Tel/WhatsApp

Tel/WhatsApp

With the development of automobile industry, tyre demand is increasing day by day. According to statistics, 50%-55% raw rubber are used for tyre manufacture every year. However, waste tyre pollution problem exists in each countries. More and more waste tyres not only take up the farmland but also become a breeding ground for diseases, which causes pollution and threaten people’s life. Henan Doing produced fully automatic waste tyre pyrolysis plant can solve the problem. Through continuous improvement and constant technology upgrading, Doing have designed the fully automatic waste tyre pyrolysis plant which can convert tyre into useful resources more efficiently.

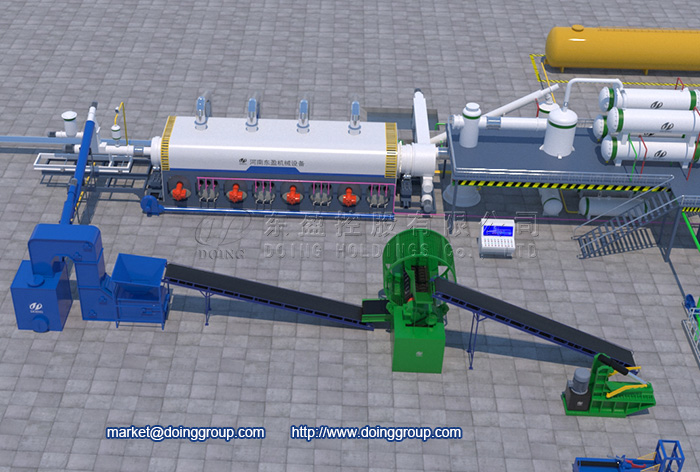

DOING fully automatic waste tyre pyrolysis plant

DOING fully automatic waste tyre pyrolysis plant

Fully automatic waste tyre pyrolysis plant advantage

1. Automatic control, simple operation

The fully automatic waste tire pyrolysis device of dongying company is controlled by PLC system, which can realize automatic feeding and discharging, and it only needs 1-2 people to complete the operation.

2. Sufficient pyrolysis to increase oil yield

The fully automatic waste tire pyrolysis unit of dongying company deals with the broken waste tires, and the raw materials can be fully cracked to improve the oil yield.

3. Continuous operation to improve equipment utilization

Dongying company automatic continuous waste plastic thermal decomposition device, can continue feeding, continuous discharge, at least 10 tons of waste tires per day, up to 100 tons per day, equipment utilization is relatively high.4. Zero emission.In the dedusting system, three steps are used to dedust the hot smoke from reactor, more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged in the air directly.

Fully automatic waste tyre pyrolysis plant working process

Shred tyres

Use a specialized tyre shredder to process big whole tyres into 3-5cm small pieces for easy feeding. The tyre shredder is a single and fully automatic shredding system, which can be directly connected to the feeding system of the continuous pyrolysis plant, which no need any transfer process.

Continuous pyrolysis process

Shredded tyres go into the continuous waste tyre pyrolysis plant, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous feeding tyres to the carbon black dischrge system for discharge.

DOING fully automatic waste tyre pyrolysis plant

DOING fully automatic waste tyre pyrolysis plant

Process Description:

a. Heating in advance to make the temperature of the reactor rises up to about 300℃, fuel choose can be gas or oil.

b. Turn on the auto-feeder, small pieces of tyres loaded into reactor and pyrolysis begins; reaches certain temperature and the gas oil is generated from the waste.

c. Oil gas generated and condensed into fuel oil stored, sync gas recycled and used as fuel during operation; at the same time, carbon black and steel wires in short also discharged from the auto-discharging system. The Steel metal and carbon black separated automatically and stored.

d. Since one batch begins, it lasts for about 20days continuously, without any stop.

e. Then stop the motor, and do the maintenance. The next batch of process begins again.

End product and usage of fully automatic waste tyre pyrolysis plant:

| NO | Name | Percentage | Usage |

| 1 | Tyre fuel oil | 45-52% | 1.Can be sold directly; 2.Can be as fuel; 3.Can be used industrial and commercial purposes. |

| 2 | Carbon black | 30-35% | 1.Can be sold directly 2.Can be used electric cable jacketing,black nylon bag,rubber additive |

| 3 | Steel wire | 10-15% | 1.Can be sold directly 2.Make steel bloom by use hydraulic press-packing |

| 4 | Oil gas | 10% | 1.Can be as fuel burn by use gas burning system 2.Extra gas also be storage as fuel for other heating |

Notes: The tyre oil is widely used as fuel oil in industries such as steel & iron factories, ceramics or chemical industries or hotels, restaurant etc.

Specifications of the fully automatic waste tyre pyrolysis plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on theraw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

If you are interested in our fully automatic waste tyre pyrolysis plant, please feel free to contact us.