Tel/WhatsApp

Tel/WhatsApp

DOING company has been committed to the research and manufacture of pyrolysis plant for more than 10 years, and we have developed fully continuous waste plastic pyrolysis plant, which can process the waste plastics by pyrolysis technology continuously. This kind fully continuous waste plastic pyrolysis plant has higher environmental protection, larger processing capacity and higher oil yield.

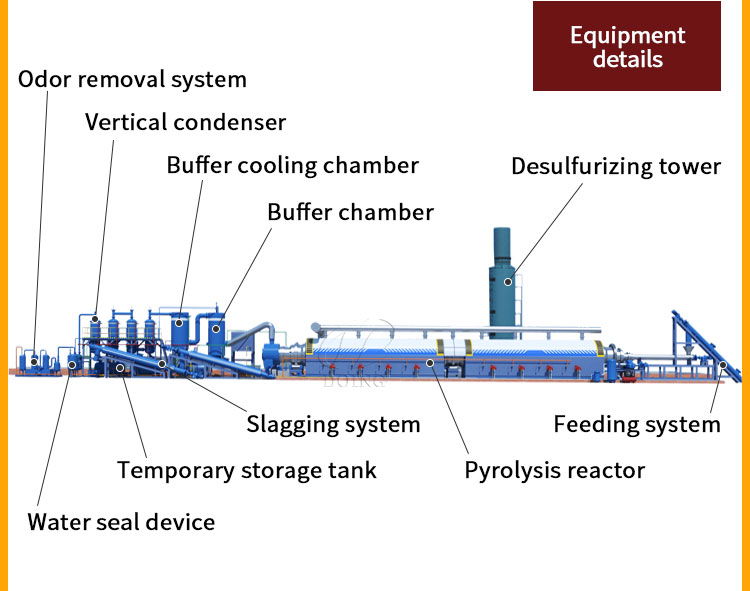

DOING fully continuous waste plastic pyrolysis plant

DOING fully continuous waste plastic pyrolysis plant

Main components of fully continuous waste plastic pyrolysis plant

Fully continuous waste plastic pyrolysis plant includes plastic crushing system, continuous feeding system, continuous rotating pyrolysis reactor, continuous slagging system, continuous cooling system, continuous tail gas cleaning and odor removal system, desulfurizetion & purification tower, etc.

Main components of fully continuous waste plastic pyrolysis plant

Main components of fully continuous waste plastic pyrolysis plant

Main working process of fully continuous waste plastic pyrolysis plant

1. Pretreatment

Crush waste plastics into 2-3 cm pieces by plastic crushing system. If your waste plastics is wet, you should dry it first. Because the dry waste plastics have a shorter processing time.

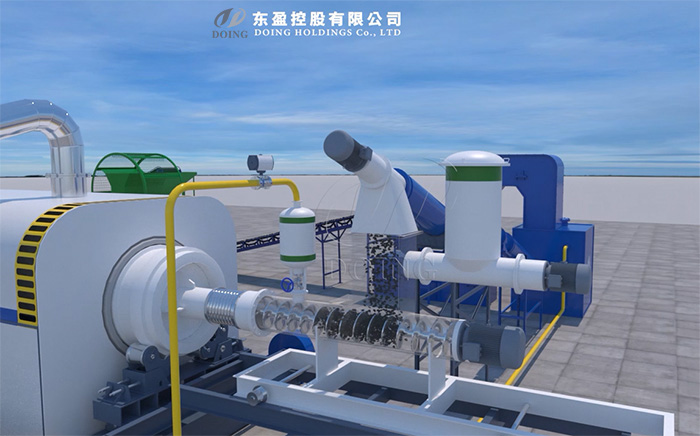

2. Feeding

Feed the crushed waste plastics into pyrolysis reactor by the continuous feeding system automatically.

Feeding waste plastics

Feeding waste plastics

3. Pyrolysis

Heat pyrolysis reactor by heating fuel in heating furnace. At this point, the pyrolysis reactor will rotate evenly, so that the plastic uniformly heated. When the waste plastics reach a certain temperature, they will be pyrolyzed into oil gas.

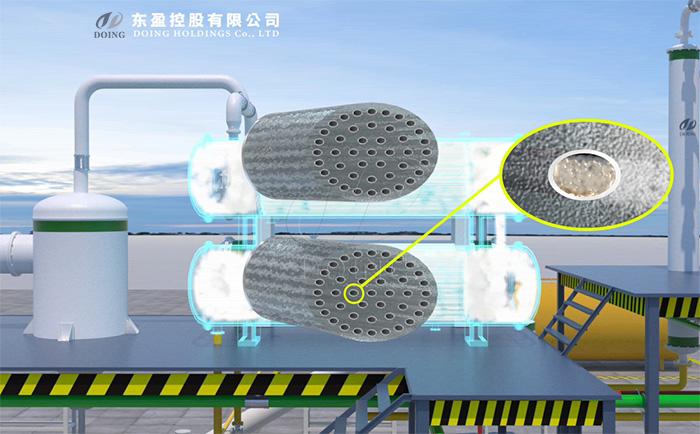

4. Condensing

The generted oil gas will flow into the cooling system, and be cooled into liquid oil then collected into oil tank. The cooling system we adopt is the new-type condenser which can improve the oil yield efficiency and make the oil yield to the maximum.

Tube cooling system

Tube cooling system

5. Waste gas recovery and treatment

In the oil gas, there is some uncondensable gas which can be recycled to heat the reactor as fuel, saving energy and reduce fuel costs for customers. The exhaust gas produced by the combustion will be treated by tail gas cleaning and odor removal system and desulfurizetion & purification tower, so that the final emissions gas can meet the environmental protection standards and will not cause pollution to the environment.

