Tel/WhatsApp

Tel/WhatsApp

On August 18, 2025, DOING 14TPD new type tire pyrolysis oil to diesel distillation machine, customized for a Zambian customer—was officially loaded and shipped. Here is the delivery video:

From order confirmation to factory production and final shipment, the entire process took just three months—highlighting DOING exceptional efficiency and commitment to providing high-quality solutions to customers worldwide.

To ensure the client can start tire pyrolysis oil to diesel production immediately after receiving the machine, DOING shipment includes a full set of supporting machine and materials, not just the core distillation machine:

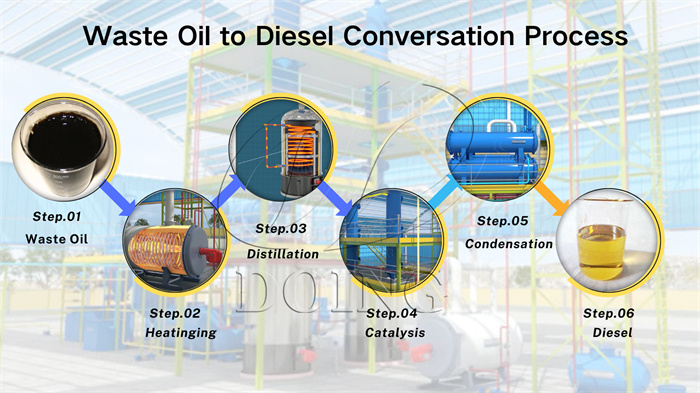

①14TPD new type distillation machine: The core machine for tire pyrolysis oil distillation, integrated with feeding, heating,distillation, condensation, functions. It efficiently removes impurities such as heavy metals, and colloids from tire pyrolysis oil , converting it into high-quality diesel with a calorific value of 42-45 MJ/kg.

②Thermal oil boiler: Provides a stable, high-temperature heat source for the distillation process. Its energy-saving design reduces heat loss by over 5%, helping customers save on subsequent operating costs.

Shipment of DOING tire pyrolysis oil distillation machine to Zambia

Shipment of DOING tire pyrolysis oil distillation machine to Zambia

③Burner: Utilizes the non-condensable gases produced as a byproduct of the distillation process as fuel, enabling energy recycling and reducing customers' reliance on external energy sources.

④DOING patented catalyst: DOING innovative catalytic distillation process is suitable for countries where acid and alkali cleaning agents are difficult to purchase and is more efficient than acid and alkali cleaning processes.

⑤Operation manual and spare parts kit: Detailed multilingual (English + local language) operation guides and common spare parts (filters, valves, etc.) to avoid production suspension due to part damage.

DOING tire pyrolysis oil distillation machine process

DOING tire pyrolysis oil distillation machine process

DOING 14TPD new type tire pyrolysis oil to diesel distillation machine is expected to arrive in Zambia in approximately one month. Following delivery, DOING will provide the necessary installation services tailored to the client’s requirements, ensuring the smooth and efficient operation of the machine from day one. Please look forward to the subsequent operation status.