Tel/WhatsApp

Tel/WhatsApp

Doing Holdings Co., Ltd

Doing Holdings Co., Ltd

Palm oil refinery machines :

Simple in structure and stable in performance;

Additional horizontal grid plate prevents the miscella against flowing back to material cell and thus to ensure good extraction effect;

Raw material level control ensures consistent feeding, and keeps constant material level in the material vessel to prevent the solvent vapor overflowing outside.

The wet meal is discharged by Material Discharger. Which continuously discharge the wet meal onto the Wet Meal Conveyor. This can not only buffer impacting to conveyor, but avoid meal bridging, un-uniform wet meal discharging and extends service able lift of Wet Meal Conveyor.

Main equipments and refining processes of palm oil:

1.Decolour tank is for bleaching grease.

2.Deodorizing tank is for desdorizing grease(stainless steel).

3.Conducting oil furnace provide thermal enery need for production, the temperature reach to 280degree.

4.Vacuum pump provides vacuum for bleaching, deodorization which can reach 755mmHg or more;

5.Air compreassor can dry the bleached clay

6.Air press is for filter clay

7.Steam generator can generate steam distillation required.

8.This kind of oil refining eqiupment make the oi reach the standard level national edible oil.

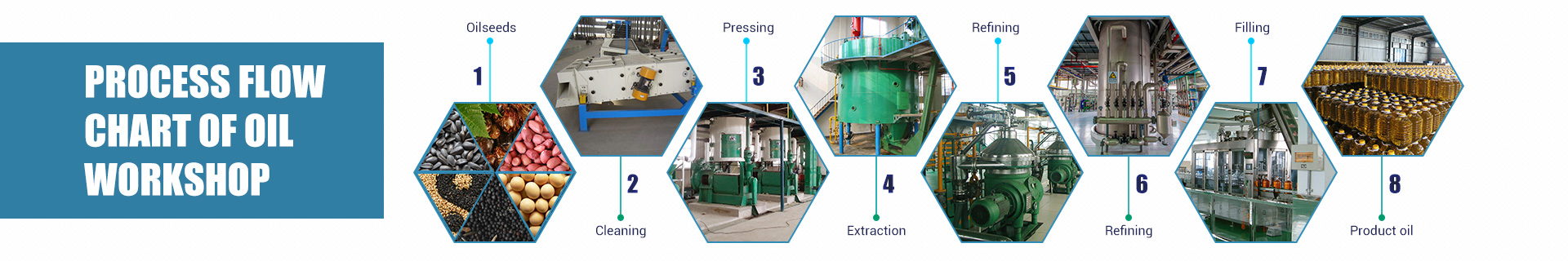

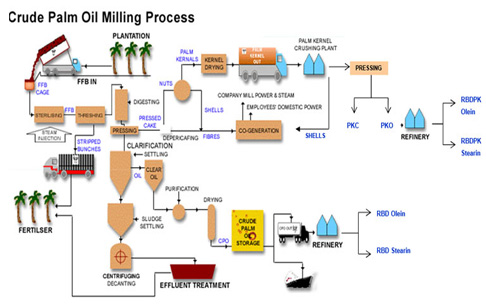

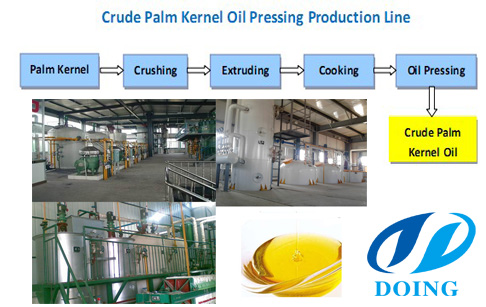

Flow chart of palm oil refinery:

Palm oil refinery chart flow

Main parts of palm oil refinery line:

de-mixed, degumming, dehydration, deacidification, decolorzation, dewaxing and deodorization.

Palm oil refinery machine

Palm oil refinery machine and crude palm oil refining chart flow

Characters of our palm oil refinery machines:

A.Safety:

1. we using auto welding machine to make the reactor,which can quarrantee the quality of welding seam,avoid cracking and has a long life for about 8 years.

2. professional heating treatment and x-ray detection chamber for welding seam .

3. vacuum system to prevent oil gas be back to reactor causing accident.

4. with professional thermometer , professiona pressure gauge and safety valve.

B.Environment friendly:

1.dedusting system to prevent gas and dust from coal burning

2.the exhaust gas will be recycled for heating reactor ,no gas pollution

3.well sealing on every junction parts to prevent gas leak,no smelly

C.Longer life :

Using Q345R special steel plate ,welding seam with auto welding an will get heating treatment and x-ray detection to extend the life of reactor to the most extend, and the life will 8 years

D.Energy saving:

1. well sealing for heating system ,no gas leak and saving fuel.

2. the exhaust gas will be recycled for reactor heating

Palm oil refinery machine

Palm oil refinery machine

Our company is one leading producer of oil equipments in China, also one unit exempt from quality examination.We are committed to bringing in new technology , renewing products, keeping leading in this filed.If you have any questions about the palm oil machines and cooking oil machines,please feel free to contact us!