Tel/WhatsApp

Tel/WhatsApp

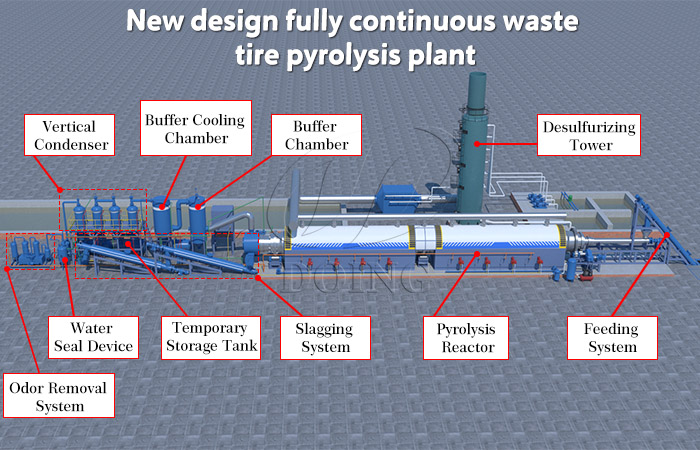

Continuous process manufacturing pyrolysis plant 3D drawing

Continuous process manufacturing pyrolysis plant 3D drawing

Pyrolysis is a thermochemical decomposition of orgnic material at elevated temperatures in the absence of oxygen. Pyrolysis typically occurs under pressure and at the operating temperatures at 430℃. Pyrolysis is a special case of thermolysis, and is the most commonly used for organic materials, being, therefore, one of the processed involved in charring. In general, pyrolysis os organic substances produces gas and liquid products and leaves a solid residue richer in carbon content. Extreme pyrolysis, which leaves mostly carbon as the residue, is called carbonization. The process is used heavily in the chemical industry, for example, to produce charcoal, activated carbon, methanol, and other chemicals from wood, to convert ethylene dichloride into vinyl chloride to make PVC, to produce coke from coal, to convert biomass into syngas, to turn waste into safely disposable substances, and for transforming mediumweight hydrocarbons from oil into lighter ones like diesel or gasoline. All these specialized used of pyrolysis may be called various names, such as dry distillation, destructive distillation, or cracking, but all same principle.

For us, we mainly specialized in manufacturing and supplying waste tire/plastic/rubber pyrolysis plant, mostly for processing the rubber products to get fuel oil. On one hand, with the modernization of the society, rubber industry develops at a rapid speed, rubber manufactures are widely used in many field of life. On the other hand, the pollution of scrap rubber or plastics is increasing for its difficulty in disposing safely, which is also called “Black Contamination”, has become a big threat to the environment and is getting increasingly serious.

Continuous process manufacturing pyrolysis plant

Continuous process manufacturing pyrolysis plant

Continuous process manufacturing pyrolysis plantIn the early years, the most commonly used pyrolysis plant is mainly the batch operation process, which has low investment but complicated operation process and high labour cost. Withthe technology improving and customers’ requests, we DOING Company developed a new technology continuous process manufacturing pyrolysis plant. This continuous process manufacturing pyrolysis plant has fully automatic process, which can be controlled by PLC system or computer, thus to save the labour cost. And with the automatic and continuous feeding and discharge system, it can make the the pyrolysis system keep running 24/7 without stop, thus to save the valuable time and energy which are consumed in the batch manual operation system.

Continuous process manufacturing pyrolysis plant

Continuous process manufacturing pyrolysis plant

If you want to know more information about our continuous pyrolysis plant, please feel free to contact us. We have the whole pyrolysis line installed in our factory, welcome for your visiting!