Tel/WhatsApp

Tel/WhatsApp

According to industry reports, Indonesia discards millions of used tires annually. For investors looking to make a meaningful impact while capitalizing on a lucrative opportunity, setting up a tire pyrolysis plant in Indonesia is an excellent choice.

Here are favorable conditions for establishing a tire recycling pyrolysis plant in Indonesia:

1. Abundant waste tires supply and enery demand

Large output of waste tires: Indonesia is one of the world's largest producers of used tires, with a large number of motorcycles and cars, and produces a large number of waste tires every year, providing sufficient raw materials for pyrolysis plants.

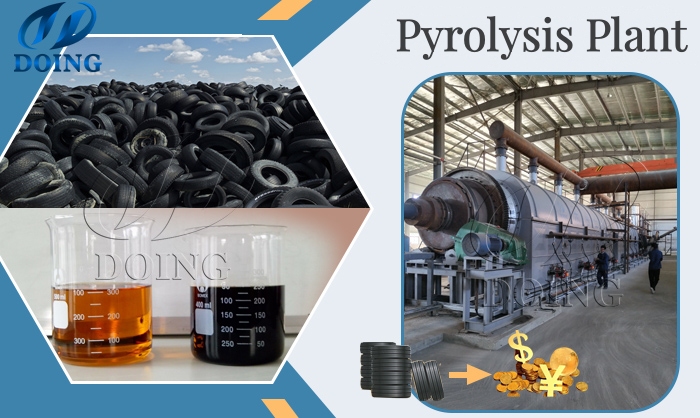

Waste tire recycling pyrolysis in Indonesia

Waste tire recycling pyrolysis in Indonesia

Growing energy demand: Southeast Asia's economy is developing rapidly, and the demand for energy continues to rise. Products produced by tire recycling pyrolysis plants have great aopplications to meet the increasing energy demand in the market:

Pyrolysis oil: can be used as alternative fuels to meet part of the energy demand, and the market prospects are broad.

Recycled carbon black: can be used in various industries, such as rubber manufacturing, plastics, and even as a pigment in paints and coatings.

Steel wires: can be extracted and recycled, contributing to the production of high-quality steel.

Gas: The process also generates combustible gas, which can be used to power the plant, making the system energy-efficient and self-sustaining.

2. Positive policy suppot

On the one hand, the Indonesian government promotes green economy and circular economy policies, encourages the resource utilization of waste, and supports tire recycling projects, including simplifying procedures and reducing environmental protection equipment requirements, which can effectively save investment costs.

On the other hand, the government has set a goal of reducing waste generation by 20% by 2030, which has promoted the development of multiple waste recycling plans and provided policy motivation for the construction of tire recycling pyrolysis plants.

Waste tire recycling pyrolysis technology benefits

Waste tire recycling pyrolysis technology benefits

3. Strategic Location

Indonesia's geographical position in Southeast Asia provides easy access to raw materials and a large market for recycled products. The country's vast archipelago allows for efficient transportation of materials, while its growing economy provides a ready market for recycled products like fuel oil, carbon black, steel, etc.

And compared with developed countries, Indonesia's land cost is relatively low, which provides a broader space for the construction and operation of the factory and reduces the investment cost of the project.

4. Mature pyrolysis technology

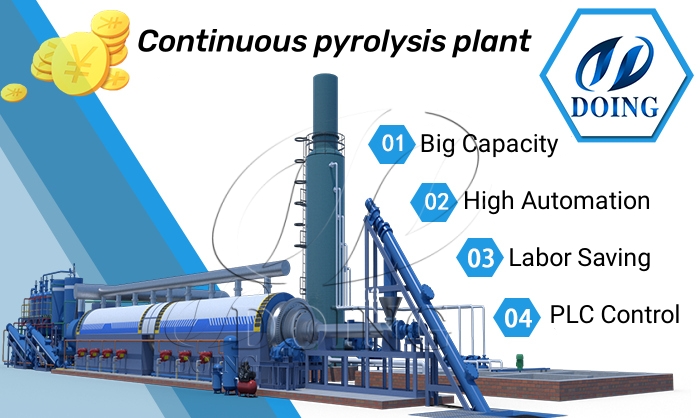

In the past decade, tire pyrolysis technology has been continuously updated. The new tire recycling pyrolysis machine has been greatly improved in efficiency, environmental protection, and automation, providing more reliable technical support for the implementation of the project.

There are already various types and different capacities of waste tire recycling pyrolysis machines available in the market, suitable for different investment scales. For instance, the latest 50-ton continuous tire recycling pyrolysis technology have been commercialized, facilitating rapid deployment.

Advanced continuous tire recycling pyrolysis machine advantages

Advanced continuous tire recycling pyrolysis machine advantages

In conclusion, establishing a tire recycling pyrolysis plant in Indonesia not only aligns with local policy directions but also fully utilizes the existing market demand, technical support, and investment environment, making it highly feasible and promising for development.

How DOING help you install tire recycling pyrolysis plant in Indonesia?

At DOING, we are proud to offer state-of-the-art waste tire pyrolysis equipment designed to meet the highest standards of efficiency, safety and environmental protection. Our equipment has been exported to 100 countries and regions around the world, including Indonesia, earning us a reputation for high quality and reliability.

A. Proven tire recycling pyrolysis technology

Our waste tire recycling pyrolysis plants offer advanced continuous, semi-continuous and batch pyrolysis machine technology. They use a unique reactor design to ensure uniform heating and optimal decomposition of waste tires, thereby maximizing the output of valuable products.

Batch continuous tire recycling pyrolysis machines for sale in Indonesia

Batch continuous tire recycling pyrolysis machines for sale in Indonesia

After years of research and development, we continue to improve our technology to reduce energy consumption and minimize emissions, making our plants fully compliant with international environmental standards.

B. Installation and commissioning expertise

We not only sell tire recycling pyrolysis machines, but also provide comprehensive support throughout the project life cycle. Customer satisfaction is the core of our business.

Top tire recycling pyrolysis machine manufacturer services

Top tire recycling pyrolysis machine manufacturer services

We have a professional installation team that can provide fast and efficient equipment solution customization, installation and commissioning services to customers in Indonesia, and optimize and adjust according to local actual conditions to ensure that the pyrolysis equipment is put into operation smoothly. At the same time, we also provide training and technical support to help customers master the operation and maintenance skills of the equipment to ensure the long-term and stable operation of the tire recycling pyrolysis plant.