Tel/WhatsApp

Tel/WhatsApp

Waste tires pose severe environmental risks—from fire hazards in landfills to toxic pollution from improper disposal. There are many technologies for recycling tires, improper tire disposal is illegal in many municipalities, so it takes a tire recycling business to safely handle, store and transport used tires and learn the basics of tire recycling.

Here are the tire recycling methods:

1. Retreading:

Retreading is a technology that uses professional techniques to repair worn or slightly damaged tire carcasses and re-vulcanize the tread to restore its performance. Waste tires can usually only be retreaded once, and commercial vehicle tires can be retreaded at most 2-3 times, and the product is a reusable tire. Adhesives, vulcanizers and other chemicals are used in the tire retreading process. If not handled properly, VOCs (volatile organic compounds) may be released.

Tire recycling method: retreading

Tire recycling method: retreading

2. Shredding:

Shredding refers to the process of using professional equipment to process waste tires into rubber piece. Equipment will vary, depending upon what you plan on doing, but may include everything from bead removers and tread cutters to shredders. The products are rubber powder and steel wire. Rubber powder is used to modify asphalt, rubber floor tiles, floor mats, runways, playground floors, waterproof materials, etc. Steel wire can be directly sent to steel mills as scrap steel raw materials for smelting and used to produce new steel or after further processing that be made into simple metal products such as binding wire, wire mesh, nails, hooks, etc. Rubber dust will be generated during the crushing process, which will pollute the air if not collected properly. If the rubber powder is piled in the open air, it may release microplastics due to rainwash, polluting the soil and water.

Tire recycling method: shredding

Tire recycling method: shredding

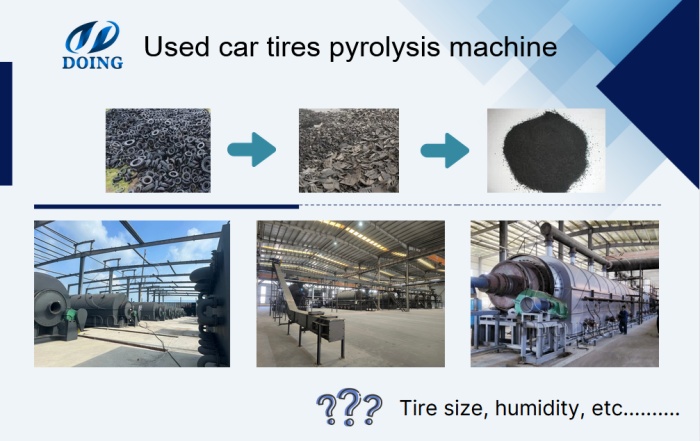

3.Pyrolysis:

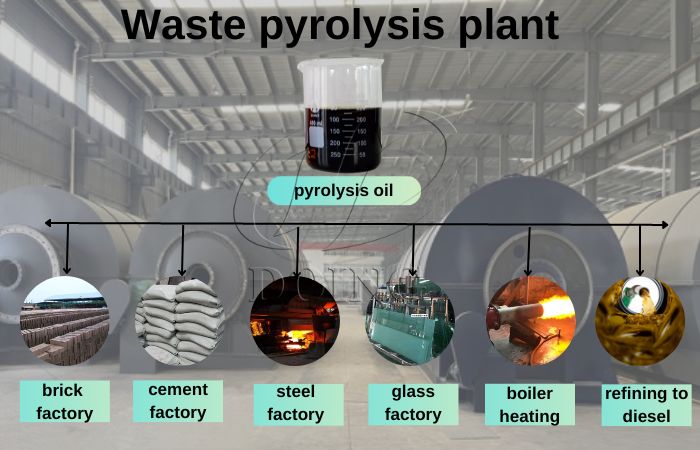

Pyrolysis is a technology that can process all types of waste tires in an oxygen-free and high-temperature state, including scrap tires that cannot be retreaded, tires with severely damaged carcasses, and even scraps from the tire production process. The products are carbon black, syngas, fuel oil that replaces fossil fuels. Fuel oil used for industrial boilers, generators, or refineries. Carbon black used for rubber manufacturing or pigment production. Steel wire used for recycling into new steel products or after further processing.

Tire recycling method: pyrolysis

Tire recycling method: pyrolysis

Compared with shredding and retreading, pyrolysis has stronger compatibility with waste tires, more thorough resource conversion, higher product added value, and better environmental controllability. Recently years, pyrolysis technology has been continuously developed, from pyrolysis machine to the final product. Starting a tire pyrolysis recycling business is a promising venture that combines environmental benefits with profitable returns, especially with the right equipment like DOING waste tire recycling pyrolysis machines. Here’s a step-by-step guide to help you launch successfully.

