Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

100-500tpd cooking oil refinery equipment is full-continuous cooking oil refinery equipment. Basing on the traditional cooking oil refinery equipment technology, Henan Doing Mechanical Equipment Co.,ltd has developed the latest combined packing layer plate deodorization tower and the physical and chemical mixed refining technology for crude oil of any quality. Moreover, a series of advanced technology and equipment are used, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization.

Different capacities of cooking oil refinery equipment

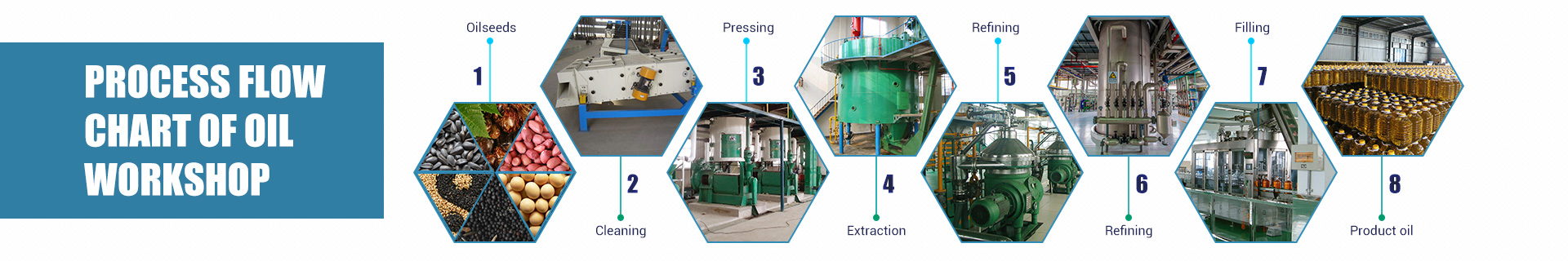

Process introduction of cooking oil refinery equipment:

Crude oil--Degumming--Neutralize--Decoloring--Deodorizing--Cooling--Dewaxing--Final oil

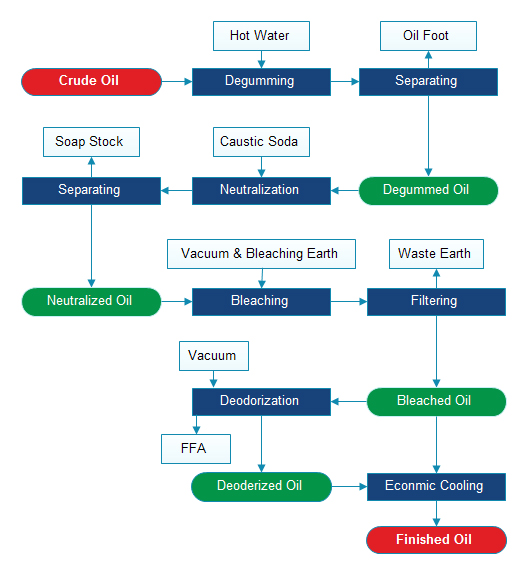

The flowchart of cooking oil refinery equipment

Degumming section of cooking oil refinery equipment:

This is the first step in refining and is also known as the pretreatment process. In the degumming process of 30-500tpd cooking oil refinery equipment, the gums are precipitated and separated by the centrifugal separation technique. If the gum content in the oil is low, only gum-conditioning is required to be done and there is no need to go for separate degumming process. The degumming can be carried out in the same neutralization vessel.

Neutralizing section of cooking oil refinery equipment:

Crude cooking oil contains much free fatty acid, which is harmful for health. Free fatty acid can have reaction with caustic soda. During the reaction, it can be saponified and becomes soap stock, then small soap stock pellets will sink and become sediment and be pumped out. After neutralizing, most of the free fatty acid will be removed out.

Decoloring section of cooking oil refinery equipment:

The main function of decoloring process is to remove oil pigment, residual soap grain and metal ions. Under negative pressure, the mechanical mixing method combined with steam mixing will improve the decoloring effect. The degummed oil firstly enters into the heater to be heated to the appropriate temperature (110°C), and then goes to the bleaching earth mixing tank. The bleaching earth is delivered from the low bleaching box to the temporary tank by wind. The bleaching earth is added by automatic metering and is interlockingly controlled with the oil.

The oil mixed with the bleaching earth overflows into the continuous decolorizer, which is stirred by non-powered steam. The decolored oil enters into the two alternate leaf filters to be filtered. Then the filtered oil enters the decolored oil storage tank through the security filter. The decolored oil storage tank is designed as the vacuum tank with the nozzle inside, so as to prevent the decolored oil contacting with the air and influencing its peroxide value and color reversion.

Deodorizing section of cooking oil refinery equipment:

The qualified decolored oil enters into the spiral plate heat exchanger to recover most of the heat, and next goes to high pressure steam heat exchanger to be heated to the process temperature (240-260°C) and then enters the deodorization tower. The upper layer of combined deodorization tower is the packing structure which is mainly used to remove the odor producing components such as free fatty acid (FFA); the bottom layer is the plate tower which is mainly for achieving the hot decoloring effect and reducing the peroxide value of the oil to zero. Oil from the deodorization tower enters into the heat exchanger to recover most of the heat and makes further heat exchange with crude oil, and then is cooled to 80-85°C through the cooler. Add the required antioxidant and flavor agent, and then cool the oil below 50°C and store it. Such volatiles as FFA from the deodorizing system are separated by the packing catcher, and the separated liquid is FFA at low temperature (60-75°C). When the liquid level in the temporary tank is too high, the oil will be sent to the FFA storage tank.

Note: Learn more Deodorization process of cooking oil refining line

Deordorization tower of 500tpd cooking oil refinery equipment

Our services

Our company always put the interests of customers, product quality and service as first, and always adhere to the"Customer’s success is our biggest wishes" as our purpose. We will be commitment to provide high quality products with perfect service. Now the specific commitments are as follows:

1. Ensure provide complete sets of equipment and accessories timely.

2. Ensure that one-time installation debugging acceptance.

3. To provide high quality material with preferential price.

4. Priority to provide customer our new craftworks and products.

5. Free training technological operator to ensure the trained staff can operation independently.

6. In the installation process,we will appoint an installation supervision staff on the spot.

7. We will offer an experienced project manager, organize a good installation team for the work.

Our company is a professional cooking oil refinery equipment manufacturer, and we can produce 1-2000tpd cooking oil refinery equipment. Our engineer will design the refining machine according to your condition. Welcome to write down your message!