Tel/WhatsApp

Tel/WhatsApp

Coal tar is a black or dark brown viscous liquid with a pungent odor generated during the dry distillation and gasification of coal. Among many complex and high-cost treatment methods such as dehydration distillation, hydrocracking, and catalysis, pyrolysis of coal tar is undoubtedly the better solution by virtue of its advantages of high efficiency, ease of operation, and environmental protection.

Next is a detailed explanation of coal tar pyrolysis machine and its working process.

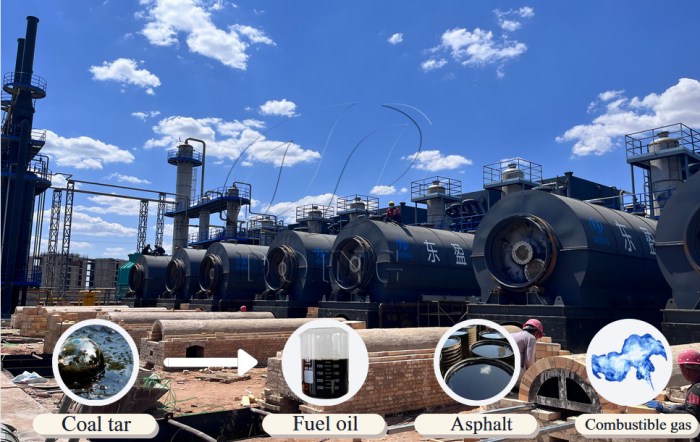

1. DOING coal tar pyrolysis machine for sale

There are two main types of coal tar pyrolysis machine for sale of DOING Company: continuous coal tar pyrolysis and batch type coal tar pyrolysis machine. Though pyrolysis of coal tar, we can obtain fuel oil, carbon black, syn-gas products from coal tar pyrolysis machine.

DOING coal tar pyrolysis machine for sale

DOING coal tar pyrolysis machine for sale

The working processes of these two types of coal tar pyrolysis machines are basically the same, which are mainly distinguished by the degree of automation, processing capacity and whether they are continuous production.

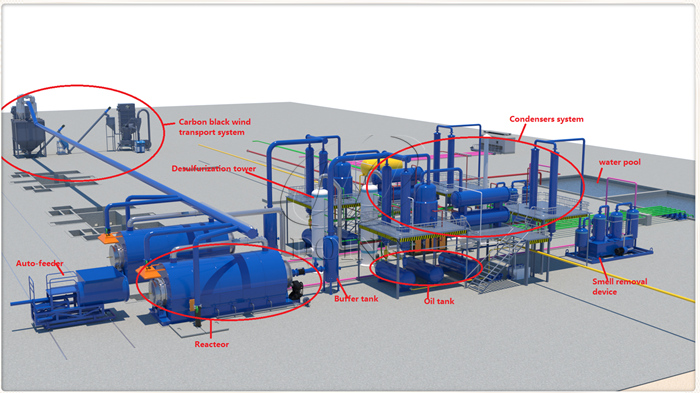

Coal tar pyrolysis machine mainly consists of a series of equipment such as pyrolysis reactor, buffer tank, condensation system, oil-water separator, water seal, desulfurization tower, slag discharge system and negative pressure vacuum device. The detailed configurations of the coal tar pyrolysis machines may vary according to the processing scale requirements.

Detailed equipments of DOING coal tar pyrolysis machine

Detailed equipments of DOING coal tar pyrolysis machine

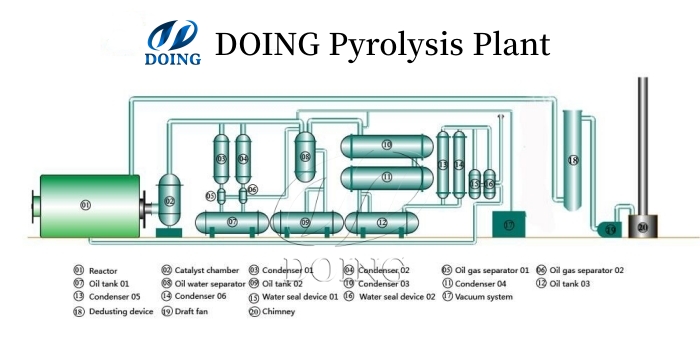

2. Working process of DOING coal tar pyrolysis machine

First, the coal tar enters the pyrolysis reactor through an automatic feeding device for high-temperature pyrolysis. When the temperature in the reactor reaches 250°C, oil gas begins to be produced. Then, the generated oil gas enters the buffer tank to slow down the flow of oil gas and settle impurities one after another; and then entering the condensation system, the oil gas is fully cooled into liquid oil;

The remaining non-condensable gas will enter the tail gas purification device, and after purification treatment, it will be returned to the reactor for combustion as fuel; when the temperature of the reactor is cooled to 50°C, the residual material in the furnace - carbon black residue - can be discharged and collected.

Working process of DOING coal tar pyrolysis machine

Working process of DOING coal tar pyrolysis machine

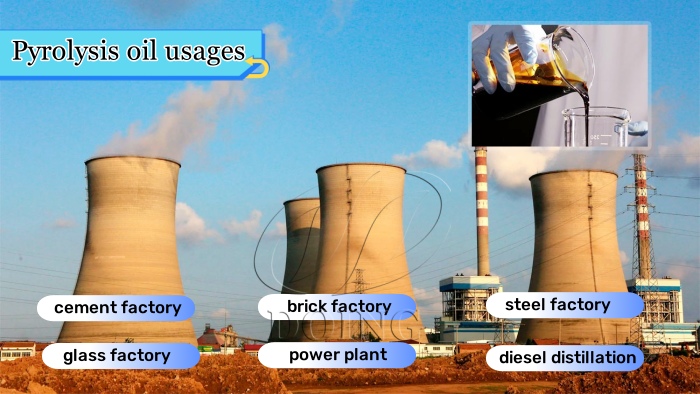

Fuel oil obtained from coal tar pyrolysis machine is beige (or orange), clear and translucent, and hasa high calorific value, which can be widely used in industrial and civil fuel fields, such as glass factories, cement factories, steel factories, heavy oil generators, etc. And they can partially replace diesel for power and have a wide range of uses.

Applications of fuel oil extracted from coal tar pyrolysis machine

Applications of fuel oil extracted from coal tar pyrolysis machine

The carbon black residue produced by the pyrolysis of coal tar can be directly sold as raw materials for building bricks and mixed soil.

The coal tar pyrolysis machine developed and designed by Henan DOING Company has gone through technological changes and innovations, providing a good example for the green and resource utilization of coal tar residues. So if you are interested in our coal tar pyrolysis machines for sale or want to learn more other information, just feel free to contact us. Looking forward to cooperating with you.