Tel/WhatsApp

Tel/WhatsApp

DOING used plastic to diesel recycling plant which adopted advanced technique and machine design can split waste tyres & plastic & rubber into black plastic fuel oil (after catalytic pyrolysis will get high quality diesel). Black plastic fuel oil rate is about 45%-90%. And diesel oil recovery rate can be 85%- 90% with used plastic to diesel fuel plant.

Used plastic to diesel fuel plant

Used plastic to diesel fuel plant

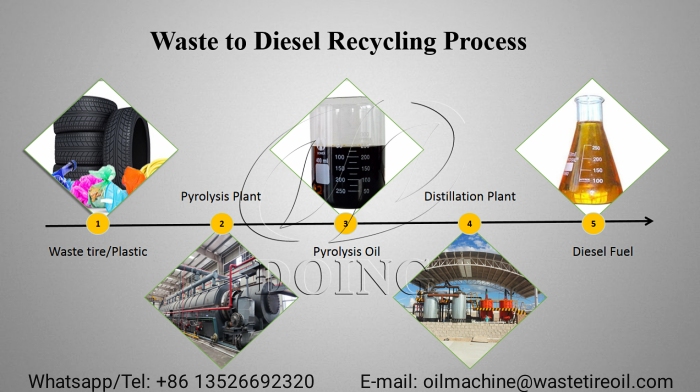

Our latest technology for recycling used plastic to diesel fuel, also named plastic to diesel plant, needs two systems working together: one is the pyrolysis plant for recycling and cracking the waste plastic into plastic pyrolysis oil, and the other is waste oil distillation plant for recycling black plastic oil into 85% non-standard diesel fuel and the remaining is asphalt). How to recycle black plastic oil into diesel fuel?

1. Plastic to Oil Pyrolysis Process:

Feedstock Preparation: Waste plastics, like PP, PE, PS, ABS, mixed plastic waste, household plastic scrap, agricultural plastic films, plastic bags, aluminum plastic waste materials, plastic medical wastes, paper mill waste, etc. are collected and sorted.

Feeding: These plastics are fed into a pyrolysis reactor, often under low oxygen or vacuum conditions.

Pyrolysis: Inside the reactor, the plastics are heated to temperatures ranging from 200°C to 400°C. This heat causes the long polymer chains in the plastics to break down into smaller molecules without burning them.

Plastic Oil Condensation: As the plastics decompose, they release gases that cool and condense into a liquid state, forming a crude oil-like substance, that's plastic pyrolysis oil.

2. Plastic Pyrolysis Oil Distillation Process:

First, to pump black plastic fuel oil into distillation diesel fuel plant.

Second, we need to heat black plastic fuel oil and keep it in a best temperature for best diesel quality. Fuel oil will be converted to diesel oil gas when get heating. Then our cooling system will cool diesel fuel oil gas into diesel fuel.

Next pump diesel fuel oil into odor and color removal system for remove which will purify further diesel fuel with special catalyst.

Finally, you can get 85% diesel from our black plastic oil to diesel fuel plant.

Used plastic to diesel fuel plant

Used plastic to diesel fuel plant

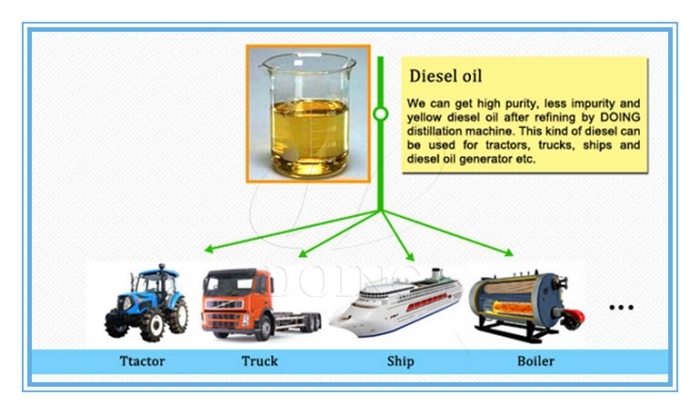

Diesel fuel got from used plastic to diesel fuel plant can be used in the diesel engines found in most freight trucks, trains, buses, boats, heavy machinery, and farm and construction vehicles. Some cars and small trucks also have diesel engines. Diesel fuel is used in diesel engine generators to generate electricity. Most remote villages and other locations, use diesel generators to supply electricity. Many industrial facilities, large buildings, institutional facilities, hospitals, and electric utilities also have diesel generators for backup and emergency power supply.

Diesel fuel application and uages of used plastic to diesel plant

Diesel fuel application and uages of used plastic to diesel plant

Used plastic to diesel plant offers a potential solution for managing and recycling plastic waste while producing valuable energy resources. More machine details and detailed specification parameters, welcome to send your inquiry to Henan Doing Company.