Tel/WhatsApp

Tel/WhatsApp

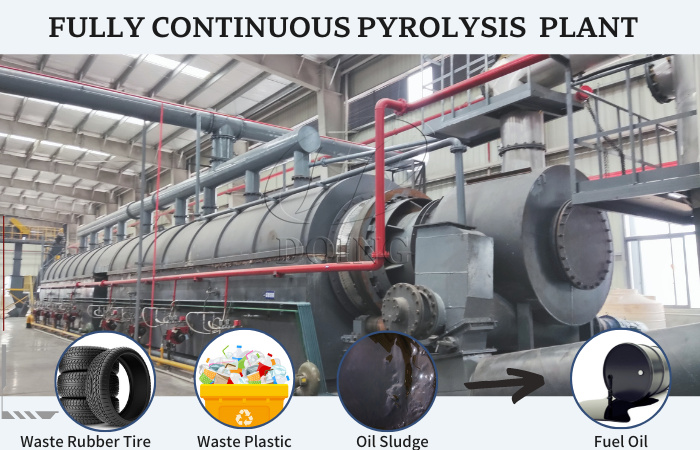

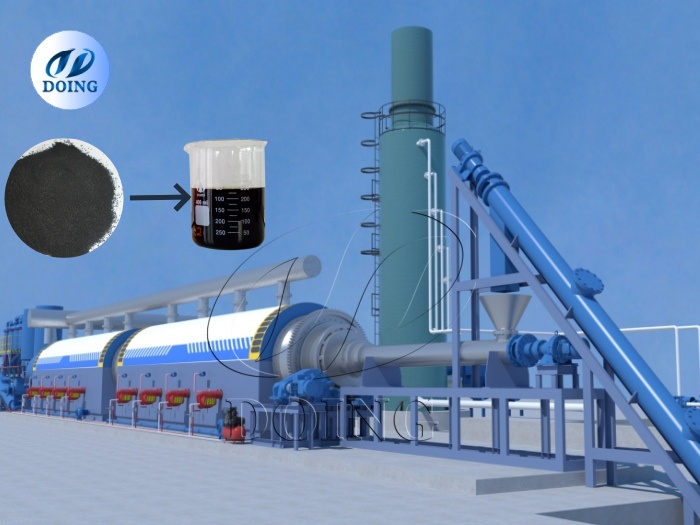

As global waste volumes surge, fully automated pyrolysis systems are revolutionizing recycling by converting plastics, tires, and oil sludge into value fuel and residue. Investing in fully automated pyrolysis systems holds great potential for waste management, resource recovery, and energy production. Nevertheless, like all major investments, it has its own set of advantages and disadvantages. Here’s an introduction from DOING :

DOING fully-continuous pyrolysis syste

DOING fully-continuous pyrolysis syste

Pros of fully automated pyrolysis system:

1.Enhanced Efficiency.

