Tel/WhatsApp

Tel/WhatsApp

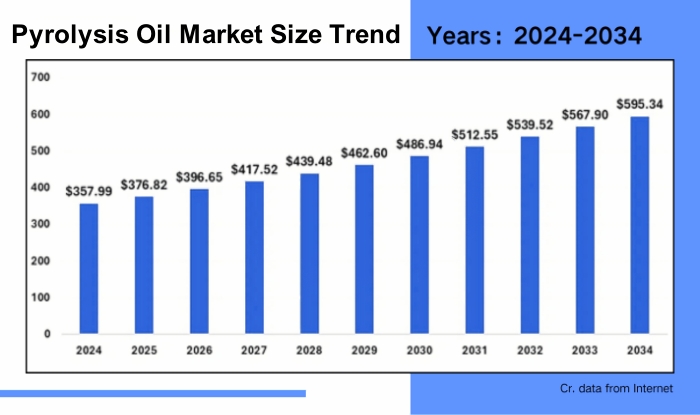

The pyrolysis oil market has been attracting significant attention in recent years. As far as we know, waste tire/platsic to heating fuel oil pyrolysis machine is more and more popular, The pyrolysis oil market is set to grow at an estimated CAGR of 8.6% from 2025 to 2034, rising from $1.1 billion in 2024 to $2.5 billion by 2034. There are many factors driving the growth of the pyrolysis oil market. I will introduce them to you in details.

Affecting the pyrolysis oil market factors

Affecting the pyrolysis oil market factors

1.Environmental Regulations:

Many countries, such as the United States, China, India, France, the Netherlands, Malaysia, Japan, Brazil, Germany, the United Kingdom, etc., encourage pyrolysis oil production to reduce landfill and carbon emissions. Data shows that pyrolysis oil extracted from waste tires emits 2.2 kg of CO2/kg, which is much lower than the emission of traditional carbon black production of 3.5 kg of CO2/kg.

DOING pyrolysis machine environmental system

DOING pyrolysis machine environmental system

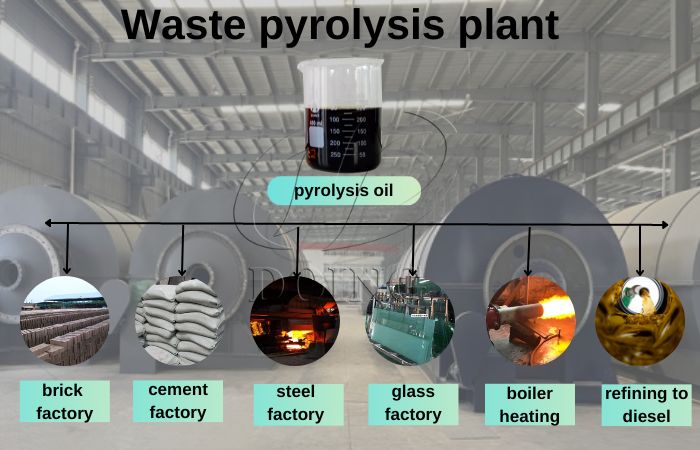

2.Diverse Applications of Pyrolysis Oil:

The main application of pyrolysis oil is as an alternative fuel. The calorific value of pyrolysis oil is 15-25 MJ/kg, which is comparable to the calorific value of coal at 20 MJ/kg, and the price is more favorable than petroleum-based fuels. It is applicable in multiple industries such as ceramic factories, boiler factories, construction heating, steel factories, glass factories, cement factories, power plants, boiler factories, gypsum factories. Additionally, it can be used as a feedstock for refining diesel fuel. After being refined into diesel by a distillation machine, the obtained diesel can be used in machinery like trucks, tractors, ships, and diesel generators.

Application of pyrolysis oil

Application of pyrolysis oil

3.Demand of Pyrolysis oil Growth:

Bioenergy is expected to play a crucial role in future energy structures, particularly in the oil and gas markets, which will drive up demand for pyrolysis oil. Here is pyrolysis oil market trend chart.

