Tel/WhatsApp

Tel/WhatsApp

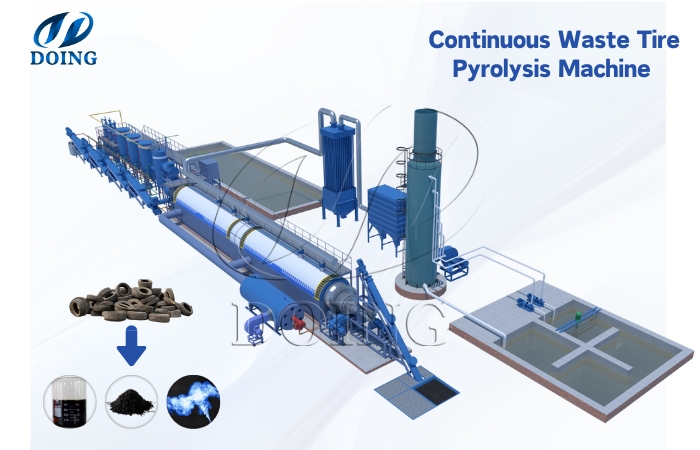

Continuous waste tire pyrolysis machine is a new type of waste tire to fuel oil processing equipment, which can keep continuous production for over 45 days and has obvious advantages in safety, environmental protection, energy saving and high efficiency compared with batch type waste tire pyrolysis machine.

DOING continuous waste tire pyrolysis machine for sale

DOING continuous waste tire pyrolysis machine for sale

Raw material pretreatment for continuous waste tire pyrolysis machine

For the continuous production of the continuous waste tire pyrolysis machine, we need to process waste tires into rubber powder about 2mm previously. Of course, the continuous waste tire pyrolysis machine can also recycle other waste, such as waste plastics, medical waste, municipal solid waste, etc., and they also need to be processed into small pieces.

Pretreatment device for continuous waste tire pyrolysis machine

Pretreatment device for continuous waste tire pyrolysis machine

Obtained final products from continuous waste tire pyrolysis machine

For continuous waste tire pyrolysis machine, we can main obtain three parts of final products:

Fuel oil(46-50%): Its application ranges from fuel for industrial boilers to heavy oil factories like cement factories, steel factories, glass factories, offering a viable alternative to fossil fuels.

Carbon black(40-42%): Carbon black has a calorific value comparable to high-grade coal; therefore, it can be used as fuel either in pulverized or briquetted form. It can also be used as a chemical strengthener in rubber and coloring agent in pigment industries.

Applications of obtained products

Applications of obtained products

Syn-gas(10-12%): The main component of this gases are methane (CH4), so we can not condense and store this gases. After purifying, the gas can be used to heat the pyrolysis reactor or used for other heating application.

Parameters of continuous waste tire pyrolysis machine

| Item | Specifications | ||||

| Model | DY-C-15 | DY-C-20 | DY-C-30 | DY-C-40 | DY-C-50 |

| Capacity | 15T/D | 20T/D | 30T/D | 40T/D | 50T/D |

| Feedstock | Waste tires/plastic/rubber/medical waste, etc. | ||||

| Output | Fuel oil, carbon black, syn-gas | ||||

| Thickness | 14/16/18/20mm | ||||

| Heating type | Indirect heating | ||||

| Required workers | 1-2 workers per shift | ||||

| Heating fuel | Fuel oil, natural gas, coal, wood | ||||

| Reactor materials | Q345R(304ss/316ss/309ss/310ss material could be customized) | ||||

| Cooling type | Circulating water cooling | ||||

| Cooling system | Shell tube condensation system | ||||

| Land occupy size | Take 50TPD machine as an example, it’s about 700 m² | ||||

Continuous waste tire pyrolysis machine 3D video display

Continuous waste tire pyrolysis machine features

1. Fully automatic PLC control system: PLC control system to make precise control of the whole operation of tire pyrolysis, such as temperature and heating time control, pressure control, oil collecting control, carbon black discharging control, etc. Also it can be customized based on your requirements.

2. Continuous production and discharging: continuous production for over 45 days without stop, enhancing work efficiency and save much time cost.

PLC control system for continuous waste tire pyrolysis machine

PLC control system for continuous waste tire pyrolysis machine

3. Reliable safe operation control: DOING continuous waste tire pyrolysis machine adopt the best material and latest method for manufacturing to ensure the good quality of pyrolysis machine. Also the continuous waste tire pyrolysis machine is equipped with some safety devices, such as negative pressure vacuum device, safety valve, pressure gauge, temperature sensor, alarm device, water seal, etc.

4. High standard environmental protection system: during the whole pyrolysis process, there won't produce any pollution in terms of water, dust, air. DOING can provide different environmental protection systems based on your demands, such as tail-gas cleaning system, desulfurization tower, carbon black wind transfer system, etc.

Environmental protection systems for continuous waste tire pyrolysis machine

Environmental protection systems for continuous waste tire pyrolysis machine

Continuous waste pyrolysis machine some projects display

| Raw material | Project location | Project capacity | Project display |

| Waste tires | India | 50TPD |  |

| Waste plastics | Brazil | 50TPD |  |

| Waste rubber | Russia | 50TPD |  |

| Waste tires | America | 50TPD |  |

| Waste tires | Kazakhstan | 30TPD |  |

| Waste tires | China | 50TPD |  |

Over tens of years development and updating of DOING pyrolysis technology, DOING continuous waste tire pyrolysis machines have cooperated with many customers and received lots of good feedback. If you also want to invest in the project, just feel free to contact us, our engineer and sales team can customize suitable scheme based on your demands.