Tel/WhatsApp

Tel/WhatsApp

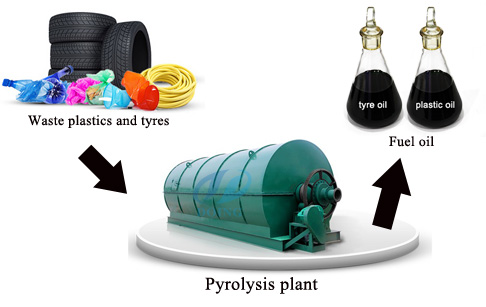

Pyrolysis plant

Pyrolisis plant to extract fuel from recycle waste is a machine that converts waste plastic,tyres and rubber and other waste materials into pyrolysis oil, carbon black and hydrocarbon gas. The pyrolisis plant to extract fuel from recycle waste can reduce the volumes of the waste products and help human protect the environment.

The business uses wastes like tires, rubber, plastic, oil sludge, medical waste, as well as the plastic. The method involves subjecting the plastic waste with a high temperature which can be between 400 and 450 degrees Celsius. In the process, there is absolutely no oxygen used. The reason behind that is to avoid plastic from burning.

When Pyrolysis,the plastic/tire/rubber is categorised into smaller molecules that include the particles of Pyrolysis oil, gas and carbon black.