6. Discharge

As oil gas is produced, carbon black is produced in the pyrolysis reactor. When the whole pyrolysis process is over, the carbon black can be discharged in one go through the continuous slagging system. And it can be cooled during the discharge process to a temperature at which we can directly pack and collect, saving cooling time and increasing productivity.

Desulfurizetion & purification tower is working

Desulfurizetion & purification tower is working

Final products and their applications

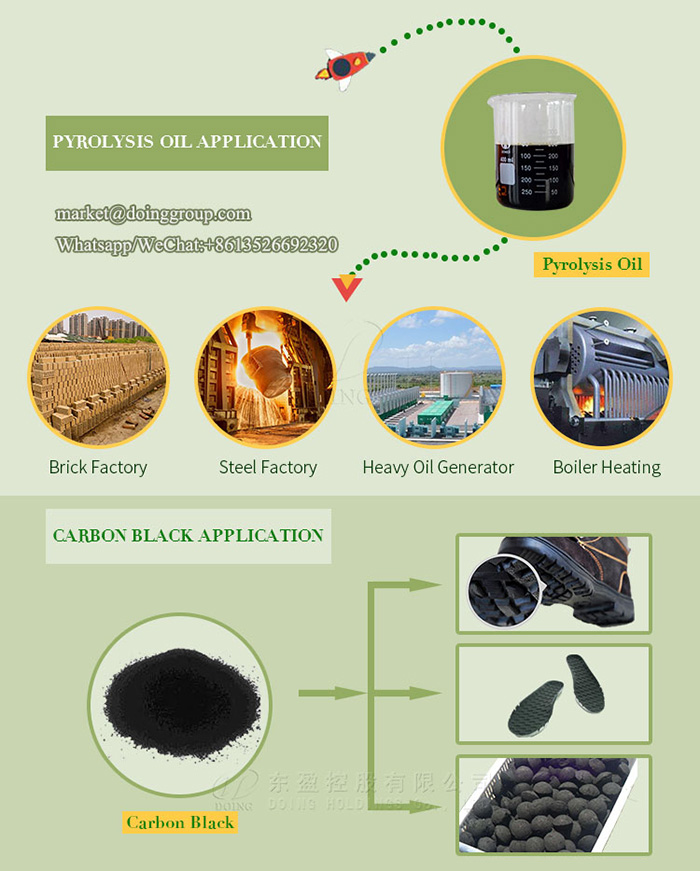

1. Fuel oil

The main product produced by this fully continuous waste plastic pyrolysis plant is fuel oil which can be widely used for industrial and commercial purposes, such as power plant factory, glass factory, cement factory, ceramic factory, etc.

2. Carbon black

Carbon black can be reprocessed into high quality carbon by the carbon black grinding machine or briquetting for burning.

3. Uncondensable gas

In addition, we get about 10%uncondensable gas during pyrolysis process. The main component of this uncondensable gas are methane (CH4), and we cannot condense this gases. But we can use this gases to heat the pyrolysis reactor as fuel or collect them for other heating applications.

Fuel oil and carbon black applications

Fuel oil and carbon black applications

Unique advantages of DOING fully continuous waste plastic pyrolysis plant

1. High oil output

Fully continuous waste plastic pyrolysis plant is equipped with an accurate calculation system to ensure that waste plastics is fully pyrolyzed in the reactor, and ensure the high oil output.

2. Environmental protection

The fully continuous waste plastic pyrolysis plant with DOING latest technology is equipped with advanced environmental protection system, such as continuous tail gas cleaning and odor removal system and desulfurization & purification tower. By the advanced environmental protection system, exhaust gas can be treated effectively and clean.

Environmental protection system

Environmental protection system

3. Large processing capacity

Fully continuous waste plastic pyrolysis plant has large processing capacity than the batch waste plastic pyrolysis plant. For example, our fully continuous waste plastic pyrolysis plant is 20TPD, 30TPD, 50TPD and 100TPD. So our fully continuous waste plastic pyrolysis plant is more suitable for some larger capacity projects.

4. Automatic feeding and slag discharge

Fully continuous waste plastic pyrolysis plant has the features of continuous feeding, continuous automatic slagging, continuous oil discharge day and night. It requires only one or two person to control the PLC console. Feeding and slag discharge can be realized in a fully automatic manner. No manual work is required, which saves time and effort for customers, saves costs and improves profits.

5. Unique sealing design of both feeding and slagging system

Our system is sealed during feeding and slag discharge. This design can ensure the safety and environment protection.

6. Saving cost

The non-condensable flammable exhaust gas after plastic pyrolysis can be used as the heat source for the pyrolysis reactor, saving fuel costs and increasing profits.

Tchnical data of fully continuous waste plastic pyrolysis plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-100 | |||

| 2 | Cpacity | 20T/D | 30T/D | 50T/D | 100T/D | |||

| 3 | Power | 50Kw | 65Kw | 80Kw | 120Kw | |||

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black, uncondensable gas | ||||||

DOING adheres to the business philosophy of “Quality First, Credit Foremost”, providing the best pre-sales and after-sales service and the most professional technical support to our customers, controlling the product quality strictly and constantly improving the machine design and production technology. Now, our products have sold well in more than 60 countries and regions around the world, winning great praise and trust of our customers all over the world!

In addition, after more than ten years of accumulation, whether it is raw materials or final products, DOING have a wealth of channels. So when you do plastic pyrolysis projects,we can provide for you not only the high quality fully continuous waste plastic pyrolysis plant, but also source of raw material or the product sales. Welcome to contact us.