Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

If you plan to start your own cotton seed oil mill plant, you may be interested in cotton seed oil extraction process, oil mill plant layout, tips for cotton seed oil mill machine selection, cotton seed cake processing and the cost of setting up a cotton seed oil mill plant. As long as you want to know about these, you can contact us for the more details. Here, I will mainly introduce the equipment and extraction process used in cotton seed oil mill plant.

Cotton seed

Cotton seed

Just like other vegetable oil production, the choice of cottonseed oil processing equipment and extraction process large depend on the daily processing capacity of your oil mill. Generally, the larger the daily processing capacity is, the more complex the cottonseed oil processing equipment and extraction process are. So, it is better to know how many cotton seeds you will process per day before the purchase of cotton seed oil processing equipment.

In general, there are two methods for producing cotton seed oil. The first method is mechanical screw oil pressing, and the second one is pre-pressing & solvent extraction. The second method is suitable for large scale cotton seed oil mill plant, because it can make sure the residual oil rate less than 1%。

1. Equipment in 1-10tpd cotton seed oil mill plant

In 1-10tpd cotton seed oil mill plant, use a set of screw oil expeller to press the cotton seed directly or add a drum roaster to cook the cotton seed for improve the oil yield.

Different models of screw oil expeller

Different models of screw oil expeller

Our screw oil expeller for pressing cotton seed has a variety of models, you can choose a suitable one. And our sales also can help you choose the most appropriate one depending on your situation and requirement.

2. Equipment in 10-50tpd cotton seed oil mill plant

In 10-50tpd cotton seed oil mill plant, you can use pressing method to produce cotton seed oil. The equipment used in 10-50tpd cotton seed oil mill plant contains cotton seed cleaning machine, husking machine, kernel & shell separating machine, flaking machine, cooking machine, oil press machine and oil filter machine.

Equipment and process in 10-50tpd cotton seed oil mill plant

Equipment and process in 10-50tpd cotton seed oil mill plant

The residual oil rate of pressing method is about 6%-7%, which is well known for the people inside the profession. These equipment which is before oil press machine is to process the cotton seeds for obtain better effect for pressing, and the oil filter machine can make sure the quality of the crude cotton seed oil.

3. Equipment in more than 30tpd cotton seed oil mill plant

Above 30tpd cotton seed oil mill plant can use pre-pressing & solvent extraction method to produce cotton seed oil. Pre-pressing refers to that after pretreatment, the cotton seed is pressed by the oil pre-press machine, and make the residual oil rate reach 15%, then send the cotton seed cakes to solvent extraction plant to further process.

Four steps of cotton seed oil solvent extraction plant

Four steps of cotton seed oil solvent extraction plant

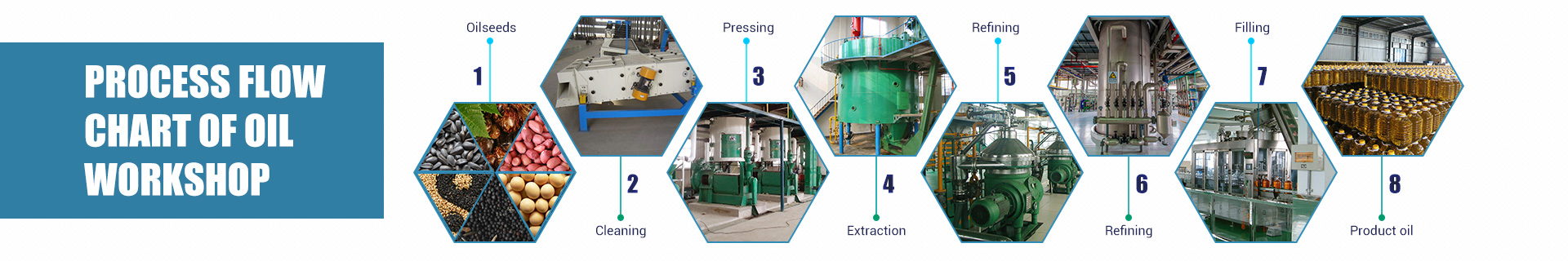

Solvent extraction plant uses n-hexane to extract the cotton seed oil out from the cotton seed cakes, which can extract more oil than pressing method, because at last the residual oil in the dry meal can be less than 1%. Another point I must say is that the oil produce by solvent extraction plant must be refined in oil refinery plant to reach the standard. And our Henan Glory Company also can provide you cotton seed oil refinery machine with different capacities.