Tel/WhatsApp

Tel/WhatsApp

Can you reuse waste oil? Yes. But It's not recommended reuse waste oil directly. Understand the generation and characteristics of waste oil, and learn how we can achieve eco-friendly and practical reuse of various waste oils with the help of waste oil regeneration.

What counts as waste oil?

Waste oil refers to used oil that contains impurities such as metal particles, water, and oxidation residues. Due to contamination, degradation, or depletion of additives, it can no longer serve its original purpose.

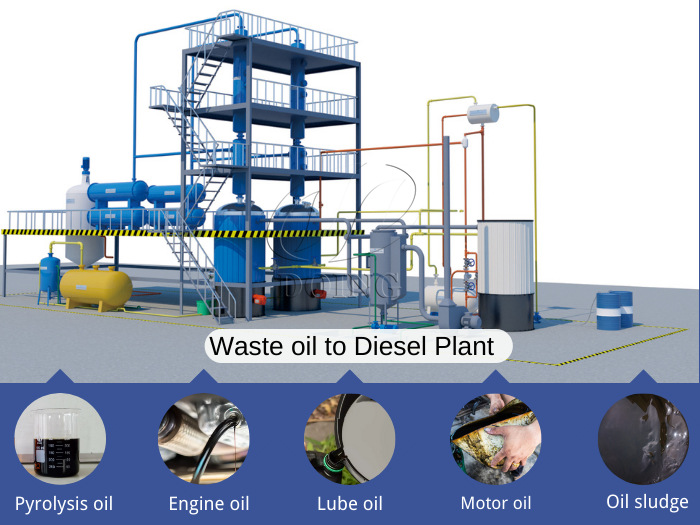

Oil that can be recycled into diesel

Oil that can be recycled into diesel

1.Used motor oil: From cars, trucks, or industrial machinery (contaminated with metal particles, dirt, or fuel).

2.Waste industrial oil: From manufacturing, hydraulics, or heat transfer systems (may contain chemicals, sludge, or wear debris).

3.Pyrolysis oil: A byproduct of waste plastic/rubber/sludge pyrolysis (It can be directly used as heating fuel for industrial boilers/ brick factories, glass factories, gypsum factories, cement factories, steel factories/ heavy oil generators, but for wider applications such as diesel generators, trucks, tractors, ships, and other heavy machinery, pyrolysis oil requires refining to meet reuse standards).

Why waste oil can’t be reused directly

Waste oil accumulates harmful contaminants during use:

1.Solid impurities: Metal shavings (from engine wear), dirt, and carbon deposits can clog filters, scratch engine parts, or cause abrasion in machinery.

2.Liquid contaminants: Water (from condensation or leaks) reduces lubricity and causes rust; fuel diluents (in used motor oil) lower the oil’s flash point, increasing fire risks.

3.Chemical byproducts: Oxidation and thermal degradation produce acidic compounds and sludge, which corrode metal surfaces and break down lubricating properties.

Reusing waste oil benefits

Reusing waste oil benefits

Directly reusing such waste oil not only shortens equipment lifespan but also violates environmental regulations.Therefore, professional processing is essential. Advanced regeneration technology can purify waste oil and and convert waste oil into high-quality reusable diesel—and DOING waste oil regeneration machine is a leader in making this process efficient, safe, and profitable.

How DOING waste oil regeneration machine machine enables reuse

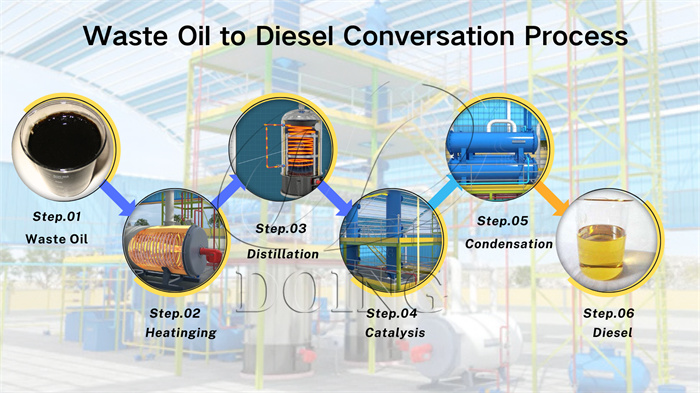

1. Feeding: First turn on the oil pump to pump the waste oil into the regeneration machine reactor until the reactor is full of waste oil, then close the reactor door.

2.regeneration machine: Turn on the burners and start heating the reactor. As the temperature continues to rise, the oil-gas will be continuously distilled out.

3.Cooling/Catalysis:

①Oil-gas will enter the cooling system through the pipeline. The circulating water in the cooling system will cool the oil-gas into liquid oil, which is then purified by adding an acid-base catalyst. After refining, the oil vapor is transferred to the oil tank.

DOING waste oil regeneration machine process

DOING waste oil regeneration machine process

②The oil-gas enters the catalytic tower, where it is refined by adding DOING patented catalyst. It then enters the cooling system, where it is cooled into liquid oil and transferred to the oil tank.

4.Decolorization and deodorization: The liquid oil in the oil tank is pumped into the decolorization and deodorization tanks through the oil pump to remove the wax and gum in the liquid oil, remove the unpleasant smell of the liquid oil, remove odor and purify the color.

What are the benefits of reusing waste oil:

1.Environmental Impact: Reduces pollution by recycling waste oil instead of waste oil dumping.

2.Cost-Effective: Saves money by reusing oil, reducing the need for new raw materials and fossil fuels.

3.Sustainability: Supports a circular economy by reprocessing waste into usable products, regenerated diesel and asphalt/bitumen.

4.Cost Savings: For businesses, reusing waste oil as fuel lowers operational costs.

DOING waste oil regeneration machine

DOING waste oil regeneration machine

Waste oil isn’t “waste”—it’s a reusable resource, and DOING waste oil regeneration machine machine makes reusing it efficient, safe, and profitable. Whether you are looking to cut costs, reduce environmental impact, or create a new revenue stream, DOING solution turns waste oil into value, please contact us immediately.