Tel/WhatsApp

Tel/WhatsApp

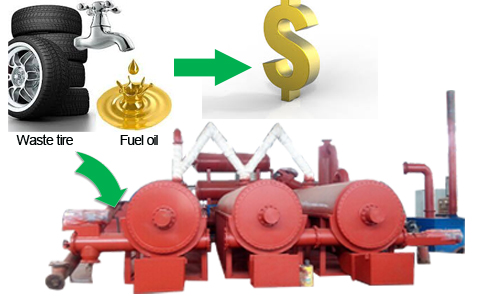

Waste tyre pyrolysis process plant

Pyrolysis refers to a thermochemical decomposition of organic material at elevated temperatures in the absence of oxygen. Through the use of Doing tyre pyrolysis plant, waste tyres can be effectively turned into tyre oil, carbon black and steel wire. The following is a brief description of the waste tyre pyrolysis process :

Waste tyre pyrolysis process

(1) Put the waste tyres into reactor and make reactor rotate clockwise 0.4-0.8 r/min. Seal the feeding inlet door tightly and make sure there is no gas leakage.

(2) Heat the reactor by using coal, charcoal, fuel gas, wood etc. as heating materials. The reactor will be slowly heated, and when the temperature reach about 250℃, the oil gas will be formed.

(3) The oil gas coming out from the reactor then goes to condensing system and become liquid oil. The gas which can’t be liquefied under normal pressure will be designed to go back to combustion system through safety device. It can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

(4) After finishing oil production, the temperature of the reactor will fall down, when the temperature falls down to 40℃, we can get carbon black and steel wire.