Tel/WhatsApp

Tel/WhatsApp

Pyrolysis is the most economical and effective method of recycling tyre, which can convert waste tyres into valuable substances such as fuel oil, carbon black, steel wire, etc.. This passage introduces you to the type, process, profits, product uses, advantages of recycling tyre to oil process by pyrolysis plant.

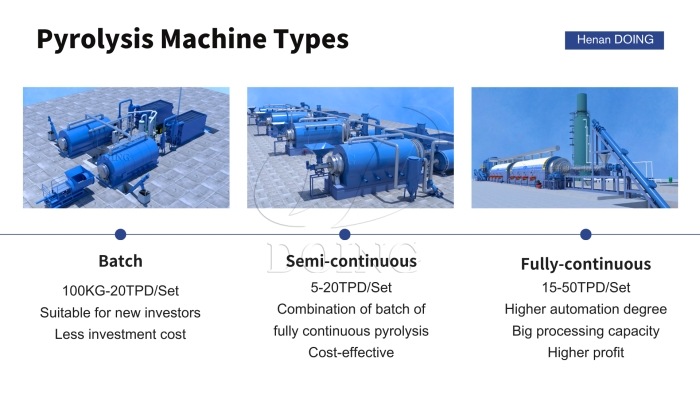

With the improvement of pyrolysis technology, DOING designed three types of recycling tyre to oil process by pyrolysis plants: batch type, semi-continuous type and fully-continuous type. They have different capacities and features as the following picture shows:

Batch/semi-continuous/fully-continuous DOING recycling tyre to oil process by pyrolysis plants

Batch/semi-continuous/fully-continuous DOING recycling tyre to oil process by pyrolysis plants

1.Feeding: The batch type could feed the whole waste tyre into the reactor by auto-feeding system or labor. The semi-continuous type and fully-continuous type feed the rubber powder by screw conveyor.

2.Pyrolysis: Heat the pyrolysis reactor with fuel. 280-320° is the most suitable temperature to crack into oil and gas.

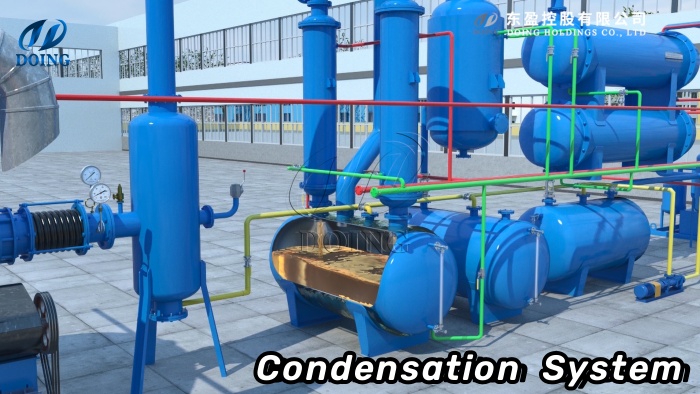

3.Cooling: The oil and gas enter the condensation system through the oil and gas pipeline and are fully cooled into oil and stored in the temporary storage tank.

Cooling system of recycling tyre to oil process by pyrolysis plant

Cooling system of recycling tyre to oil process by pyrolysis plant

4.Exhaust gas treating: The waste gas and waste dust generated enters the environmental protection purification device treatment system to remove.

5.Carbon black collection: When the temperature of the reactor drops below 40 degrees, the batch type collects the carbon black and steel wires, the semi-continuous type and fully-continuous type collect the carbon black at high temperature.

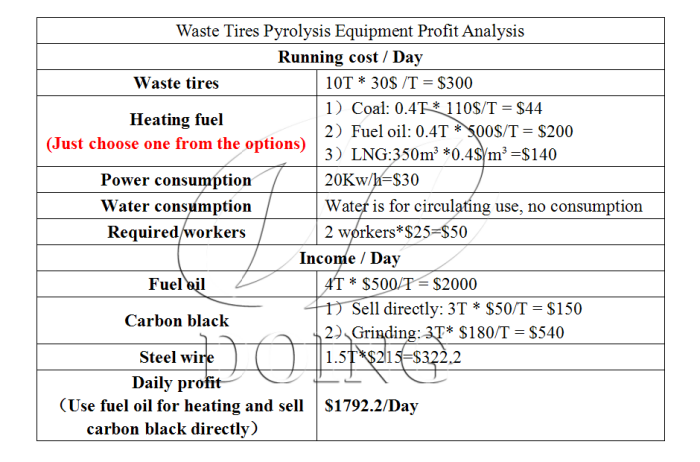

(Take the 10-ton batch type waste tyre processing pyrolysis plant as an example. Based on customer feedback and market research, the specific data will fluctuate)

The profit of waste tyre processing pyrolysis plant

The profit of waste tyre processing pyrolysis plant

These gains mainly come from the fuel oil, carbon black, steel wire cracked from waste tyres.

1.Fuel oil: Mainly used in iron and steel plants, boiler heating, heavy oil generators, and cement plants.

2.Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tyres, rubber soles, and pigments.

3.Steel wire: Sold to wire recycling plants or remelted into new products.

The product uses of waste tyre processing pyrolysis plant

The product uses of waste tyre processing pyrolysis plant

1.Safety:

①The head of reactor adopts arc design and is pressed at one time, with strong pressure resistance and high safety.

②Equipped with oil-water separator to prevent oil and gas back-flow.

③The vacuum system ensures that the entire tyre production line runs well.

4.Equipped with combustion chamber uses electric ignition, no manual operation required, ensuring the personal safety of workers.

2.Environmental protection:

①Water circulation pool:water circulating used to prevent the waste water produced.

②Gas purification system: Flammable and non-condensable gases pass was cleaned to fuel to heat the reactor through exhaust gas cleaning treatment plant. Non-flammable non-condensable gases were removed by purification desulfurization tower effectively that are irritating to the human body, ensuring that the exhaust gas emissions meet the monitored emission quality standards.

Environmental friendly DOING recycling tyre to oil process by pyrolysis plant

Environmental friendly DOING recycling tyre to oil process by pyrolysis plant

③DOING pyrolysis system adopts a fully enclosed design and is equipped with a dust collector to ensure that smoke and dust do not leak out during the entire pyrolysis process.

3. High oil yield: Multi-layer condenser tubes can fully cool the oil and gas to ensure 100% oil and gas recovery rate.

4. Durable: Made of national standard materials Q245R/Q345R boiler plate, and we can customize the stainless material depending on your needs.

5. Energy saving: The syngas generated during the pyrolysis process can be recycled and used as fuel in the reactor.

DOING waste tyre recycling pyrolysis equipment

DOING waste tyre recycling pyrolysis equipment

DOING three types of waste tyre processing pyrolysis plants meet the processing volume and raw material requirements of various customers, and have won praise and trust from all over the world. DOING was established in 2011 and has 13 years of production and export trade experience. If you have any needs, please contact us. We will provide you with one-stop service. Looking forward to our cooperation.