Tel/WhatsApp

Tel/WhatsApp

In recent years, with the continuous enhancement of environmental awareness, waste tyre recycling and utilization have become increasingly prominent. As effective solutions for waste tyre recycling, waste tyre to fuel and RCB pyrolysis plant offer significant potential. If you wish to establish such a plant in South Korea, the following detailed guide may be of assistance.

Waste Tyre Sources: South Korea generates a large number of waste tyres each year. To secure stable waste tyre supplies, in addition to investigating local waste tyre recycling companies, disposal centers, and tyre manufacturers, it is also advisable to explore partnerships with government departments.

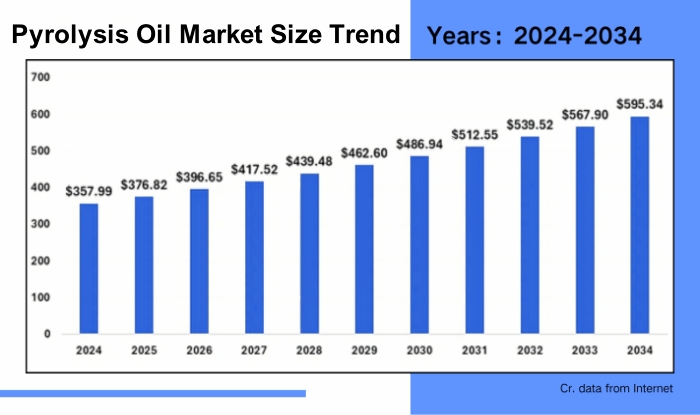

Fuel Oil and Carbon Black Markets: Conduct in-depth research on the demand for fuel oil and carbon black in South Korea. Fuel oil can be sold to power plants, industrial boilers, and other sectors. Carbon black, on the other hand, can be marketed to industries such as rubber manufacturing and plastic processing. When researching market prices and sales channels, it is recommended to consult with local industry associations and professionals, and analyze market trends and development potential to accurately estimate potential profits.

Pyrolysis oil market size trend

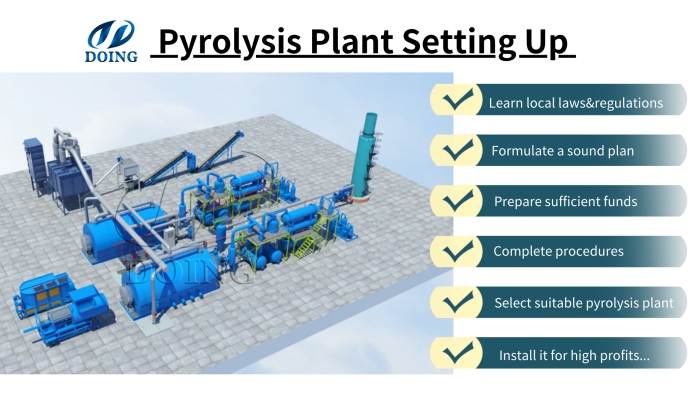

Research Permit Requirements: Visit the official websites of South Korea’s Ministry of Environment and local governments to thoroughly understand the specific requirements and processes for establishing a waste tyre to fuel and RCB pyrolysis plant. Additionally, consult with local legal experts or professional consulting firms to ensure a comprehensive understanding of the regulations.

Prepare Application Materials: Prepare detailed project feasibility reports and environmental assessments, which should include the plant’s construction scale, equipment selection, production processes, environmental protection measures, and potential impacts on the surrounding environment. Submit permit applications to relevant authorities and actively cooperate with government agencies to ensure compliance with all regulations.

Accurately Estimate Funding Requirements: In addition to calculating costs for factory construction, equipment procurement, and operational expenses, also consider potential risks and cost overruns. Equipment costs for waste tyre to fuel and RCB pyrolysis plant may range from tens of thousands to millions of dollars, depending on factors such as equipment specifications and performance. Factory construction costs will vary based on the site location and scale.

Evaluate Site Conditions: Select a location away from residential areas with convenient transportation, adequate water and electricity supply, and sufficient space for waste tyre storage. Additionally, consider local land policies and costs to reduce factory construction expenses.

