Tel/WhatsApp

Tel/WhatsApp

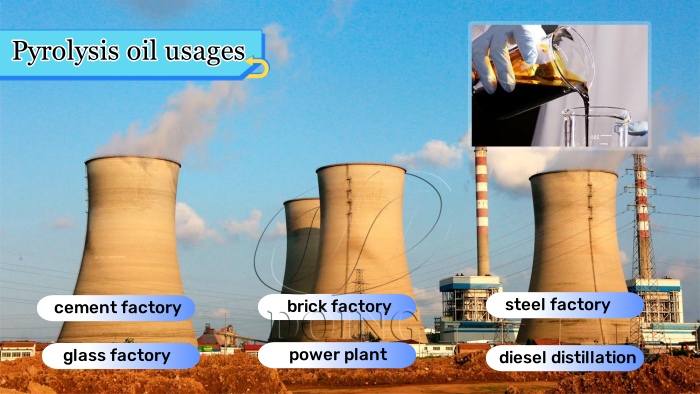

With the increase of waste tyre resources, to make the full utilization of them, the tyre pyrolysis plant project has become a popular business, which adopts the new green pyrolysis technology to effectively convert waste tyre to pyrolysis oil, carbon black and steel wire. The pyrolysis oil from tyre pyrolysis plant can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries etc.

Pyrolysis oil obtained from tyre pyrolysis plant application

Pyrolysis oil obtained from tyre pyrolysis plant application

And to further enlarge its application and market, more customers selected the tyre oil refining process plant to make further purification for the tyre pyrolysis oil. After purifying, we can obtain about 85% diesel oil, 10% bitumen and 5% syn gas. The diesel oil got from this plant in high quality and can be used for tractors, trucks, generators, boilers, agricultural vehicles etc., the bitumen can be used for paving or make further refining, the syn gas will recycle to furnace as the auxiliary heating fuel.

Diesel obtained from tyre oil refining process plant application

Diesel obtained from tyre oil refining process plant application

In addition, apart from tyre pyrolysis oil, the tyre oil refining process plant can also treat a variety of other waste, such as waste motor engine oil, used lube oil, crude oil, plastic pyrolysis oil, etc., which all can get good quality diesel oil with excellent color and qualified smell.

And now to meet the various demands of customers, some factories have researched different distillation technologies for tyre oil refining process plants. Among them, DOING Group is one which has abundant project experience and received lots of good feedback. The next is a brief introduction of the tyre oil refining process plant researched by DOING engineers:

1. Work process of Tyre oil refining process plant

Feeding tyre oil into refining reactor, and start heating; during the refining process, control temperature to ensure get good quality diesel. When oil gas comes out, oil gas goes through the catalyst system and cooling system, then we can get diesel. And if you want to make further purification, you can pump diesel to odor removal and color removal systems. The following is a short video to display the whole process of the tyre oil refining process plant work:

2. Advantages of tyre oil refining process plant

(1) High environmental protection

DOING tyre oil refining process plant is equipped with tail-gas cleaning system and desulfurization tower to purify exhaust gas to meet the emission standards in various countries.

Desulfurization tower for tyre oil refining process plant

Desulfurization tower for tyre oil refining process plant

(2) High work safety and efficiency

The equipment adopts the latest automation technology, just needs a few technicians to work, highly enhancing work safety and efficiency. And the materials and production process of the equipment are strictly supervised and meet all safety standards.

DOING safe tyre oil refining process plant for sale

DOING safe tyre oil refining process plant for sale

(3) Multiple choices

Here DOING provides two kinds of tyre oil refining process plant with the processing capacity between 100kg per day to 14+ tons pre day, adopting different refining technology and designs. Customers can select a suitable one based on their requirements. Also, we can provide a customized scheme for you.

Various schemes of tyre oil refining process plant

Various schemes of tyre oil refining process plant

DOING tyre oil refining process plant has been exported to many countries and put into operation, such as Indonesia, Malaysia, Ghana, Mexico, South Africa, Japan, Thailand, Mali, Colombia, etc. If you also want to invest in the project, just feel free to contact DOING directly!