contaminated waste, ground sludge, oil field waste oily sludge mud/pit, tank bottom sludge, ship oil sludge, etc. with different types and oil contents. It is applicable to materials with an oil content range of 15%-70%, and has wide applicability and compatibility.

Different types of thermal desorption units for sale

Different types of thermal desorption units for sale

Henan Doing's oil-based rock cuttings(OBDC) thermal desorption unit provides skid-mounted, batch, semi-continuous and continuous models for selection, suitable for oil fields, refineries, hazardous waste treatment centers and other scenarios. Investors who are interested in oil-based rock cuttings and waste sludge treatment and recycling are welcome to consult.