Tel/WhatsApp

Tel/WhatsApp

Waste oil, typically generated from automotive engines, industrial processes, which is composed of hydrocarbon polymers. There are multiple wasteoilrecyclingways, each with its own advantages and limitations. Sedimentation separation relies on gravity to allow heavier impurities to settle at the bottom, but it may not effectively remove fine particles. Filtration uses physical barriers to trap contaminants, yet it might not be sufficient for complex waste oil mixtures. Centrifugal separation employs centrifugal force to separate components based on density differences. Biological treatment utilizes microorganisms to break down organic matter in waste oil, but it may require specific conditions and time. Compared with the above waste oil recycling ways, distillation and refining plant stands out as a highly efficient recycling way.

Waste oil recycling way

Waste oil recycling way

As a leading manufacturer of waste oil distillation and refining plant, DOING provides an eco-friendly and efficient solution through advanced distillation and refining technology. DOING waste oil distillation and refining plant just works to recycle waste oil into diesel fuel. It has different model and oil handling capacity, such as 1/3/5/7/10/14ton, among which our 10 ton latest waste oil distillation and refining plant is most popular with our customers. Here’s how it works and why our equipment stands out.

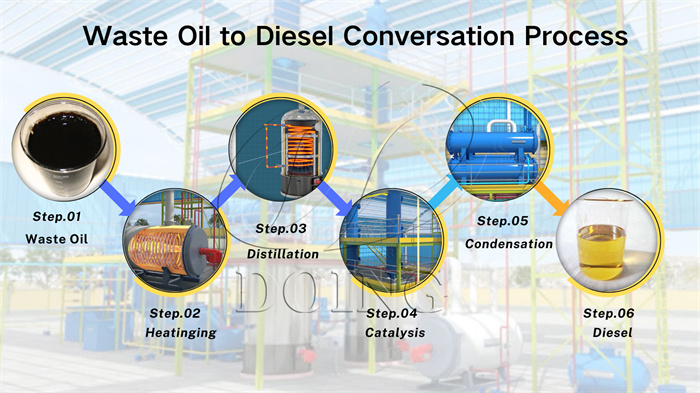

The recycling process of DOING waste oil distillation and refining plant.

1.Heating the waste oil:

Using DOING waste oil distillation plant, waste oil is heated to a high temperature so that its components are separated into oil and gas according to the boiling point. This initial step is crucial in the distillation process.

2.Catalytic refining of waste oil

The oil and gas generated by heating are purified by the combined action of two catalysts patented by DOING. This catalytic refining step ensures the quality of the final product.

Waste oil distillation and refining plant process

Waste oil distillation and refining plant process

3.Cooling of waste oil and gas

The distilled oil gas after catalytic treatment are condensed into oil through the DOING cooling system and then collected in a temporary oil tank, ready for further processing or use.

4.Further decolorization of the oil

To ensure the final product is suitable for use in heavy machinery and engines, the cooled oil is further decolorized using white clay. This process ensures that the final product gets lighter color.

The advantages of DOING latest waste oil distillation and refining plant

1.Multi-Oil Compatibility:

Processes hydraulic oil, pyrolysis oil (crude oil), used motor oil, used engine oil, used lube oil, liquid oil sludge and more.

2.High Diesel Yield:

Adopting DOING patented dual catalyst, the waste oil recovery rate is more than 85%, ensuring minimal waste and maximum output.

3.Low Energy Consumption:

The dual heating system can quickly heat up the DOING waste oil distillation and refining plant reactor, which can reduce operating costs.

Dual heating system of DOING waste oil distillation and refining plant

Dual heating system of DOING waste oil distillation and refining plant

4.Reliability and Safety:

DOING waste oil distillation and refining plant is equipped with multiple safety features and undergoes strict quality control. It operates smoothly with minimal downtime, ensuring consistent production and peace of mind for our customers.

5.Customization:

We understand that different customers have different needs. That's why we offer customized solutions, including different models and capacities of waste oil distillation and refining plant to suit your specific business requirements.

6.Environmental:

Less waste liquid and waste residue are generated, and secondary pollution is low.

To sum up, the recommended waste oil recycling way is to use DOING waste oil distillation and refining plant. If you have any questions or want to know more about DOING waste oil process and recycling way, please feel free to contact us.