Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

Canola seeds, also called rapeseeds, is dark yellow or lighter in color. And the canola oil has rich unsaturated fatty acids and almost 99% of which can be absorbd by human body. In the world, main canola oil processing plants are in Canada, China, India, and Australia. In these countries, canola oil is the third largest source of edible oil, second only to soybean oil and palm oil. So there is no need to worry about the sales channel. If you also want to enter canola oil production industry, and build a canola oil processing plant, please continue to read this article.

Canola seeds and canola oil

Canola seeds and canola oil

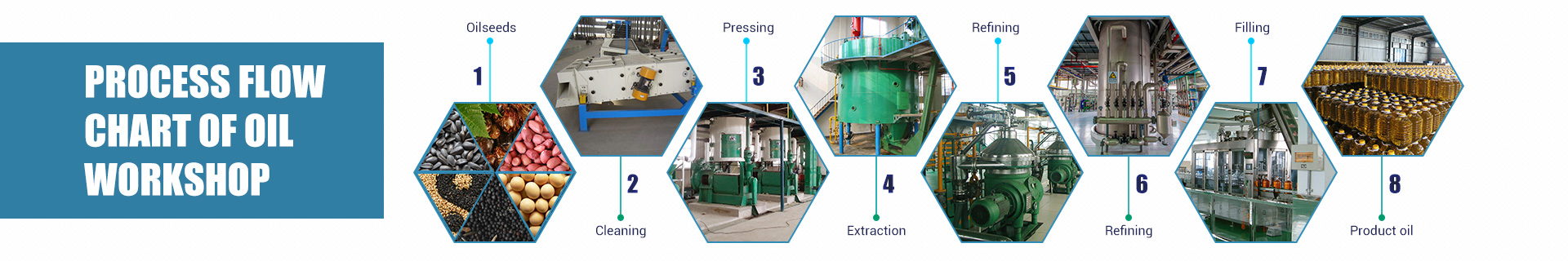

What do you need to do to start a canola oil processing plant? The first thing that you should to know is what machines are needed in canola oil processing plant, which may includes the canola oil extraction plant and the canola oil refinery plant.

The detailed introduction of canola oil extraction plant:

There are two main methods for rapeseed oil processing: pressing method and solvent extraction method. Different production method is selected, there will be differences in equipment configuration. Next, I will introduce the equipment need to be configurate in these two methords.

1 Pressing method:If you choose the pressing methd, the canola oil processing plant mainly need vibrating screen, magnetic separator, destoner, flaking machine, steam cooking machine, expeller machine, filtering machine, as shown in the figure below: :

| The aim is to remove the sand, stone, stem, leaf, etc. from canola seed, which can on one hand assure product quality (oil and cake), on the other hand prevent wearing of other pre-treatment equipment. |

| After flaking, use steam cooking machine to adjust canola seeds temperature and moisture to increase canola seed oil yield; It is also an important procedure in canola oil processing plant. |

| For improving oil yield, canola oil processing must adopts high pressure and steam cooking temperature. Henan Doing canola oil press machine is designed with advanced technology that it’s quite suitable for processing canola oil. |

2 Extraction method:

If you choose the solvent extraction methd, besides above equipement, the canola oil processing plant also should have solvent extractor, evapo-separated machine, steam drying machine, stripping tower, etc. as shown in the figure below:

Canola oil solvent extraction plant

Canola oil solvent extraction plant

In recent years, cooking oil solvent extraction method develops fast, which is based on organic solvent extraction principle and can significantly increase oil yield rate.

The comparative data of canola oil processing plant(pressing and extraction method):

1. Common screw oil presser produce 4-6kg less canola oil per 100kg canola than solvent extraction method, and the crude canola oil quality is poor.

2. Advanced canola oil pre-pressing & extraction plant can first press 25% oil by oil pre-pressers, then the pre-pressed canola oil cake is processed by solvent extraction plant, so that the oil residue of dry canola oil cake can be decreased to 1%.

The detailed introduction of canola oil refinery plant:

Canola oil refinery plant is necessary for the customer who want to get standard canola oil which can be sold in supermarket. Canola oil refinery plant is also the last part of canola oil processing plant, which mainly includes degumming, deacidification, bleaching and deodorization process, etc.

Canola oil refining machine | Degumming: To remove or recycle the hydrophilic phospholipid from canola oil. |

| Deacidification: To purify crude canola oil, which is to add caustic soda solution to the crude oil, and then use centrifuge for separation. | |

| Bleaching: To decrease pigment content of canola oil to the required level, it mainly utilizes certain amount of clay to mix with heated oil under nitrogen environment, then decolorize in decolorization tank. | |

| Deodorization: To destroy peroxides in oil, remove aldehyde, ketone or other air oxidation generated odorous substances that are more easily volatile, and can damage the instable carotene to lighten canola oil color. |

Above all steps are the whole line for canola oil processing plant. Henan Doing can provide you the complete canola oil processing plant and installation instruction, worker training services. Henan Doing Company is looking forword to cooperating with you!