Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

For cooking oil processing machine, according to the different processing capacity, you can choose stand-alone machine such as cooking oil press machine or cooking oil production line; according to different cooking oil processing methods, you can also cooking oil solvent extraction machine. Next, Henan Glory Company will give you a detailed introduction about several options for cooking oil processing machine.

1. Cooking oil press machine

If your processing capacity is small, we have three types of oil presses, there are cold presses, automatic temperature control oil presses, air pressure filter combination oil presses.

Cooking oil press machine

Cooking oil press machine

The cold press machine only has the function of extracting oil, and is often used for cold pressing to retain the nutrients in the oil. The automatic temperature control oil press comes with a roaster, which can automatically adjust the oil output temperature and improve the oil output rate. Air pressure filter combination oil press comes with a roaster and two vacuum filter barrels, which can realize the integration of cooking and filtering, which is more convenient.

2. Cooking oil production line

If your processing capacity is large, we also have the whole production line for you to choose, which includes machines such as cleaning machine, kernel shell separator, flaking machine, roaster, oil press and filter, etc. The specific production process is as follows:

Cooking oil production line

Cooking oil production line

(1) Use cleaning machine to remove impurities in oilseeds. Common cleaning machine includes magnetic separators, cleaning screens, destoner, etc.

(2) Separate the oilseed kernel and shell with a kernel shell separator.

(3) Using flaking machine and roaster to adjust the temperature, humidity and internal structure of oilseed is more conducive to oil production.

(4) Squeeze the oilseeds with an oil press to get oil, and if you want to get more oil, you can perform secondary pressing.

(5) Use a filter to remove impurities and part of the water in the crude cooking oil.

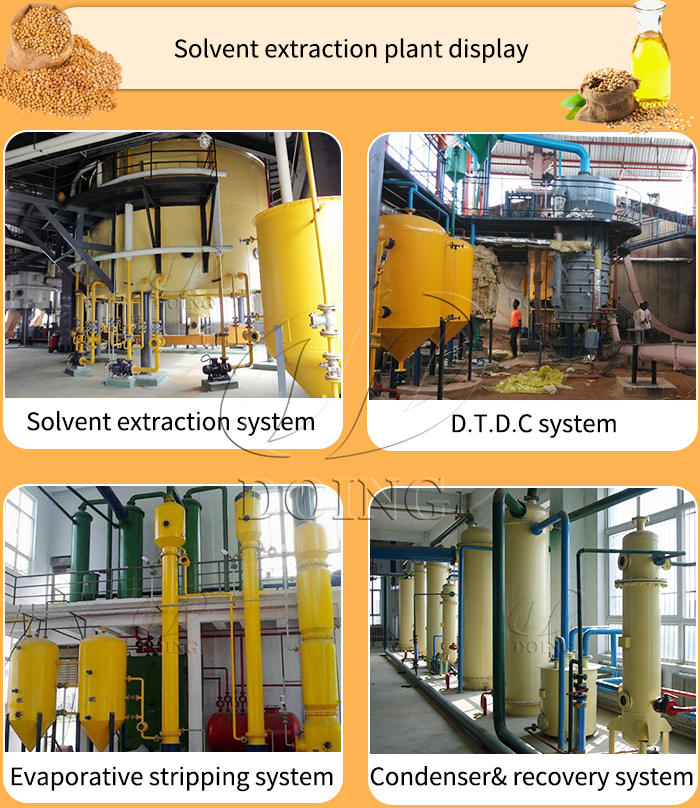

3. Cooking oil solvent extraction machine

Cooking oil solvent extraction plant

Cooking oil solvent extraction plant

The production of cooking oil by solvent extraction also requires cleaning machine, shelling machines, flaking machines, roaster, etc. to process oilseeds, adjust the internal structure of oilseeds, and improve the production efficiency of oilseeds. Then, a prepress is used to obtain the oil and filter cake. The filter cake needs to be transported to the solvent extraction plant for further cooking oil production. Solvent extraction includes extraction section, miscella evaporation and stripping section, dissolving baking powder section, and solvent recovery section.

If you want higher quality cooking oil, you can use cooking oil refining machine to refine crude cooking oil. Henan Glory Company specializes in the development of cooking oil processing machine. We are mainly engaged in cooking oil pretreatment, pressing, refining, solvent extraction, fractionation, winterization, dewaxing, etc. If you want to engage in cooking production business, please feel free to contact us.