Tel/WhatsApp

Tel/WhatsApp

In cities and regions around the world, a stubborn reality remains: large volumes of waste plastics are still ending up in landfills rather than being reused or recycled. While seemingly a straightforward plastic treatment method, this practice is not only an environmental burden but also a substantial missed economic opportunity.

Waste plastic treatment by landfill

Waste plastic treatment by landfill

From the United States and Germany to India, Brazil, Indonesia, United States, China, Philippines, Malaysia, Australia, South Africa, Nigeria, and some Europe countries, the diversion of plastics from waste streams is not keeping pace with production. When this material is buried, its inherent value is effectively lost forever. This translates into direct costs for municipalities and private sector waste handlers, as well as opportunity costs for manufacturers and processors who could otherwise convert plastics into valuable products.

However, embracing circular economy principles through advanced recycling pyrolysis technologies presents a compelling alternative, offering a pathway to both environmental stewardship and robust profitability. Waste plastic isn't just a problem or inert waste, this valuable feedstock, composed of polymers with significant energy potential, could be transformed into lucrative products.

Waste plastic pyrolysis machine

Waste plastic pyrolysis machine

Potential of Recycling Waste Plastic Through Pyrolysis Machine

Pyrolysis technologies—often knowns as cracking or thermal decomposition—turn waste plastic disposal cost into a production line with multiple revenue. These processes heat scrap plastics in the absence of oxygen, breaking long polymer chains into smaller hydrocarbons.

Instead of paying to landfill, pyrolysis machine can turn waste plastic into valuable byproducts:

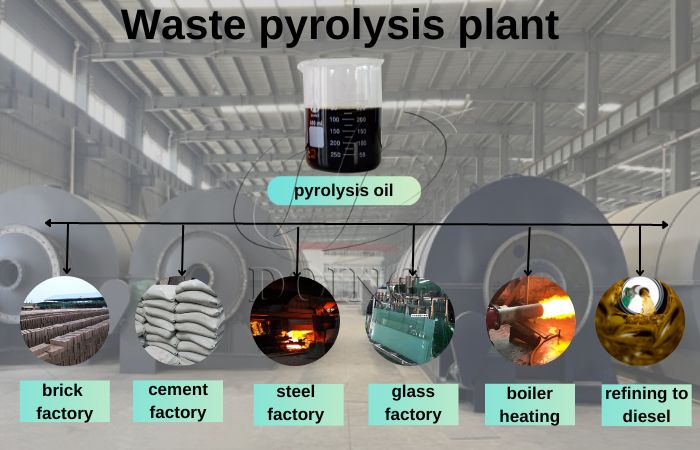

High-Calorific Industrial Fuel: The Plastic Pyrolysis Fuel Oil(PPO) produced through pyrolysis machines boasts a high calorific value, approximately 9,679 to 11,428.5 kCal/kg (or 40.5 to 47.8 MJ/kg), which is similar to conventional fuels like gasoline and diesel. It making it an excellent and cost-effective alternative to conventional industrial fuels. This can significantly reduce operational costs for manufacturing plants, power generators, and other heavy industries. Plastic pyrolysis oil prices range from about $600 to $1000 per ton.

Pyrolysis plastic into fuel oil with wide applications

Pyrolysis plastic into fuel oil with wide applications

High-Quality Carbon Black: Pyrolysis also yields carbon black, a crucial component in the production of tires, inks, and various rubber products. By producing carbon black domestically from waste, regions can reduce their reliance on imports and create a more sustainable supply chain.pyrolysis carbon black prices vary significantly by grade and market, prices from $450 to over $800 per ton.

Combustible Gases: The process generates a syngas mixture that can be used as an energy source, further enhancing the overall efficiency and economic viability of the operation. It also reduce the operation cost of waste plastic to fuel oil pyrolysis machine.

The economic argument is undeniable. By implementing a pyrolysis solution, you are not only mitigating the environmental impact of plastic waste but also actively generating revenue from materials that would otherwise be a cost. This is a market opportunity that is rapidly expanding, particularly in areas with high plastic waste generation, such as densely populated countries in South America or island nations like those in Oceania struggling with waste management.

DOING Company Expertise: Turning Waste Plastic Waste into Profit

As an experienced manufacturer of pyrolysis machine, we understand the nuances of turning plastic waste into a valuable commodity. We have developed efficient pyrolysis systems capable of processing a wide array of plastic feedstocks, including:

Commonly Recycled Plastics: HDPE, LDPE, PP, PE, PS, ABS

Mixed Plastic Waste: Challenging streams that are often sent to landfill, such as municipal solid waste, medical waste, agricultural waste like plastic films, construction waste such as woven bags

Composite Plastics: Materials often considered difficult to recycle through conventional mechanical means, such as plastic aluminum composite materials.

We have partnered with clients in various regions to implement reliable and profitable plastic recycling solutions. And to meet different customers waste plastic disposal and recycling requirements, we have developed different types of pyrolysis machines: Four types of waste plastic pyrolysis machines for sale

Four types of waste plastic pyrolysis machines for sale

Skid-Mounted Type: Easy for Transportation, Movement, and Installation, Start From 100KG Per Batch

Batch Type: Relatively Low Cost, Generally Process 1-15Ton Plastic Scrap Per Batch

Semi-Continuous Type: Cost-Effective, 5-20Ton DailyCapacity, Higher Efficiency than Batch Type

Fully-Automatic Type: Intelligent Controlled, 24/7 Hours Running, Highest Automation Degree, Most Profitable, 15-50Ton Waste Plastic Processing Volume Per Set

Don't let your waste plastic become a hidden liability. Ready to learn more about how DOING Brand pyrolysis machine solutions can benefit your organization and generate substantial profits from waste plastic? Contact us today to discuss your specific needs and explore this exciting market opportunity.