Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

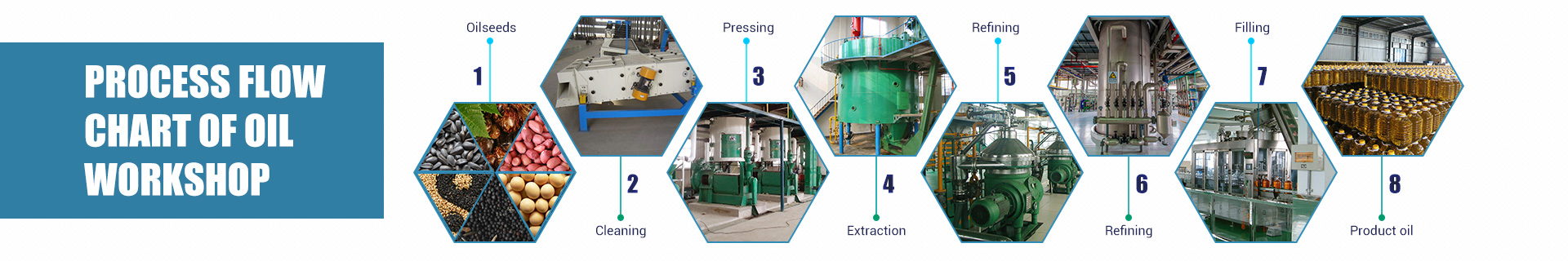

Cooking oil processing plant comprises two parts: oilseeds pretreatment part and cooking oil pressing part. It is the primary section for a cooking oil processing factory.

Different oilseeds need different pretreatment process. Generally speaking, there are several steps: cleaning, husking, crushing, flaking, softening/puffing, cooking process, etc. These process are all in order to adjust oilseeds to the best state before pressing, to increase cooking oil yield and improve cooking oil quality.

Cottonseed oil processing plant built by Henan Doing Company

Cottonseed oil processing plant built by Henan Doing Company

For different oilseeds, the engineers of Henan Doing Company can design the cooking oil processing plant for you. Doing Company can supply 5-2000T/D cooking oil processing plant.

Workflow of different cooking oil processing plant:

Soybean oil processing plant working process:

Soybean → Cleaning → Crushing → Softening → Flaking → Cooking → Pressing → Filtering → Crude soybean oil & soybean cake

Groundnut oil processing plant working process:

Groundnut/peanut → Husking → Cleaning → Crushing → Flaking → Cooking → Pressing → Filtering → Crude groundnut oil & groundnut cake

Rice bran oil processing plant working process:

Rice bran → Cleaning → Crushing → Flaking → Puffing → Cooking → Pressing → Filtering → Crude rice bran oil & rice bran cake

Main equipments used in cooking oil processing plant:

Main equipments used in cooking oil processing plant

Main equipments used in cooking oil processing plant

Cleaning equipment(viberating sieve, magnetic drum, destoner), husking machine, crushing machine, softening pot, flaking machine, puffing machine, cooker, presser, etc.

Business scope of cooking oil processing plant:

1. 5-30T/D small scale cooking oil processing plant

2. 30-500T/D medium cooking oil processing plant

3. 500-2000T/D large scale cooking oil processing plant

Features of DOING Brand cooking oil processing plant:

1. Stable structure

2. Low consumption and high oil yield

3. Easy to operate and maintain

Related products: