Tel/WhatsApp

Tel/WhatsApp

Waste plastic pyrolysis plant

When the temperature reaches about 250-280℃, there will be oil gas generating. Then the oil gas will be cooling down by the condenser, it would be liquefied and go into the oil tank. While the gas which can’t be liquefied under the normal pressure will be designed to go back to combustion system through safety device. And the combustible gas can be recycled to heat the reactor as fuel, which will save energy for the whole waste plastic pyrolysis working process.

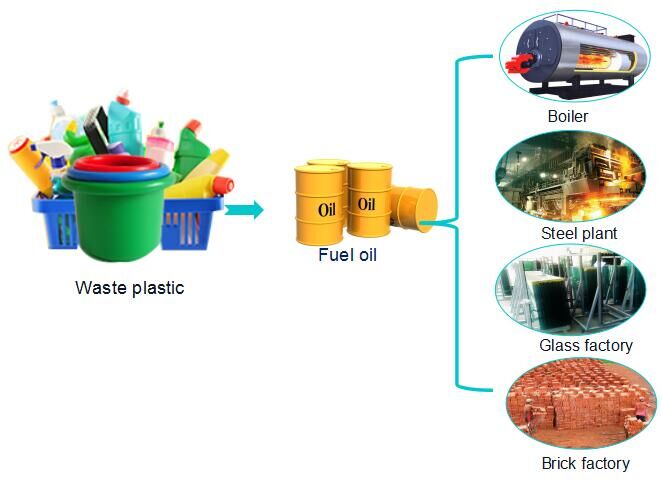

Fuel oil application

Through the whole waste plastic pyrolysis plant process, plastic scrap can be effectively turned into two useful resources, such as plastic oil and carbon black. Both of the end-products can be used as fuels for burning. In addition, the oil also can be further refined to diesel or gasoline and the carbon black can be used for construction bricks with clay. They are both in high demand and fetch good prices in the market, which will surely get your cost back soon and bring you great benefits.