1.Create a preliminary business plan

First, check national and local prices for tires and crumb rubber and analyze local demand for recycled tire products. Pyrolysis-derived products (pyrolysis oil, carbon black, steel wire) are in high demand in industries like energy, construction, and manufacturing. Identify your target customers—such as industrial boiler operators, steel mills or fuel distributors.

Application of tire pyrolysis oil

Application of tire pyrolysis oil

A business license and proper zoning for your location is only part of the approval process. Research local environmental laws, waste handling licenses, and emissions standards. A tire recycling business may require specific permits or licenses, depending upon the location. In Texas, for example, all facilities storing more than 500 tires must be registered with the Texas Commission on Environmental Quality (TCEQ). Some permits will cost a significant amount of money. Don't forget to include those figures in your final business plan. Some cities also have tire cleanup days or tire amnesty days, which give subsidies to organizations that collect tires.

3.Secure Suitable Premises

Find a location that meets the requirements for waste processing. It should have sufficient space for equipment installation, raw material storage, and product handling. Ensure the site complies with local environmental and safety regulations. The area of the DOING waste tire recycling pyrolysis machine is about 300 to 700 square meters.

DOING tire recycling pyrolysis machine

DOING tire recycling pyrolysis machine

4.Locate tire sources

Your local waste management department will most likely have the most up-to-date information about tire waste in your area. It is important to make connections with local businesses that receive scrap tires. Scrap tires may come from local mechanics, department stores with tire departments or auto dealer or junkyards.

5.Choose the Right Equipment

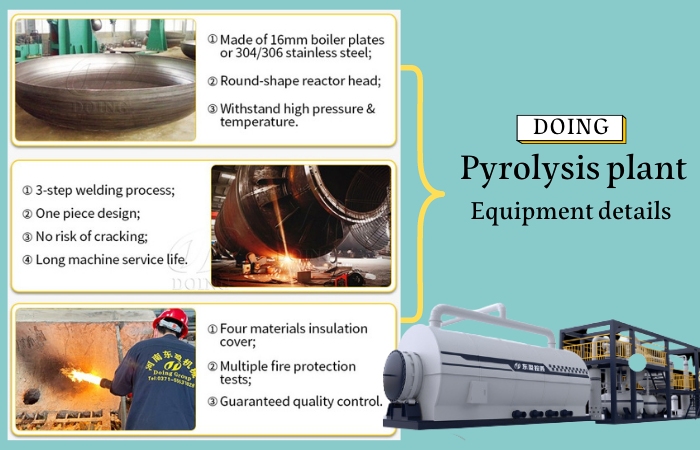

Investing in reliable pyrolysis equipment is critical. DOING waste tire recycling pyrolysis machines stand out with:

DOING tire recycling pyrolysis machine advantages

DOING tire recycling pyrolysis machine advantages

① High Efficiency: 40-45% oil yield from waste tires, with 10 tons of tires producing 4-4.5 tons of pyrolysis oil (usable as industrial fuel). The multi-stage condensation of the cooling system can recover 100% of the oil and gas and reduce waste.

② High quality: DOING waste tire recycling pyrolysis equipment is made of durable materials such as Q245R and Q345R, and can also be customized with stainless steel to ensure long-term stability and corrosion resistance.

③Safe and environmentally friendly: DOING advanced sealing technology prevents gas leakage. The carbon black air transport system seals and collects carbon black to prevent dust leakage and protect the environment in the workshop. DOING waste tire recycling pyrolysis machine uses a circulating water system, does not produce wastewater, and can also customize environmental protection devices (like desulfurization towers and exhaust gas purifiers) to ensure your pyrolysis plant meets air and water pollution control requirements and help you pass local EIA inspections smoothly.

④Comprehensive system: From tire pretreatment equipment to carbon black collection device, ensure seamless connection from tire to final product.:

⑤A variety of types of equipment for you to choose: frame type/batch type/semi-continuous type/full-continuous type/can be customized according to your requirements and budget.

DOING tire recycling pyrolysis machine types

DOING tire recycling pyrolysis machine types

6. Train Staff and Launch

Ensure operators are trained to use DOING waste tire recycling pyrolysis machine for safe, efficient operation. With proper training, your team can monitor temperatures, adjust settings, and troubleshoot easily, minimizing downtime and improving operational efficiency.

DOING guidance on setting up tire pyrolysis business

DOING guidance on setting up tire pyrolysis business

Starting a tire recycling business offers a profitable venture, so it is requires careful planning, the right equipment, and effective management. Partnering with DOING, a supplier of efficient, safe and environmentally friendly waste tire recycling pyrolysis machines, is an ideal choice for tire recycling industry practitioners. If you are interested in learning more about our pyrolysis machines or need guidance on starting your tire recycling business, feel free to contact us. We are here to help you every step of the way.