Tel/WhatsApp

Tel/WhatsApp

Conversion of plastic to fuel oil

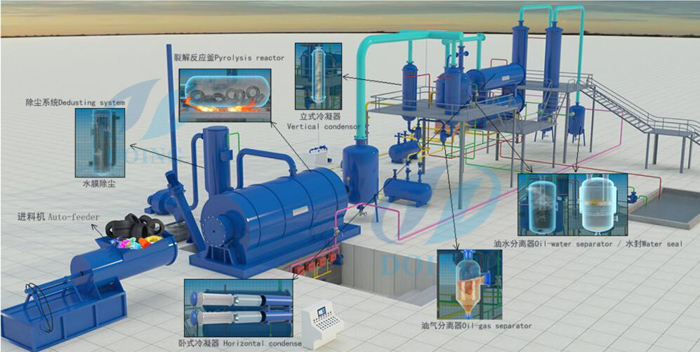

The conversion of plastic to fuel machine are designed to turn waste plastics into pyrolysis oil and carbon black. As a professional manufacturer of conversion of plastic to fuel oil , Doing group conversion of plastic to fuel oil with the special design and good performance, which make them become more and more popular in the domestic and foreign markets.

Conversion of plastic to fuel oil process

Conversion of plastic to fuel oil working process

1) Put the waste tyre/plastic into reactor and make reactor rotate clockwise 0.4-0.8 r/min. Seal the feeding inlet door tightly and make sure there is no gas leakage.

(2) Heat the reactor by using coal, charcoal, fuel gas, wood etc. as heating materials. The reactor will be slowly heated, and when the temperature reach about 250 degrees, the oil gas will be formed.

(3) The oil gas coming out from the reactor then goes to condensing system and become liquid oil. The gas which can’t be liquefied under normal pressure will be designed to go back to combustion system through safety device. It can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

Fuel oil application

(5) After finishing oil production, the temperature of pyrolysis reactor will fall down, when the temperature falls down to 40 degrees Celsius, we can get carbon black .