Tel/WhatsApp

Tel/WhatsApp

As heating fuel prices continue to rise globally, businesses across various sectors are feeling the pressure. Companies relying on conventional fuels are facing increased operational costs, which can severely impact their profitability. One potential solution gaining traction is the use of waste to fuel recycling pyrolysis technology, an innovative process that transforms waste into valuable energy sources.

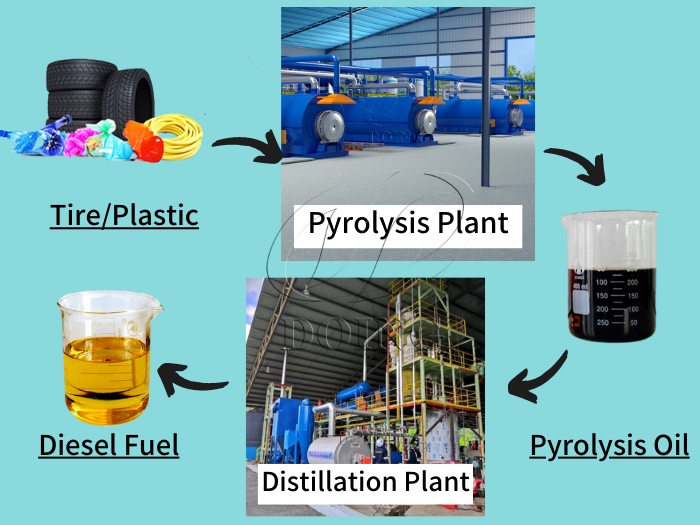

Application of pyrolysis oil

Application of pyrolysis oil

Pyrolysis, a thermal decomposition process, the carbon black and pyrolysis oil obtained from tyres, plastic, oil sludge, etc. can be used as industrial heating oil. This article explains why pyrolysis oil works as a heating fuel, how it cuts costs, and how DOING waste to fuel recycling pyrolysis equipment help businesses adopt this alternative.

Why Pyrolysis Oil is a Feasible Heating Fuel Alternative

Heating systems (e.g., industrial boilers, asphalt mixing plant furnaces) have less strict fuel requirements than car engines—they tolerate wider ranges of viscosity, sulfur, and calorific value. Pyrolysis oil, when properly processed, meets these needs perfectly:

1. Calorific value matches traditional heating fuels

Pyrolysis oil has a calorific value of 42–45 MJ/kg, which is comparable to common heating fuels like heavy fuel oil (HFO, 40–44 MJ/kg) and diesel (45–46 MJ/kg).

2. Low cost compared to traditional fuels

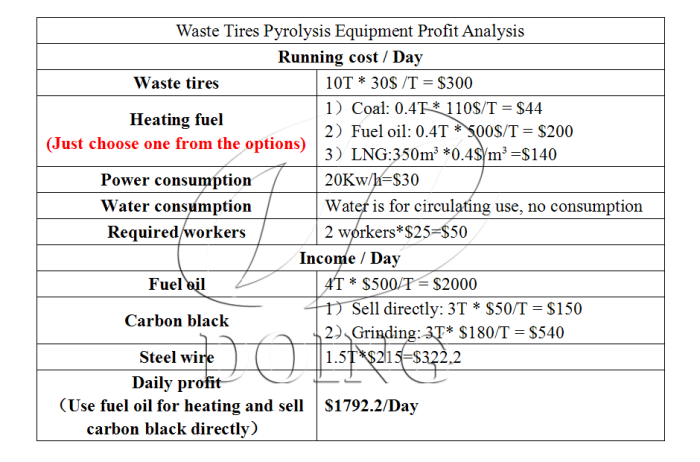

The biggest advantage of pyrolysis oil is its low production cost. Unlike diesel or natural gas (which are tied to global oil/gas prices), pyrolysis oil is made from waste, here’s the cost breakdown:

Raw material cost: Waste tires, plastics, or oil sludge are typically free or very low-cost (for example, in most regions, waste tires cost $50-100 per ton, and some countries even provide subsidies for tire collectors).

Tire pyrolysis profit analysis

Tire pyrolysis profit analysis

Production cost: Producing one ton of pyrolysis oil requires approximately 2.5 tons of waste tires and approximately 80-100 kWh of electricity. The total production cost is typically $150-250 per ton, 50-70% cheaper than diesel ($600-800 per ton) and 30-40% cheaper than heavy fuel oil ($350-450 per ton).

3. Can be integrated into existing heating systems

Most industrial heating systems can use pyrolysis oil with minimal modifications:

Burners: Standard diesel/HFO burners work with pyrolysis oil by adjusting the fuel pressure and nozzle size.

