Tel/WhatsApp

Tel/WhatsApp

Are you looking for a reliable and efficient Rubber Process Oil (RPO) pyrolysis machine? Our company specializes in manufacturing high-quality pyrolysis machines designed to convert waste materials into valuable resources.

Whether you're in the recycling industry, a government agency, operators of factories that consume large amounts of fuel resourcesor a waste management company, DOING RPO pyrolysis machine offers a sustainable solution for waste treatment and resource recovery.

DOING Brand RPO rubber pyrolysis machine for sale

DOING Brand RPO rubber pyrolysis machine for sale

The RPO pyrolysis machine operates on the principle of thermal degradation in the absence of oxygen. The process involves heating waste rubber materials such as waste tires, rubber cable skins, rubber soles, conveyor belts, rubber pieces/powder, rubber shoes, rubber powder, etc. to high temperatures (typically between 250–500°C) in an inert environment. This causes the breakdown of complex polymer structures into simpler hydrocarbon components. The primary reactions include depolymerization, where long-chain hydrocarbons are broken down into shorter chains, resulting in the production of rubber process pyrolysis oil(RPO), syngas, and carbon black.

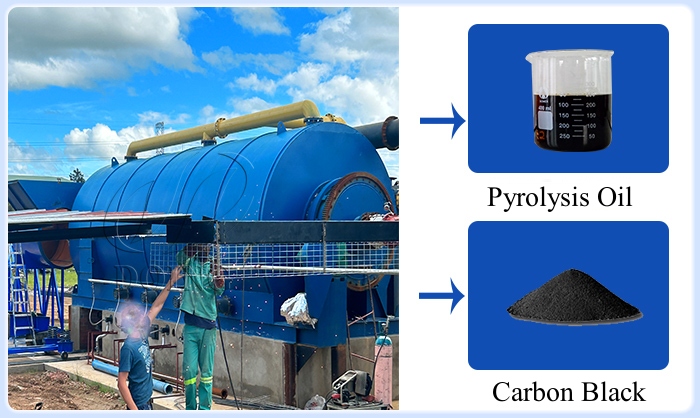

Rubber process RPO pyrolysis machine final products

Rubber process RPO pyrolysis machine final products

Raw Material Preparation: Waste materials are collected and preprocessed (shredded, crushed, etc.) to ensure uniformity and remove impurities. The waste rubber preprocess is needed only when you install the sem-continuous or fully continuous rubber pyrolysis machine.

Feeding System: The prepared raw rubber material is fed into the pyrolysis reactor through the feeding system and maintain an oxygen-free environment.

Pyrolysis Reaction: Inside the reactor, the waste rubber material undergoes thermal degradation, producing pyrolysis oil vapors, hydrocarbon gases, and carbon black.

Condensation and Separation: The pyrolysis vapors are cooled and condensed into liquid products. The gases are purified and can be reused as fuel for the reactor.

Product Collection: The resulting products—pyrolysis oil, carbon black, and residual gases—are collected and processed for further use or sale.

Rubber Pyrolysis Oil(RPO): Can be used as a liquid fuel in industrial burners of heavy industries, like or further refined into products like diesel.

Carbon Black: Used in various industrial applications, including tire manufacturing and as a pigment in inks and paints.

Syngas: Can be utilized as a fuel source for the pyrolysis process itself or sold as a valuable energy resource.

RPO rubber pyrolysis oil and carbon black applications

RPO rubber pyrolysis oil and carbon black applications

Investing in an RPO rubber process oil pyrolysis machine offers significant profit potential. The conversion of waste materials into marketable products reduces dependency on raw material imports, waste rubber materials treatment and management, and creates additional revenue streams. The pyrolysis oil can be sold directly or refined for higher-value applications, while carbon black and syngas provide additional income sources. Here are the sales price of rubber process pyrolysis products for your reference:

Rubber Process Pyrolysis Oil: 500USD/Ton

Carbon Black: 50-180USD/Ton

Additionally, the machine's energy-saving features and automated operation reduce operational costs, further enhancing profitability.

Our RPO pyrolysis machine is suitable for various regions, including countries like India, Vietnam, Indonesia, Germany, France, Russia, Brazil, Spain, Korea, Canada, United States of America, United Kingdom, South Africa and the Netherlands. It is ideal for investment by government recycling agencies, waste management companies, industrial enterprises, and environmental protection organizations looking to enhance their waste treatment capabilities and contribute to sustainable development.

Pyrolysis machine running sites installed by China Manufacturer Henan DOING

Pyrolysis machine running sites installed by China Manufacturer Henan DOING

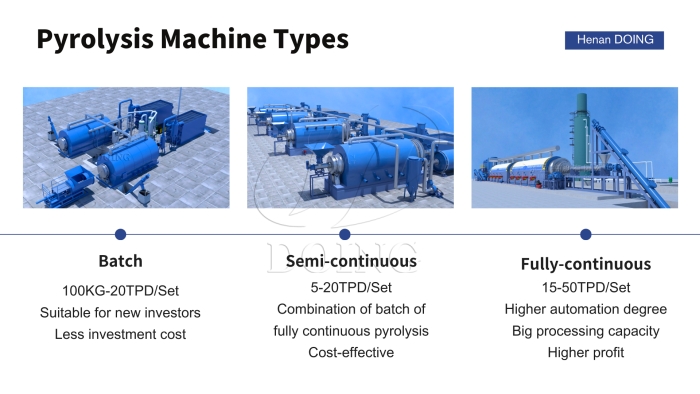

We offer RPO pyrolysis machines in different types and sizes to meet various production needs. Our batch-type machines are perfect for small-scale operations, while the semi-continuous and fully continuous-type rubber pyrolysis machines provide higher capacity for large-scale industrial applications. The equipment is designed for efficient operation, with capacities ranging from small 100kg/batch to large-scale 50Ton/Day waste rubber processing and recycling.

Bacth/Semi-continuous/fully continuous type RPO pyrolysis machine

Bacth/Semi-continuous/fully continuous type RPO pyrolysis machine

If you're seeking a sustainable and profitable recycling solution for waste rubber materials processing, our RPO pyrolysis machine is the perfect choice. With its efficient operation, environmental benefits, and compliance with EU environmental policies, it's an investment that pays off in both economic and ecological terms. Contact us today to learn more about how our pyrolysis machine can transform your waste into wealth!