Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

Do you know groundnut oil manufacturing process? In our daily life, groundnut oil is one of the most common cooking oil. And the oil content of groundnut is very high, about 40%-50%. So groundnut oil manufacturing process machinery is the major cooking oil equipment that we research and design all the time.

Doing Company groundnut oil manufacturing process machinery are advanced oil processing machinery, characterized by high technology, high quality and low price. And groundnut oil press process machinery can also be used for making peanut oil, soybean oil, rapeseed oil, sesame oil, olive oil, sunflower oil, coconut oil, cottonseed oil and corn germ oil.

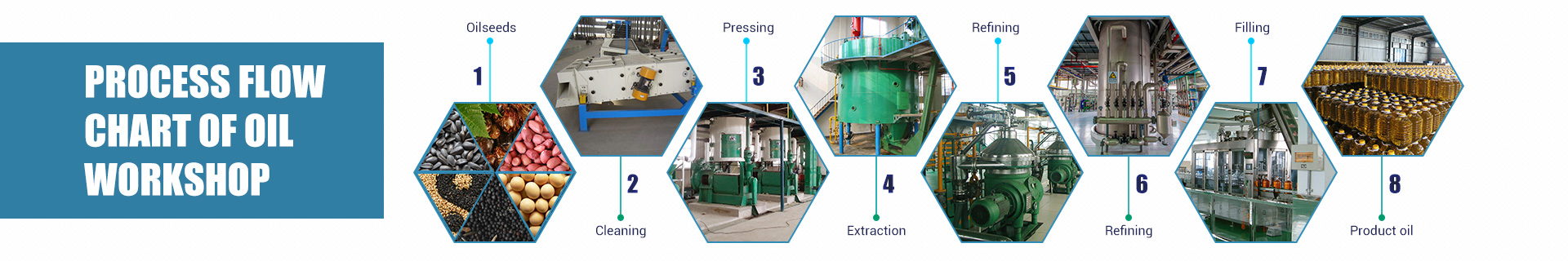

Complete set groundnut oil manufacturing process machinery

In the whole groundnut oil manufacturing process, the first step is oil seeds pretreatment. As shown above on the picture, five kinds of machines are used before pressing. The detailed introduction of these five kinds of machines is as following.

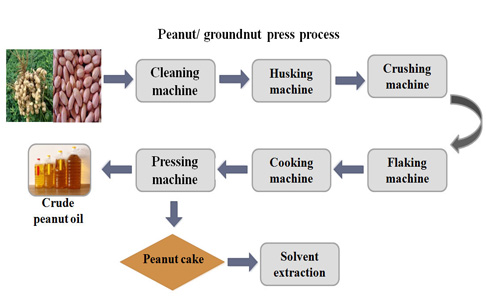

The work flow of groundnut pretreatment and pressing plant:

Groundnut → Cleaning → Crushing → Softening → Flaking → Cooking → Pre-pressing → Solvent extraction workshop

Groundnut pretreatment and pressing process

As the following description, the machines used in groundnut pretreatment and pressing plant all have important effects.

a. Cleaning device:

To remove the various impurities in peanut/groundnut, such as: iron, stones, clump, such as the plant leaf, clean up till impurity content does not exceed 0.2%.

b. Crushing machine:

In order to meet the requirements of groundnut oil manufacturing process, the peanut should be broken into small pieces.

c. Softening machine:

To adjust the moisture and temperature of oil, and make it soft.

d. Flaking process:

Rolling raw material into flakes, and the purpose is to increae surface area, destroy the peanut cell tissue, shorten the way of oil out from cake.

e. Cooking machine:

Use steam cooking, inject direct steam and cook the flakes to meet the requirement of groundnut oil manufacturing process.

f. Pre-press machine:

Press the flakes to leave about 16%-18% in the cake. The cake will go to solvent extraction workshop.

Note: Read more detailed information Cooking oil pretreament machine.

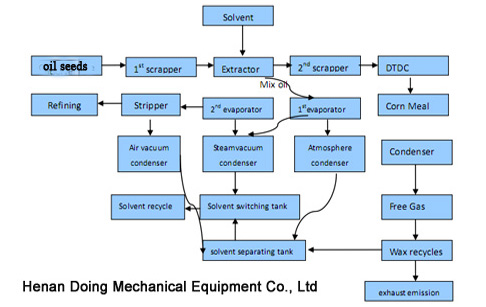

In the whole groundnut oil manufacturing process, the second step is groundnut oil solvent extraction plant. This picture bellow showns the process of groundnut oil solvent extraction plant.

Groundnut oil solvent extraction process

Groundnut oil solvent extraction plant includes four system: solvent extraction system, D.T.D.C system, mixed oil evaporation system and condenser & recovery system. The main equipment introduction as following.

1. Roary extractor: Spray and soak the pretreatment peanut/groundnut with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil) .

2. DTDC:

It is usd to separate the solvent from the wet meal.

3. Miscella tanks:

It is uesed for purifying miscella will be pumped into it.

4. 1st evaporator, 2nd evaporator:

Used to separate the solvent from the oil. After this process,the solvent can be removed 85%.

5. Miscella stripping:

It will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

6. Condensers:

Used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Note: Read more detailed information Groundnut oil extraction process machinery.

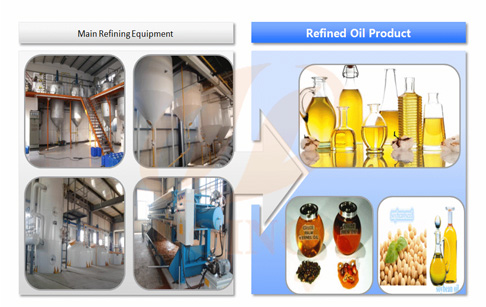

In the whole groundnut oil manufacturing process, the third step is groundnut oil refinery plant. Our groundnut oil refinery plant is used to refine the crude groundnut oil, get rid of the deleterious impurity, and then get the high quality groundnut oil. According to the different capacity, the groundnut oil refinery plant can be devided three types: batch type refinery plant, semi-continuous type refinery plant, and fully-continuous type refinery plant.

Cooking oil refining machine

Note: Read more detailed information Edible oil refinery plant.

There are three advantages about our groundnut oil manufacturing process machineery.

1.Our groundnut oil manufacturing process machinery have the high quality and high performance. we use the stainless steel instead of the carbon steel.

2.We are the professional manufacturer of cooking oil processing machine, we can guaranteeing the quality of peanut /groundnut oil pretreatment machine ,groundnut oil solvent extraction plant and groundnut oil refinery plant.

3.Our welding workers have get the certificates.

If you are interested in our groundnut oil manufacturing process machinery, please contact us when you are free, and our engineer will give you a feasibility program according to your request.