Tel/WhatsApp

Tel/WhatsApp

Nowadays, plastic products are extensively used all around the world and the plastic waste can be seen everywhere. We can make full use of the waste plastic and convert it into fuel oil.

In this case, DOING company has developed and manufactured the waste plastic recycling to fuel oil machine---pyrolysis plant that can convert waste plastics into fuel, carbon black and combustible gases at high temperatures. So far it can be said that waste plastic recycling to fuel oil machine is the most ideal way of plastic recycling.

Waste plastic recycling to fuel oil machine

Waste plastic recycling to fuel oil machine

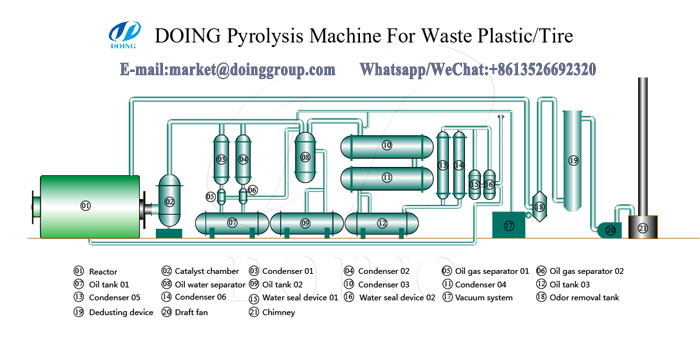

Some people may wonder, how can waste plastic be turned back into fuel oil? How does pyrolysis plant turn into oil? Next, let's take a look at the main working process of waste plastic recycling to fuel oil machine.

1. Put waste plastics into the reactor by automatic push device, close the feeding door and open heating system of the waste plastic recycling to fuel oil machine.

2. When the temperature reaches 160 degrees Celsius, the oil gas will be released. When the temperature rises between 200 degrees Celsius and 300 degrees Celsius, the fuel oil yield is highest.

3. These oil gas will enter the condensing system, a part of which will be liquefied and flow into the oil tank. The other part will be liquefied through the condensing system to liquefy into heavy oil and flow into the tank.

4. The resulting heavy oil will be filtered through the dedusting and deodorizing device. Remove fumes, dust particles generated during combustion of the fuel.

5. When the temperature of waste plastic recycling to fuel oil machine drops to about 40 degrees Celsius, the black carbon is discharged automatically.

Working process of waste plastic recycling to fuel oil machine

Working process of waste plastic recycling to fuel oil machine

Knowing the working process of waste plastic recycling to fuel oil machine, you may be more interested in the profits. After our engineers accurately test and running one set 10T/D waste plastic recycling to fuel oil machine, he found that waste plastic recycling to fuel oil machine can earn a net profit of at least $2,000 a day. These benefits mainly come from the fuel oil and carbon black produced by waste plastic recycling to fuel oil machine.Both of fuel oil and carbon black have a wide range of uses in life, as follows:

Fuel oil application:

Fuel oil application

Fuel oil application

1. Fuel oil: Mainly used in heavy industries like steel plants, heavy oil power plants, various furnaces and boiler heating, heavy oil generators, cement/brick/glass manufacturing plants. It also can be refined to diesel oil with the help of pyrolysis oil distillation plant.

Carbon black application:

Carbon black application

Carbon black application

2. Carbon black: Mainly used for pressure ball burning and refined milling. Which refined flour and can be used for new tires, rubber soles, pigment manufacturing materials.

In addition, DOING's waste plastic recycling to fuel oil machine has unique advantages:

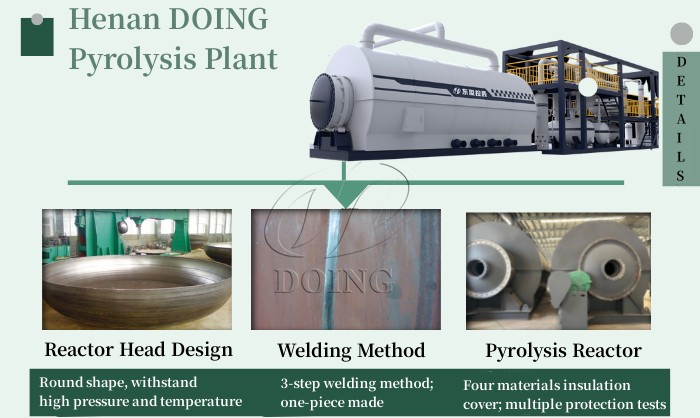

1.16mm, Q245R thick steel boiler plate/stainless steel, curved pressure pyrolysis reactor head, can withstand high temperature and high pressure.

2. Unique 3-step welding process, longer service life.

DOING waste plastic to fuel oil machine design detaisls

DOING waste plastic to fuel oil machine design detaisls

3. The most widely used condenser with best performance in petroleum industry is adopted. The cooling system of the waste plastic recycling to fuel oil machine is divided into three stages to ensure that the pyrolysis oil gas is fully cooled and the oil yield is increased.

4. Water separator, water seal, vacuum devices and other safety devices can provide negative pressure to prevent its back and can purify oil gas and exhaust gas. It can meet different countries' emission standard.

If you are looking for high quality environmental waste plastic to fuel oil machine---pyrolysis plant for sale, please feel free to leave your inquiry to Henan Doing Company. Our professional sales and engineer team can customize suitable mini small scale to big scales waste plastic to fuel oil pyrolysis solutions. We also have many successful project cases and running sites of waste plastic to fuel oil machines for your reference.