Tel/WhatsApp

Tel/WhatsApp

Pyrolysis refers to the reaction process in which a substance is decomposed by heat, that is, thermal decomposition, and serves a main purpose: transforming waste into valuable resources while mitigating environmental harm. Nowadays, grappling with overflowing landfills, depleting fossil fuels, and climate change, pyrolysis is more and more widely applied in the waste treatment for its high efficiency and good economic performance. Here’s how this process achieves its goals, with a focus on how DOING pyrolysis machines amplify these benefits.

一.Convert Waste into High-Value Products

Pyrolysis is primarily used in the petrochemical industry to extract various fuel oils from crude oil. It converts valuable or hazardous waste, such as scrap tires, waste plastics, and oil sludge, into marketable resources through pyrolysis, reducing dependence on virgin materials and fossil fuels. Key outputs include:

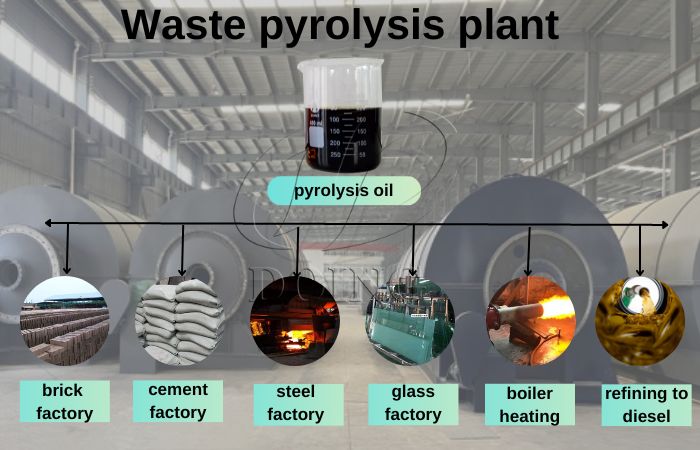

1.Pyrolysis oil: It is widely used as a liquid fuel for boilers, industrial plants (gypsum plants, brick plants, cement plants, steel mills, glass plants), and heavy oil generators, replacing petroleum-based fuels. It can be also further refined into diesel like fuel oil and used for diesel generator and heavy machinery (trucks, ships, tractors) etc..

(Thanks to the multi-stage condensation and patented catalysts used in DOING pyrolysis machines, the oil yield from scrap rubber tires reaches 45%, and from plastics reaches 90%.)

Pyrolysis oil application

Pyrolysis oil application

2.Pyrolysis carbon black: It is used as a solid fuel; it can be used for modified liquid fuel production, as a sorbent, activated coal substitution, as a filling material for production of new low-duty rubber goods, as a colorant for paints and colors, cement and other productions, as a filling material for rubber-bituminous mastic and as a substance for disposal of mercury-containing materials (of bulbs, etc.).

3.Flammable syngas: It is used as heating fuel for pyrolysis process and can be stored as well for other kind of heating purpose.

二.Solve Waste Management Crises

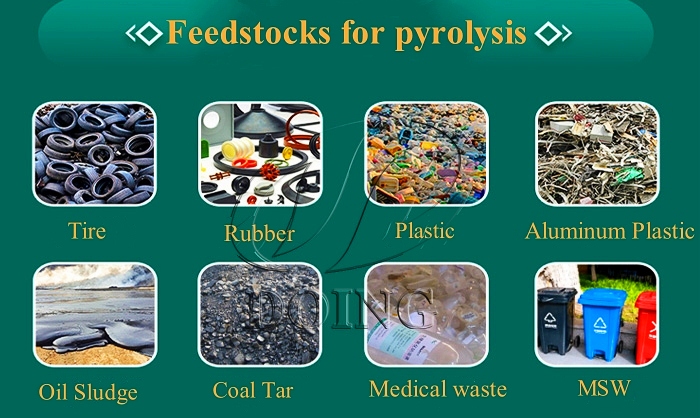

Traditional waste disposal methods (landfills, incineration) are unsustainable: landfills leak toxins into soil and water, while incineration releases greenhouse gases. DOING pyrolysis machines can process a variety of wastes, especially those that are difficult to mechanically recycle, such as:

Raw materials that can be recovered by pyrolysis

Raw materials that can be recovered by pyrolysis

1.Mixed plastics (which cannot be recycled through traditional methods);

2.Waste tires and rubber waste (which take 80–100 years to decompose in landfills).

3.Hazardous waste (medical waste, waste oil sludge);

4.Biomass (agricultural residues, wood waste)

三.Reduce Environmental Impact

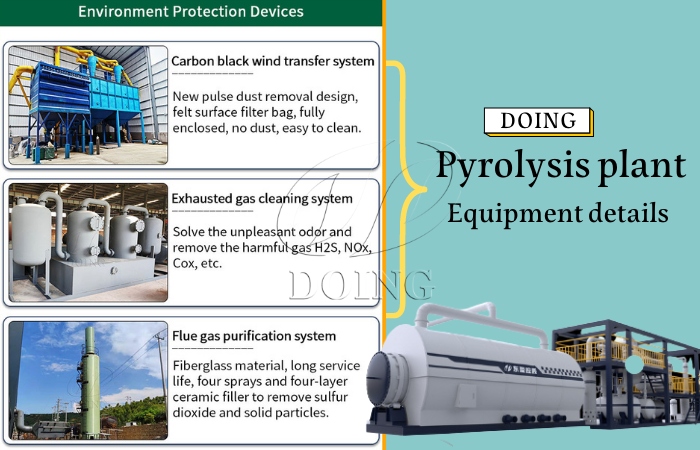

By avoiding incineration (which emits CO₂ and toxic pollutants) and landfill use, pyrolysis cuts carbon footprints and reduces pollution. Modern systems like DOING include advanced filtration to minimize emissions:

1.DOING exhaust gas purification unit: It treats excess, non-condensable, and non-storable combustion gases to reduce emissions.

2.DOING desulfurization tower: It removes harmful substances such as hydrogen sulfide, nitrogen oxides, and sulfur oxides, as well as irritating odors, to prevent acid rain.

3.DOING carbon black containment system: It seals and collects carbon black, preventing it from leaking and contaminating the environment.

4.DOING circulating water system: It ensures no wastewater is generated.

Pyrolysis machine environmental benefits

Pyrolysis machine environmental benefits

The main purpose of pyrolysis is to transform waste materials into valuable products, contributing to energy generation and environmental sustainability. DOING pyrolysis machines are designed to carry out this process efficiently, providing businesses with a reliable and eco-friendly solution for waste management. We have been committed to waste recycling through pyrolysis in more than 14 years, more questions about pyrolysis, please feel free to inquire us.