Tel/WhatsApp

Tel/WhatsApp

Tyres pyrolysis equipment for 8T

Tyres pyrolysis equipment for 8T

1) High oil yield 2)Pollution-free 3)Sigmoid wanter cooling pipe 4)Internal gear 5)Good sale service 6)Certification: CE,SGS,ISO.

DY-8T Hot Sale tyres pyrolysis equipment With High Quality

safety

1) Pressure gauge, alarming device, safe valve.

2) We have anti-clogging device, in case of jam, there will be antomatic alaiming, automatic exhaust and automatic decompression.

3) Using Q245R /Q345R boiler plate. The thickness of reactor by fire is 16mm.

4) Automatic welding, processing according to standard of head of pressure vessel.

5) With proprietary vacuum system, it is much safer on condition of negative pressure.

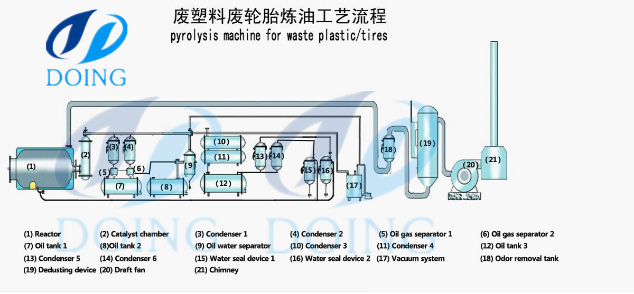

Working process

1) Waste plastic refinning flow: plastic separation → automatic feed → catalytic cracking→ oil-water separation → cooling liquid → crude oil → flammable gas recovery → flammable gas combustion → desufuration and dust removal

2) Waste tires refining flow: tire broken → automatic feed → catalytic cracking → oil-water separation → cooling liquid → carbon black emission → carbon black processing → crude oil → flammable gas recovery → flammable gas combustion → desulfuration removal

Energy saving

1) Exhaust gas recycle to furnace

2) Continuous feeding with automatic feeder, no gas leak.

Environmental protection

1) Built-in slagging, seal with water, no solid pollution.

2) With dust removal equipment there is no air pollution.