Pyrolysis oil markert size trend

Pyrolysis oil markert size trend

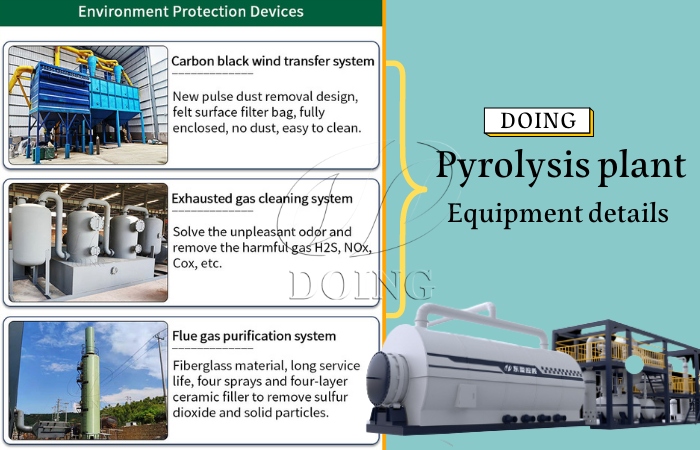

4.Pyrolysis Technological Progress:

Innovations have improved the efficiency and oil yield of the pyrolysis process, this has made pyrolysis oil production more cost-effective and commercially viable, attracting more investments and interest from industries and governments.

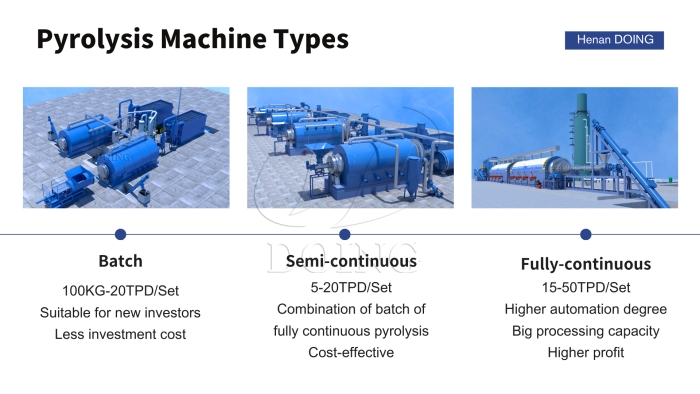

DOING waste recycling pyrolysis machines

DOING waste recycling pyrolysis machines

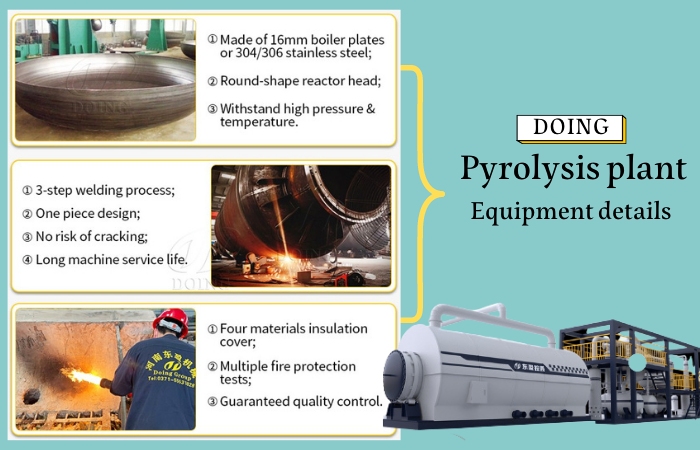

As the demand for pyrolysis oil grows, investing in a high-quality pyrolysis machine becomes essential. DOING, a leading manufacturer of waste recycling pyrolysis machines, offers cutting-edge technology designed for high efficiency and sustainability. DOING waste pyrolysis machines convert waste materials, including tyres, plastics, rubbers, oil sludge into valuable pyrolysis oil, carbon black, steel wire, and gas. Our machines feature advanced technology, stable performance, and high oil yield, providing reliable solutions for waste recycling and pyrolysis oil production.

DOING waste recycling pyrolysis machines advantages

DOING waste recycling pyrolysis machines advantages

DOING waste pyrolysis machine has numerous advantages. It adopts a unique heating system and reaction design to ensure uniform heating of waste, efficient pyrolysis, and high waste conversion rate. The machine also incorporates effective gas purification and environmental protection devices to minimize emissions and meet strict environmental standards. Additionally, our machines are designed for easy operation and maintenance, with high automation and safety levels, reducing labor intensity and operational costs for users.

In summary, the pyrolysis oil market is expected to grow significantly in the future, driven by the demand for renewable energy, waste management challenges, and technological advancements. Investing in advanced pyrolysis machine, such as DOING machines, is a smart choice for companies looking to enter this growing market. Welcome to contact us.