Storage: Pyrolysis oil can be stored in existing fuel tanks.

Safety: Pyrolysis oil has a flash point of >55°C (meeting industrial safety standards for heating fuels), so no additional safety equipment is needed beyond what’s already in place for traditional fuels.

How DOING Waste to Fuel Recycling Pyrolysis Equipment Enable Cost Savings

To use pyrolysis oil for heating, businesses first need reliable equipment to produce high-quality pyrolysis oil. DOING waste to fuel recycling pyrolysis equipment (designed for waste tires, plastics, or oil sludge) is specifically designed to meet industrial heating needs of cement, glass, ceramic, steel, and gypsum plants. DOING also offers pyrolysis oil distillation equipment to improve pyrolysis oil quality. Their value proposition is as follows:

Application of pyrolysis oil

Application of pyrolysis oil

1.High oil yield, maximizing fuel production:

DOING equipment utilizes national standard materials and can be customized with stainless steel 304/306/314/316L. It offers uniform heating (350-550°C) and is equipped with an efficient condensation system. This design ensures: Tire-to-oil yield: 42-45% (2.2-2.4 tons of waste tires yield 1 ton of oil). Plastic-to-oil yield: 50-55% (1.8-2 tons of clean plastic waste yield 1 ton of oil). Oil sludge refining rate: 35-40% (2.5-2.8 tons of oil sludge can produce 1 ton of oil). Higher oil yields mean businesses can obtain more fuel from the same amount of waste, thereby reducing the cost per ton of pyrolysis oil.

2.Low-impurity oil, stable heat supply

DOING pyrolysis equipment features built-in purification to ensure high-quality pyrolysis oil. It can be combined with DOING distillation equipment to further improve the quality of the pyrolysis oil, removing color and odor for better use in heating systems. It can also be used directly in diesel generators, tractors, and trucks. Cleaner oil means fewer heating system failures and lower maintenance costs—critical for ongoing industrial operations.

3.Scalable models for different business sizes

DOING offers pyrolysis equipment with capacities ranging from 0.1 TPD to 50 TPD and distillation equipment with capacities ranging from 0.1 TPD to 14 TPD, ensuring a suitable model for businesses of all sizes.

DOING waste to fuel machine

DOING waste to fuel machine

4.Choosing the right raw materials:

Prioritize local, low-cost waste (such as tires, plastics, aluminum-plastic composites, medical waste, oil sludge, coal tar residue, municipal solid waste, and other solid and hazardous waste). DOING pyrolysis equipment can handle all of these.

5.Start small/Customize the project according to your actual pyrolysis oil demand:

Test with a small-scale DOING system, such as a 0.5 TPD frame unit, to verify the compatibility of pyrolysis oil with your heating system, then gradually scale up.

6.Partner support:

DOING provides a comprehensive service offering: We provide raw material testing, equipment installation, operator training, and after-sales maintenance to ensure smooth operation.

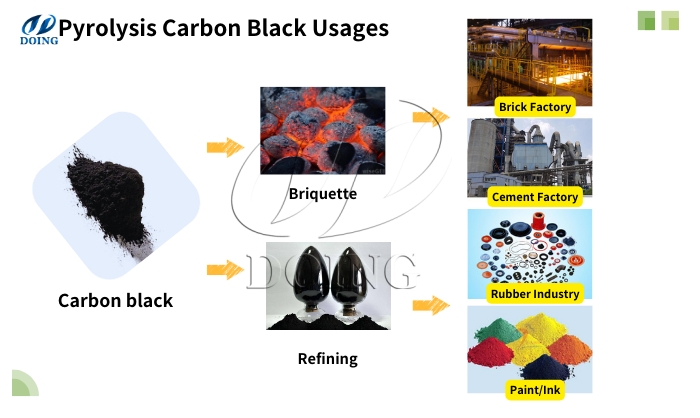

Besides, the charcoal/carbon black obtained from waste pyrolysis can be also used as heating energy for cement industry, because pyrolysis carbon black has a high heating valve similar to coal and some of our customers can directly sell the crude pyrolysis carbon black without any processing to cement factory at quite good price.

Application of carbon black

Application of carbon black

Rising heating fuel prices don't necessarily mean higher operating costs, pyrolysis oil and carbon black are affordable and sustainable alternative suitable for most industrial heating systems. DOING have been dedicated to the R & D of the green pyrolysis technology for more than 14 years. So far our waste pyrolysis projects have spread almost 120 foreign countries all over the world including EU where environmental requirement is very high. Whether you operate a small or large facility, this solution can reduce fuel costs by 30-70% in the long term. Feel free to contact us to learn more about pyrolysis oil applications.