Tel/WhatsApp

Tel/WhatsApp

Pyrolysis reactor, also called pyrolysis plant/pyrolysis machine/pyrolysis system, is increasingly being used in the recycling industry to convert various types of waste into valuable energy. If you are looking for high quality pyrolysis reactors for sale, DOING Company can customize you suitable solutions at favorable prices. Just check the detailed introduction of our pyrolysis reactor.

DOING pyrolysis reactors for sale projects display

DOING pyrolysis reactors for sale projects display

1. Raw materials and final products of pyrolysis reactor

DOING pyrolysis reactor has wide applications, and it can be used to recycle waste raw materials, such as waste rubber tires, waste plastics, waste oil sludge, coal tar oil, aluminum plastic composite materials, etc., and the final products are fuel oil, carbon black, syn-gas, etc.

Pyrolysis reactor raw materials and final products

Pyrolysis reactor raw materials and final products

2. Types of pyrolysis reactor

Based on more than 13 years of manufacturing and exportation experience, our engineer team has been constantly improving and innovating our pyrolysis reactors. Till now, our pyrolysis reactors have been popular sale in more than 100 countries and regions, and well recognized by our customers. We can provide you with two types of pyrolysis reactors, including batch type and the latest technology - full continuous type.

(1)Batch type pyrolysis reactor for sale

Batch pyrolysis reactors are best suited for small-scale or medium-scale operations. It has the advantages of easy-handling, easy-installation, cost-effective, etc. The cost of batch pyrolysis reactor is from 12,000USD to 76,000USD.

For investors who have a small budget or just want to have a trial running, it's suggested to choose the small scale skid-mounted pyrolysis plant with the capacity of 100KG or 500KG. And we also supply bigger size batch pyrolysis reactors with the daily capacity from 1tons to 20tons.

(2)Continuous type pyrolysis reactor for sale

Continuous pyrolysis reactors are suitable for large-scale operations, and we have the semi-continuous type and fully continuous type. And their capacities vary from 10-50+TPD. The semi-continuous type is more efficient than the batch type pyrolysis reactor, which can pyrolysis 3 batches waste rubber powders in 2 two days.

And for the new technology fully continuous pyrolysis reactor, it can continuously work for about 2 months without stopping to help you obtain more benefits. It has a high automation degree, which is labor and energy saving. The cost of continuous pyrolysis reactor is from 60,000USD~500,000 USD.

When considering the type of pyrolysis reactor to purchase, you need to consider the amount of waste you plan to process, as well as your budget and processing needs.

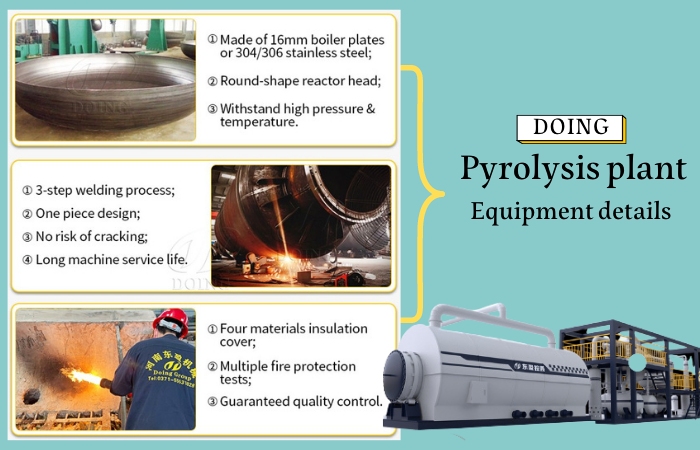

3. DOING pyrolysis reactor quality control

The quality of the pyrolysis reactor is an essential factor to consider before making a purchase. DOING pyrolysis reactor makes a strict control of the machine quality from the following 3 aspects.

(1)Machine design: DOING pyrolysis reactor design adopts external heating, atmospheric pressure, and oxygen-depleted thermal cracking process operation. The reactor furnace body has a good sealing effect, which can ensure that gas won't leak. And it is also equipped with the safety device and environmental protection device to eliminate the hidden dangers and secondary pollution caused by insecurity.

(2)Machine raw material: Our pyrolysis reactor is made of high-quality materials like thickened boiler plate or stainless steel, and the thickness is from 14-20mm, which can withstand high temperatures and pressure. And our pyrolysis reactor has an all-inclusive insulation layer, which can avoid heat less. So our pyrolysis reactor has strong durability and high heating&pyrolysis efficiency. This will not only help you save on energy costs but also ensure maximum productivity and profitability.

DOING pyrolysis reactor machine design advantages

DOING pyrolysis reactor machine design advantages

(3)Machine fabrication: All the welding and manufacturing of our pyrolysis reactor are conducted by our skilled engineers. The pyrolysis reactor welding adopts a 3-step welding process, which is not easy to crack and has a long service life.

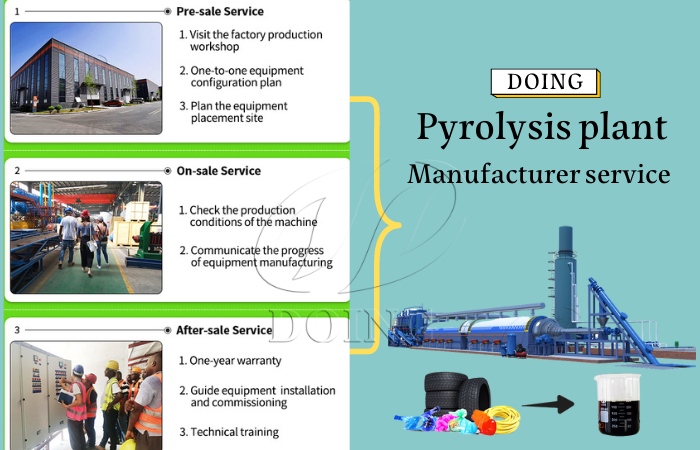

4. DOING pyrolysis reactor purchasing customer service and support

Finally, it is essential to consider the customer service and support provided by the supplier. It is advisable to choose a pyrolysis reactor supplier that offers technical support, installation, and commissioning services. This will ensure that you have access to assistance throughout the lifespan of the pyrolysis reactor. We have a professional sales team and an engineering team to offer you full-circle services as the following pictures show.

Pyrolysis reactor manufacturer services offered by DOING

Pyrolysis reactor manufacturer services offered by DOING

In conclusion, the purchase of a pyrolysis reactor requires careful consideration of several factors that we talked about above. Taking the time to evaluate these factors will help you make an informed decision and select a pyrolysis reactor that meets your specific requirements. And you will find that Henan Doing Company is a good choice for you!