Tel/WhatsApp

Tel/WhatsApp

Nigeria, located in Africa, generates over 32 million tons of solid waste annually, with a significant growth trend. There is a huge market for solid waste recycling amd treatment. Pyrolysis technology, a popular and sustainable waste recycling technology, can be used to process this solid waste in Nigeria, turning it into valuable resources. Solid waste treatment solution pyrolysis machine

Solid waste treatment solution pyrolysis machine

In Nigeria, an average of 50% of municipal waste is reportedly organic, with some cities experiencing this figure as high as 80%. This is where pyrolysis technology comes in. Pyrolysis heats organic waste in an oxygen-free environment, breaking it down into useful products such as fuel oil, carbon black, biochar, and syngas. This thermo-cracking conversion offers an alternative to landfilling and incineration, reducing waste volume and generating energy, even for electricity generation, creating a valuable resource for various industries, including industry and manufacturing.

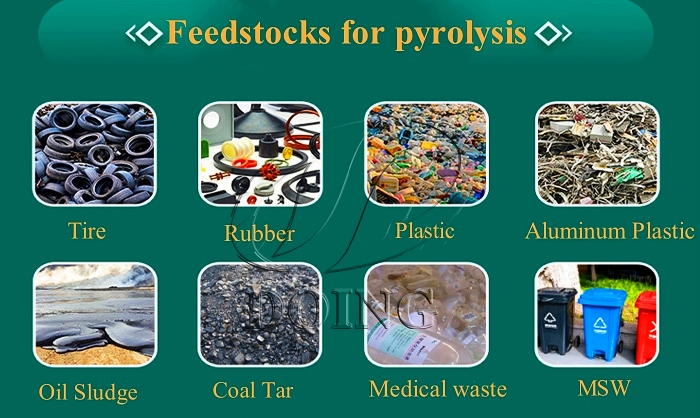

Pyrolysis technology can process a wide variety of solid waste in Nigeria, primarily encompassing four categories:

1. Municipal Solid Waste (MSW):

Plastics: Various types like PE, PP, and PS,agricultural plastic films, aluminum plastic composite materials, mixed plastic, etc. are commonly processed.

Tires and rubber: Includes all types of tires and other rubber products, which yield fuel oil and carbon black.

Other MSW: Sources like paper and certain electronic wastes like PCB Board are also suitable.

2. Biomass: Wood waste and agricultural waste, such as palm kernel shell, cassava processing residue, forest wood waste, peanut shell, rice husk, poultry litter, etc.

3. Specialized waste:

Oil sludge: A mixture of oil, water, and solids, which can be converted into fuel oil.

Medical waste: Non-infectious medical waste is a common feedstock for pyrolysis plants.

Oil Contaminated soil: Pyrolysis can be used to clean up oil contaminated soil.

Solid waste feedstocks for recycling pyrolysis machine

Solid waste feedstocks for recycling pyrolysis machine

And here are the detailed step-by step processing flow about how solid waste recycling pyrolysis machines work:

Step 1: Feedstock Preparation

Before entering the pyrolysis machine reactor, the raw material can be processed to improve pyrolsis efficiency:

Tires: Whole or cut into pieces (depending on pyrolysis machine operation type and the pyrolysis reactor size). Steel belts may be removed first if required.

Plastics: cleaned, and shredded into small flakes or pellets.

Oil Sludge: may need dewatering if the water content is high.

Biomass Materials: crushing, pelleting, or drying into materials with suitable sizes and water content.

Step 2: Feeding into the Reactor

The prepared material is loaded into the pyrolysis reactor, which is sealed to create an oxygen-free environment. Some systems use continuous feed reactors, while others are batch-type depending on the plant design.

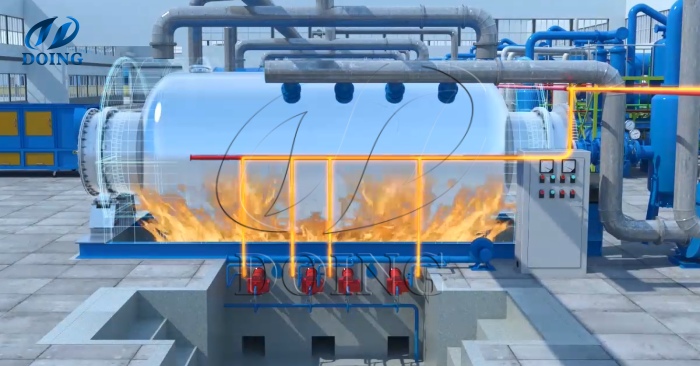

Step 3: Heating the Material

The reactor is heated to temperatures between 250°C to 500°C, depending on the feedstock and desired output. Under heat and pressure, long-chain hydrocarbon molecules in the tires and plastics break down into smaller molecules, mainly oil gas.