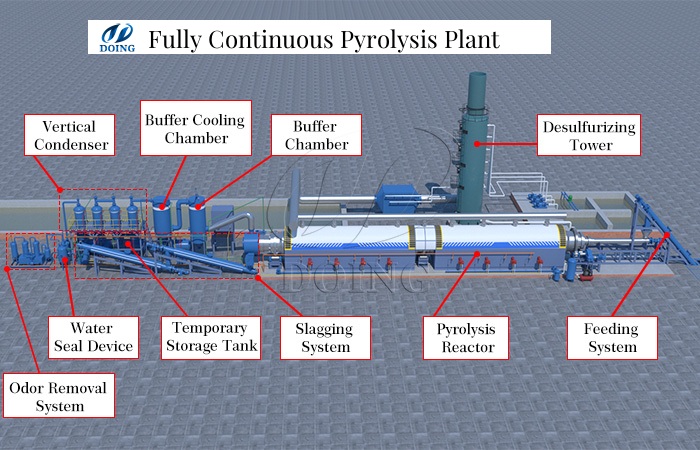

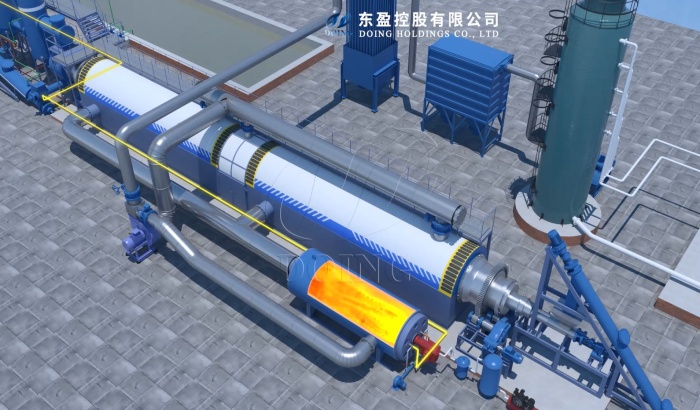

Continuous operation: The fully automated pyrolysis system has a single processing capacity of 15-50+TPD, it can run non-stop around the clock for 45 days, with continuous feeding and continuous slag discharge, without waiting for the residue to cool, which significantly improves throughput and productivity, allowing more waste to be processed in a shorter time.

Optimized Process Control: Precise control over temperature, pressure, and feed rate ensures optimal conditions for maximizing product yields and improving quality.

DOING fully automated pyrolysis system

DOING fully automated pyrolysis system

2.Improved Safety.

Reduced Human Intervention: Fully automated pyrolysis system equip PLC control system, minimizing human interaction with machinery reduces the risk of workplace accidents. Fully automated pyrolysis system handle hazardous materials safely and efficiently.

Emergency Shutdowns: Advanced safety features such as automatic shutdown mechanisms in case of malfunction protect both personnel and equipment.

PLC system of DOING fully automated pyrolysis system

PLC system of DOING fully automated pyrolysis system

3.Environmental Benefits.

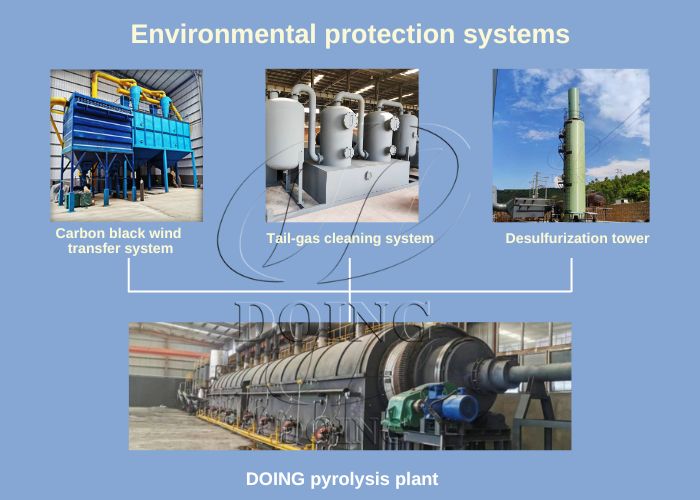

Efficient emission management: Modern automated systems minimize exhaust emissions through exhaust gas purification devices and tail gas purification devices, thereby reducing environmental impact. Meet emission standards in the United States, Spain, Belgium, Europe and the other countries.

Environmental protection system of fully automated pyrolysis system

Environmental protection system of fully automated pyrolysis system

4.Cost Savings in the Long Run.

Lower Operational Costs: While initial investments may be high, reduced labor costs, improved efficiency, and lower maintenance requirements contribute to long-term savings.

Energy Efficiency: Many fully automated pyrolysis system use energy recovery technology that utilizes waste heat, such as non-condensable gas that are recycled and used as fuel to heat the reactor, further reducing operating expenses.

Fully automated pyrolysis system exhaust gas treatment

Fully automated pyrolysis system exhaust gas treatment

Cons of fully automated pyrolysis system

1.High Initial Investment

Capital Intensive: The upfront cost for purchasing and installing a fully automated pyrolysis system can be substantial, with the reactor price range for a fully automated pyrolysis system reactor is $500,000 to $1,100,000. Financing options and return on investment (ROI) analysis are critical considerations.

2.High cost for raw material

Normally fully continuous process need strict raw material size, like rubber powder should be under 2mm, so you need invest the further process system.

DOING fully automated pyrolysis system

DOING fully automated pyrolysis system

Fully automated pyrolysis system is a trend and is an ideal choice for large-volume processors who prioritize safety, compliance and long-term return on investment. Now the policies of Europe, America, India and other countries have been introduced to require the use of fully automated pyrolysis system. DOING has also helped many customers to establish fully automated pyrolysis system and run them successfully. This is an operation of fully automated pyrolysis system site installed by DOING for your reference:

If you want to invest in a Fully automated pyrolysis system, please contact DOING. DOING will provide you with comprehensive guidance from market profit analysis to plant construction.