Tel/WhatsApp

Tel/WhatsApp

Nylon is a synthetic polymer widely used in textiles, automotive parts, and packaging due to its durability and resistance to heat and wear. However, its long lifespan and resistance to natural decomposition also pose a significant environmental challenge. Mechanical recycling, the common method for nylon, has limitations with contaminated or mixed waste.

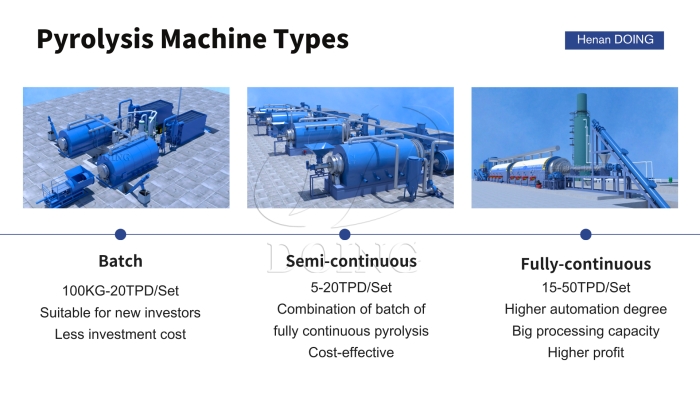

DOING nylon recycling pyrolysis plant process types

DOING nylon recycling pyrolysis plant process types

Fortunately, pyrolysis offers a promising alternative. There is experimental data showing that nylon can be efficiently recycled through pyrolysis because nylon is a thermoplastic polymer. Below is a detailed breakdown of nylon pyrolysis, covering its working principles, process parameters, product outputs, and practical applications.

The working principles of nylon pyrolysis

Nylon pyrolysis is a thermal decomposition process that breaks down nylon’s long polymer chains into smaller molecules under anaerobic or low-oxygen conditions. Unlike combustion, which produces harmful emissions, nylon pyrolysis focuses on controlled heating to maximize the yield of useful products. The core mechanism comprises two key stages:

1.Polymer Chain Cleavage:

Nylon (primarily polyamide-6 or polyamide-66) is heated to high temperatures, causing C-C, C-O, and N-H bonds in its polymer structure to break.

2.Small Molecule Conversion:

The broken chains rearrange into gaseous, liquid, and solid products, which are then separated and collected for further use.

This process of pyrolysis plant is applicable to nylon waste such as PA6, PA66, PA11, PA1010, PA610, and PA1012, including textile waste (excluding PET), plastic parts(excluding PVC), and industrial byproducts—even those contaminated with dirt or other substances.

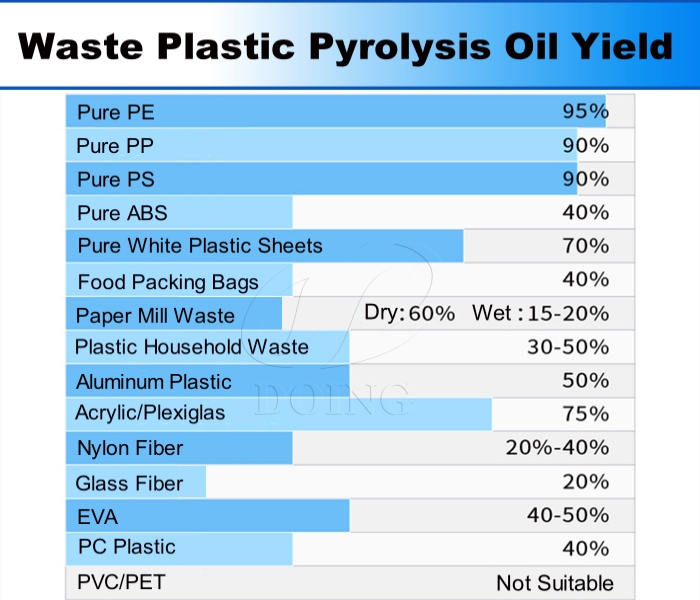

Oil yield from plastic pyrolysis

Oil yield from plastic pyrolysis

The Parameters for nylon pyrolysis

To ensure efficient and consistent nylon pyrolysis, two critical parameters need careful control:

1. Temperature

The optimal temperature range for nylon pyrolysis is 500–800°C. Lower temperatures (500–600°C) favor liquid product formation, while higher temperatures (700–800°C) increase gas yields. Excessively high temperatures can reduce liquid and gas output by promoting solid product formation.

2. Reaction Time

Reaction time affects the completeness of polymer decomposition. Typically, 1–3 hours of residence time in the reactor ensures full breakdown of nylon chains. Longer reaction times may boost product yields but can increase energy consumption.

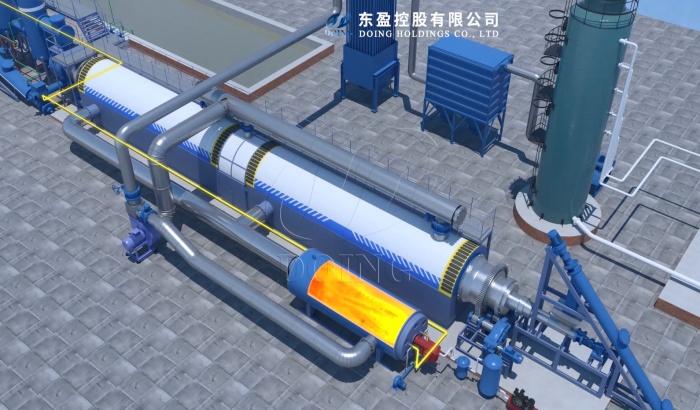

PLC control system of nylon pyrolysis plant

PLC control system of nylon pyrolysis plant

DOING pyrolysis plant is equipped with a PLC control system, which can remotely control the pyrolysis temperature and time in real time to ensure optimal product output. Each product has its practical application:

1.Liquid Products

The liquid fraction includes aromatic hydrocarbons (benzene, toluene, xylene) and organic acids. These can be used directly as fuel oil for boilers, brick factories, glass factories, steel mills, cement plants, and gypsum plants,or further processed into diesel fuel for diesel generators, trucks, tractors, ships, and other heavy machinery.

2.Solid Products

The solid residue is primarily carbon black and small amounts of ash, with a high calorific value of 23 MJ/kg, comparable to coal. It can be used as solid fuel, fuel additive, raw material for rubber production, or pigment. The ash can be safely disposed of after pollutant testing.

3.Gaseous Products

Composed of hydrogen, methane, ethylene, and small amounts of carbon dioxide and nitrogen oxides, with a high calorific value of 30–40 MJ/m³. They can be recycled to heat the pyrolysis reactor, thereby improving overall energy efficiency and reducing dependence on external fuels.

DOING nylon recycling pyrolysis plant process

DOING nylon recycling pyrolysis plant process

While pyrolysis is a promising method for nylon recycling, it also presents some challenges. DOING is a leading manufacturer of waste-to-fuel pyrolysis equipment, providing complete pyrolysis production lines from small to large waste. If you want to test whether pyrolysis can recover nylon into fuel and carbon black for profits, you can bring nylon raw materials to our company to test the machine, or purchase small scale pyrolysis equipment for experiments.