Solid waste thermal pyrolysis process

Solid waste thermal pyrolysis process

Step 4: Condensation and oil come out

The vaporized gases travel through a condensing system, where they cool and condense into liquid oil.

Lighter fractions (like gasoline-range hydrocarbons) condense first, followed by heavier oils.

Step 5: Non-Condensable Gases

Gases that don't condense (mainly methane, ethane, propane, hydrogen) are captured and burned in a secondary chamber to generate heat for the reactor — making the system self-sustaining.

Step 6: Solid Residue Collection

For tires: Carbon black, and steel wires remain in the reactor. After cooling, steel wires are separated magnetically.

For plastics/oil sludge: Main solid residue is carbon black-like char, which is collected manually or automatically.

Biomass: mainly the final product biochar.

Step 7: Emission Control & Safety

Modern solid waste recycling pyrolysis machines include: dust removal systems, gas purification system, Odor control unit, etc.which ensure compliance with environmental regulations.

Sustainable solid waste treatment pyrolysis machine environmental devices

Sustainable solid waste treatment pyrolysis machine environmental devices

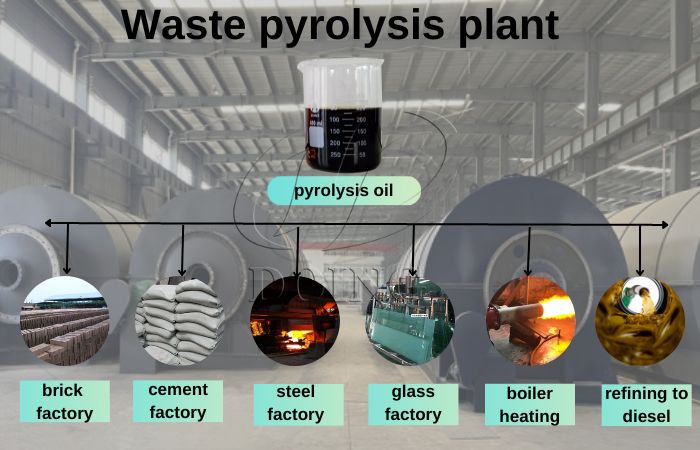

Through above pyrolysis process, solid waste in Nigeria is converted into wealth. Solid waste recycling pyrolysis machines, offer both economic returns and environmental benefits.

Supports a circular economy

By recovering resources from waste, the process contributes to a more sustainable, circular economy. Pyrolysis converts waste into useful products like:

Pyrolysis fuel oil: A liquid fuel that can be used for heating, heavy oil power generation, or further processed into other fuels, like non-standard diesel, base oil, etc. It can displace fossil-based energy, improving energy efficiency.

Solid waste recycling pyrolysis products

Solid waste recycling pyrolysis products

Biochar: A solid residue that can be used as a soil conditioner, to purify water, or as an animal feed additive.

Carbon black: pelleting for heating or for sale in the market.

Syngas: A gas that can be used to generate electricity or heat.

Environmental benefits

Reduces landfill waste: By breaking down waste, pyrolysis significantly reduces the volume of material that needs to be landfilled, saving valuable land resources.

Less pollution: The process produces fewer polluting by-products and lower emissions of harmful gases like carbon monoxide and carbon dioxide compared to incineration.

Prevents groundwater contamination: By removing waste from landfills, it reduces the risk of harmful substances leaking into the groundwater.

Solid waste pyrolysis machine manufacturer---Doing Company services

Solid waste pyrolysis machine manufacturer---Doing Company services

Solid waste treament is no more a major challenge but a business opportunity! If you're planning to set up a solid waste treatment pyrolysis plant in Nigeria or other smiliar situation countries, it's essential to choose the right machine capacity, type of feedstock, and ensure compliance with local environmental regulations for sustainable and profitable operation. China professional pyrolysis machine manufacturer, Henan Doing Group can offer you one-stop services, looking forward to receiving your enquiry!