Tel/WhatsApp

Tel/WhatsApp

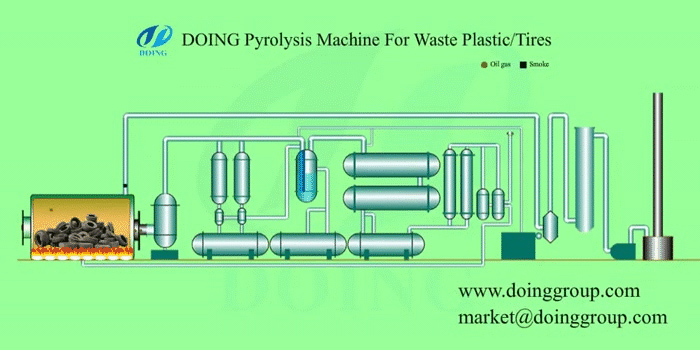

The advent of cars has greatly promoted the development of society and improved the quality of our life. But on the other hand, the waste tires produced by automobiles pose a huge threat to our living environment. DoingGroup has developed the batch waste tire pyrolysis plant, the pyrolysis plant is the use of high temperature cracking chemical reactions, and the waste tires cracked into fuel, carbon black, steel wire, combustible gas process.

DoingGroup batch waste tire pyrolysis plant

DoingGroup batch waste tire pyrolysis plant

The main working process of batch waste tire pyrolysis plant

Batch waste tire pyrolysis plant working process

Batch waste tire pyrolysis plant working process

1. Use mechanical waste tires to enter the reactor and close the inlet to prevent gas flow out.

2. Carbon, wood or fuel heating reactor, when the reactor is generally 200-300 degreesthe cracking reaction began, and the waste tires vaporized into oil vapor.

3. The hydrocarbons entering the condensing system are liquefied into oil and collected in the tank unit. Our system has a negative pressure device, he can greatly enhance the production of pyrolysis oil.

4. Liquefied petroleum gas that can not be liquefied under atmospheric pressure is returned to the reactor as fuel for combustion, which is not only energy saving and environmental protection.

5. After the completion of oil production, the reactor will be cooled. When the temperature drops to 40 degrees, the carbon black and wires will be removed automatically or manually.

Installed batch waste tire pyrolysis plant

Installed batch waste tire pyrolysis plant

Unique advantages of batch waste tire pyrolysis plant

1. Reactor press standard manufacturing, the use of 16mm thick boiler steel pipe and arc pressure head, can withstand high pressure and high temperature.

2. High standard 3-step welding process, not easy to crack, long service life.

3. Pinion rotation device, small power, does not directly contact the reactor, heat transfer less easily deformed.

4. The three stage cooling system uses tube condensers, also known as heat exchangers, which are currently the most commonly used and best performing condensers in the oil industry. Can ensure that the cracked oil and gas fully cooled, high oil production.

Batcj waste tire pyrolysis plant cooling system

Batcj waste tire pyrolysis plant cooling system

5.Safety device oil-water separator, water seal, vacuum device, to ensure the safe and efficient operation of the waste tire pyrolysis plant.

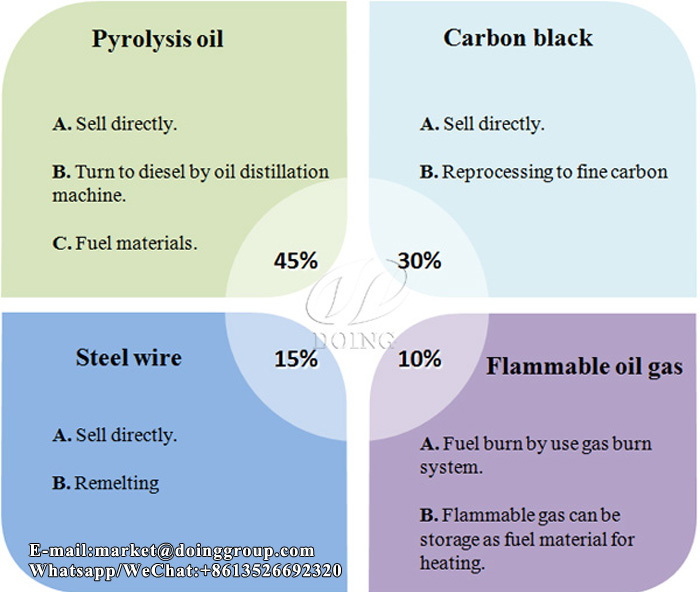

The final products cracked by the batch waste tire pyrolysis plant mainly include fuel oil, carbon black, steel wire and combustible gas.

The final products of batch waste tire pyrolysis plant

The final products of batch waste tire pyrolysis plant

Final products uses in life

1. Fuel oil: Mainly used in steel mills, boiler heating, heavy oil generating units, cement plants and so on.

2. Carbon black: Can be used for pressure ball burning, can also be used for refined toner. Refined toner for new tires, rubber soles and pigments.

3. Steel wire: Can scrap recycling, can also be re-cast into other steel.

4. Combustible gas: The system was re-collected for reactor heating.

Final product uses

Final product uses

In the past ten years, as the leader in the machinery manufacturing industry, DOING company has been adhering to the enterprise spirit of quality first, integrity management, won the praise of customers at home and abroad.

At present, the batch waste tire pyrolysis plant of DOING company has spread to more than 70 countries and regions all over the world. If you are interested in our pyrolysis plant, welcome to visit us.