Take a semi-continuous pyrolysis plant with a daily processing capacity of 10 tons as an example. The overall factory layout includes waste tire storage areas, pyrolysis production zones, oil storage areas, and carbon black processing zones. The total land requirement is approximately 450-600 square meters.

Align with Raw Material and Market Distribution: Choose a site close to waste tyre sources and target markets to lower transportation costs and improve operational efficiency.

Waste tyre to fuel and RCB pyrolysis plant setting up conditions

Choose a Reliable Supplier: As a pyrolysis plant manufacturer, we recommend selecting suppliers with strong technical capabilities, excellent reputations, and comprehensive after-sales services. Before finalizing a supplier, visit their facilities to inspect equipment quality and performance, and review user feedback to ensure their credibility and reliability.

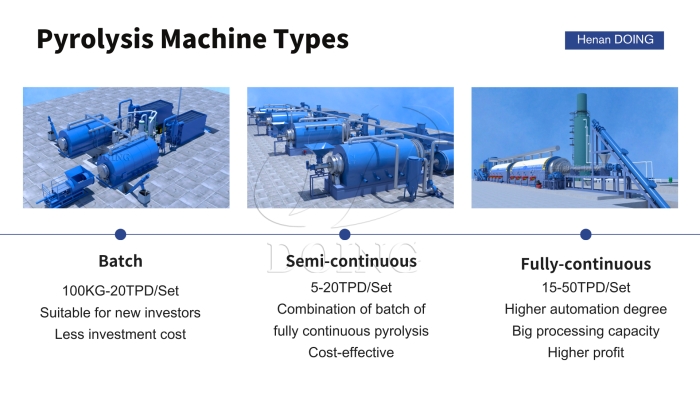

Focus on Equipment Quality and Specifications: Currently, there are three main types of waste tire pyrolysis plant on the market:

Batch Pyrolysis Plants: These are simple in structure, low in investment, and easy to operate. However, they require downtime for loading and unloading, resulting in lower production efficiency. They are suitable for small-scale production.

Semi-Continuous Pyrolysis Plants: These combine the advantages of batch and continuous plants. They feature continuous feeding and batch discharging, offering higher production efficiency and stability than batch plants. They are ideal for medium-scale production.

Continuous Pyrolysis Plants: These boast high automation, continuous feeding and discharging, and high production efficiency. However, they require higher investment and strict operational conditions, making them suitable for large-scale production.

DOING waste tyre to fuel and RCB pyrolysis plant types

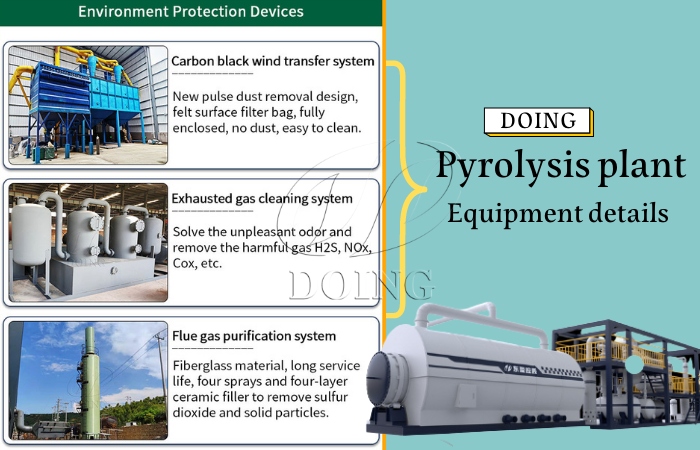

Comply with Environmental Regulations: Install pollution control equipment such as waste gas treatment systems, exhaust gas recovery, waste purification, dust removal, desulfurization and other equipment to ensure emissions meet South Korea’s environmental standards. Regularly monitor emissions and submit reports to environmental authorities.

Implement Safety Measures: Establish strict safety management systems and operational procedures. Conduct regular safety inspections and hazard assessments to prevent accidents.

DOING waste tyre to fuel and RCB pyrolysis plant environment protection devices

Establishing a waste tyre to fuel and RCB pyrolysis plant in South Korea requires thorough preparation and meticulous execution. As a professional pyrolysis plant manufacturer, DOING Company is committed to providing high-quality equipment and comprehensive technical support to help you navigate the setup process and achieve success in South Korea’s waste tyre recycling industry.