Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

Are you interested in starting a palm kernel oil production business? Do you need a professional and practical business plan to guide you? Henan Glory Company will provide you with an in-depth, feasible strategy for establishing a successful palm kernel oil production plant.

Palm kernel oil is widely used in food processing, cosmetics, detergents, and bio-fuels. Major producing countries include Indonesia and Malaysia, while key importers are China, India, the United States, and European countries. As global demand for natural and vegetable-based oils continues to grow, palm kernel oil has emerged as a highly profitable investment opportunity.

So, how do you start your own palm kernel oil production business?

Before launching your palm kernel oil business, conduct thorough market research. Analyze key factors including technical requirements, capital investment, target markets, and rivals. Research regional industry trends and economic data, and study the operations of established palm kernel oil production plants to understand their workflows.

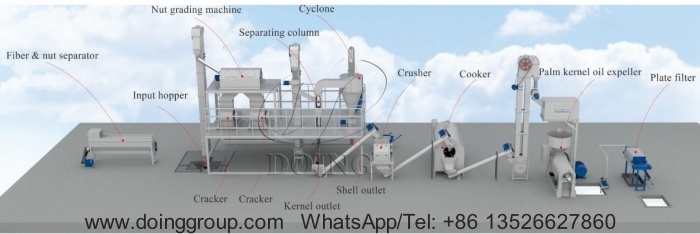

3D diagram of palm kernel oil production line

3D diagram of palm kernel oil production line

Investing in a high-quality palm kernel oil processing plant will save you significant time and costs in the long run. Therefore, it's essential to carefully select the machinery. Our palm kernel oil production plant is equipped with a complete set of core equipment, including kernel crackers, cookers, oil presses, and plate filters. Made of high-quality materials, these equipment are resistant to damage and corrosion. The entire production line is highly automated, enabling continuous operation and efficient extraction.

For small to medium-sized production capacities of 5-30t/d, the physical pressing process is used: first, palm kernels are processed through a fiber separator and kernel-shell separation system to remove impurities; second, they are crushed and fed into a cooker to control temperature and humidity; finally, they are pressed in a kernel oil press, and the crude palm kernel oil is filtered through a plate filter to obtain pure palm kernel oil.

For large-scale production capacities of 30-600 t/d, a "pre-pressing + solvent extraction" process is employed: the palm kernels are crushed and softened, then rolled into flakes. After cooking, they are pre-pressed to extract approximately 85% of the oil, producing pre-pressed crude oil and pre-pressed cake. The pre-pressed cake is then extracted with the organic solvent n-hexane to remove the remaining oil. The palm kernel oil is then evaporated to remove the solvent, obtaining the extracted palm kernel oil. The entire process offers high oil yields and automation, making it suitable for large-scale production.

Large-scale palm kernel oil processing equipment

Large-scale palm kernel oil processing equipment

To operate a palm kernel oil production plant efficiently, you need to recruit competent personnel. The required team typically includes: 1 technician, several assistants, 1 storekeeper, 5-10 general workers, 1 quality control officer, as well as sales, administrative, and security personnel.

Launching a palm kernel oil production business involves certain challenges, such as unstable raw material supply, high machine maintenance costs, and intense market competition. However, with careful planning, reliable equipment, and a strong business strategy, these challenges can be overcome.

Henan Glory Company specializes in the design, manufacture, and export of palm oil production projects, as well as related palm kernel oil production plants. If you are interested in starting your own palm kernel oil production business, feel free to contact us for a customized plan.