Tel/WhatsApp

Tel/WhatsApp

Waste oil distillation process plant

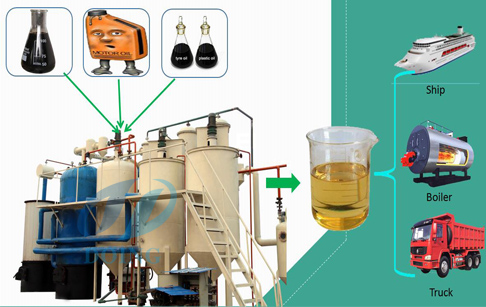

Waste oil distillation process plant is project of Doing group use the sludge,waste engine oil, tyre pyrolysis oil,plastic pyrolysis oil, sump oil as raw material, use the special distillation and refining technology to get oil. Waste oil distillation process plant can make the oil yield reach as high as 80%-90%. Doing company is in the leading level in machinery, technology. marketing, research and development

Waste oil distillation process plant

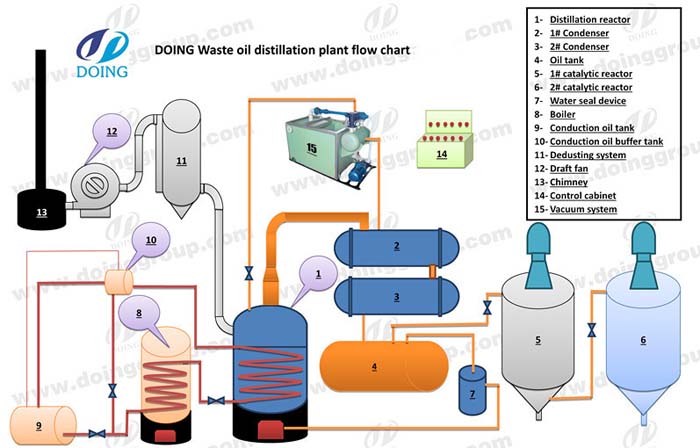

Waste oil distillation process plant is self-shunt vacuum distillation unit, distillation system uses a tube furnace (independent research) heating the continuous distillation process under negative pressure to be waste oil distillation.Because the waste oil contains large amounts of water so we should dehydration before distillation.For example, the raw material ( like used engine oil) recovery is more than 90% when the water percentage is less than 5%.

Waste oil distillation process plant distillation waste oil to diesel

Waste oil distillation process plant can be used for refining waste oil, waste engine oil, sludge, pyrolysis oil (tyre pyrolysis oil and plastic pyrolysis oil) and sump oil into qualified diesel fuel. And the diesel oil can be directly used in low speed engines and generators

In the process of waste oil distillation process plant,The cold materials (waste oil) should be pre-heat exchanger with the overhead vapor phase component first.Materials after heat exchange into the falling film evaporator using secondary heating flue gas dehydration,and then through the tube furnace heating again after after the temperature meet the process requirements into ectification within the column Control reflux ratio at the same time, On the top of the gas phase components after heat exchange with the raw condensation receiving tank into the light components, To restructuring after restructuring of condensing tank,Tank bottom components into the slag,Non-condensable gas back into the tube furnace combustion after water seal.